Pulullan hollow capsule

A pullulan polysaccharide and hollow capsule technology is applied in the field of pullulan polysaccharide hollow capsules, which can solve the problems of low pullulan polysaccharide and uncontrollable disintegration time within a certain time, and achieve simple ingredients and controllable disintegration time. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

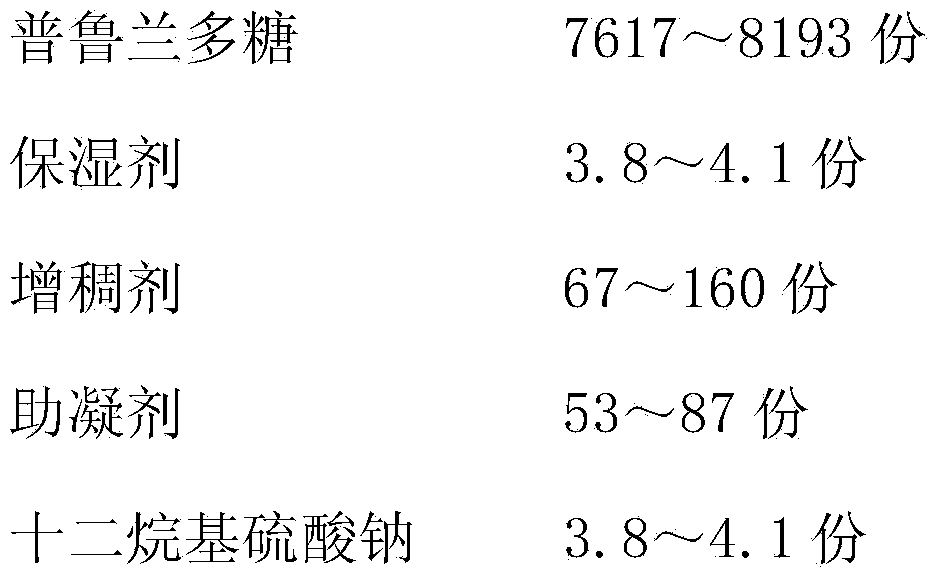

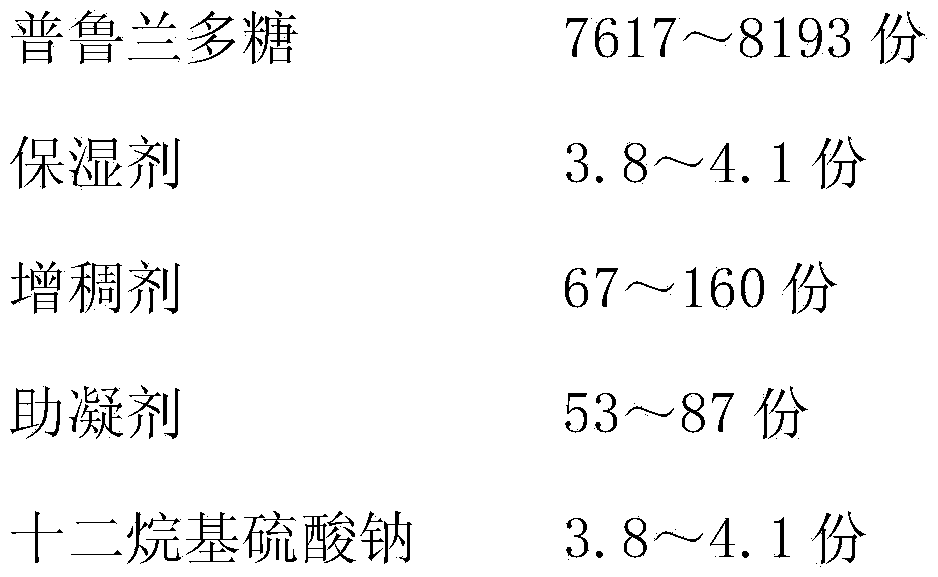

[0026] A pullulan hollow capsule is prepared by the following preparation steps: first, 3.8 parts of glycerin, 67 parts of potassium chloride, 160 parts of carrageenan and 3.8 parts of deionized water are sequentially added to 1500 parts by mass of deionized water. Sodium dialkylsulfate and stir until uniformly dispersed; then add 38,500 parts by mass of deionized water at 80°C, and stir until the system is completely dissolved; then add 7617 parts of pullulan while stirring after the solution is clarified, and The glue is fully stirred, the stirring speed is 50r / min, the stirring time is 30min, and the glue is kept at 70°C for 4h, and at 55°C for 7h; finally, the glue is molded through a dipping mold, and the glue is molded at a temperature of 28°C. Dry at ℃ for 120 minutes to obtain a rubber base, and then demould, cut and fit the rubber base to obtain a hollow capsule.

[0027] After testing, the water content of the hollow capsule is 10wt%, the disintegration time limit of...

Embodiment 2

[0029] A pullulan hollow capsule is prepared by the following preparation steps: First, 3.9 parts of polyethylene glycol, 80 parts of potassium chloride, 67 parts of carrageenan and 3.9 parts of Parts of sodium lauryl sulfate and stirred separately until uniformly dispersed; then added 38500 parts by mass of deionized water at 90°C and stirred until the system was completely dissolved; then added 7904 parts of pullulan while stirring after the solution was clarified For polysaccharides, fully stir the glue solution with a stirring speed of 55r / min and a stirring time of 40min, and keep the glue solution at 70°C for 5 hours, and keep it at 50°C for 8 hours to defoam; Dry at a temperature of 27°C for 150 minutes to obtain a rubber base, and then demould, cut and fit the rubber base to obtain a hollow capsule.

[0030] After testing, the water content of the hollow capsule is 12wt%, the disintegration time limit of the hollow capsule is 4min, and the success rate is 99.0%.

Embodiment 3

[0032] A pullulan hollow capsule is prepared by the following preparation steps: First, 3.9 parts of glycerin, 53 parts of potassium chloride, 133 parts of carrageenan and 4.0 parts of deionized water are sequentially added to 1500 parts by mass of deionized water. Sodium dialkylsulfate and stir until uniformly dispersed; then add 38500 parts by mass of deionized water at 85°C, and stir until the system is completely dissolved; then add 7896 parts of pullulan while stirring after the solution is clarified, and The glue is fully stirred, the stirring speed is 60r / min, the stirring time is 25min, and the glue is kept at 75°C for 4h, and at 55°C for 6h; finally, the glue is molded through a dipping mold, and the glue is molded at a temperature of 29°C. Dry at ℃ for 160 minutes to obtain the rubber base, and then the rubber base is demoulded, cut and fitted to obtain a hollow capsule.

[0033] After testing, the water content of the hollow capsule is 11wt%, the disintegration time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com