NdFeB permanent magnet temperature compensation material for wind power generator or permanent magnet motor

A technology of permanent magnet motors and wind power generators, applied in the direction of magnetic circuits characterized by magnetic materials, can solve problems such as surface scratches, complicated processes, and increased production costs, so as to achieve resistance to impact deformation, rapid heat diffusion, and maintenance The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described in detail below through examples, but the present invention is not limited only to the following examples.

[0023] The NdFeB permanent magnet body of the present invention is a commercially available product, such as the material brand sold by Shanxi Liteng High-Tech Magnetic Industry Co., Ltd.: N48H NdFeB, as long as it is suitable for NdFeB on wind power generators or permanent magnet motors Boron permanent magnets are applicable to the present invention.

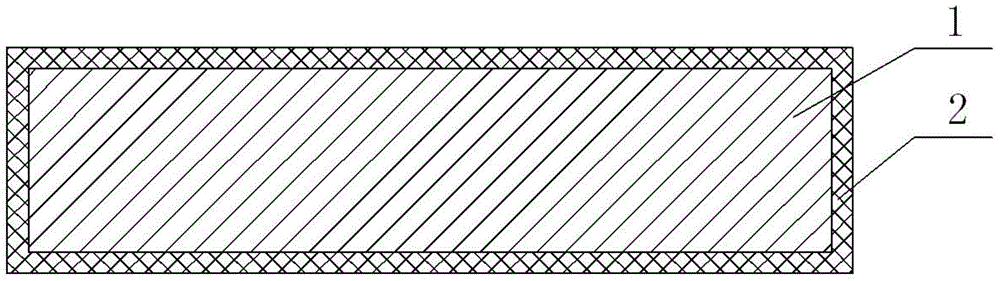

[0024] Such as Figure 1-2 The shown NdFeB permanent magnets for wind power generators or permanent magnet motors of the present invention include NdFeB permanent magnets 1, and the outside of the NdFeB permanent magnets 1 is coated with a metal shell 2; its processing The specific implementation of the method is as follows:

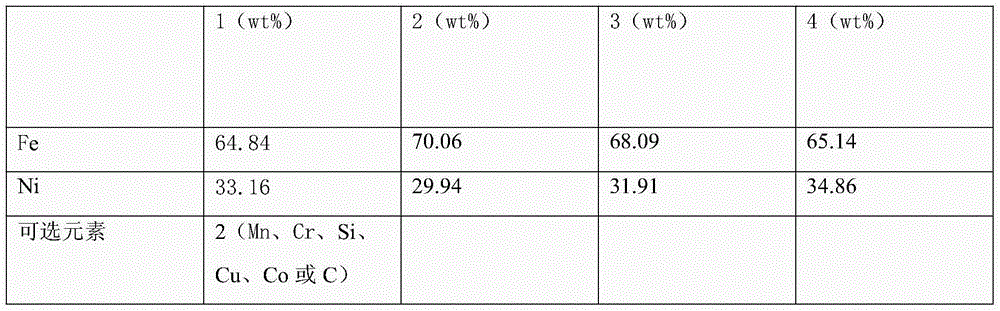

[0025] Firstly, the metal shell is prepared according to the following formula:

[0026] Table 1 Metal shell formula

[0027]

[0028] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com