Method for manufacturing thin film transistor and thin film transistor

A technology of thin-film transistors and polysilicon layers, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., to achieve the effect of simplifying the manufacturing process and satisfying precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

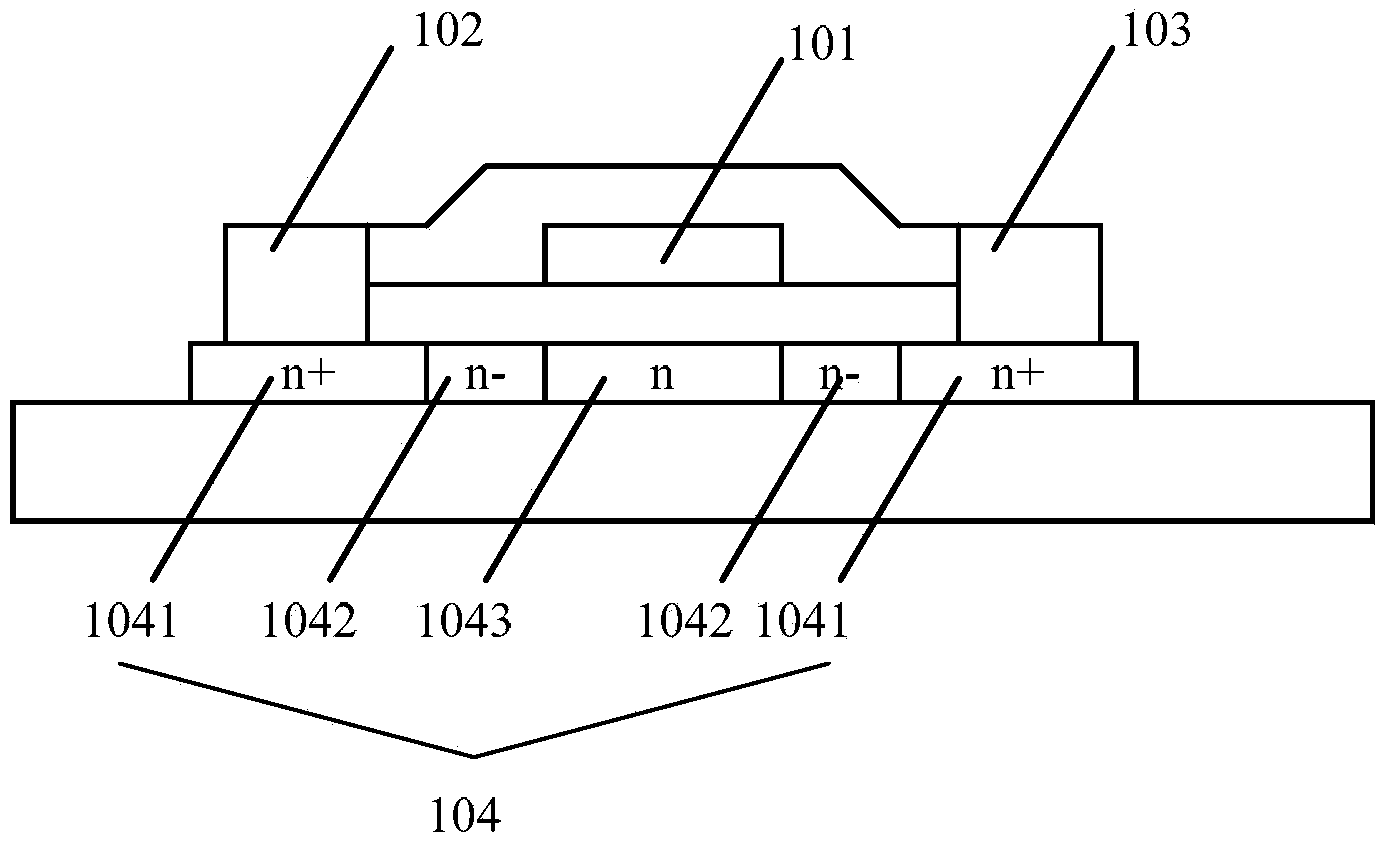

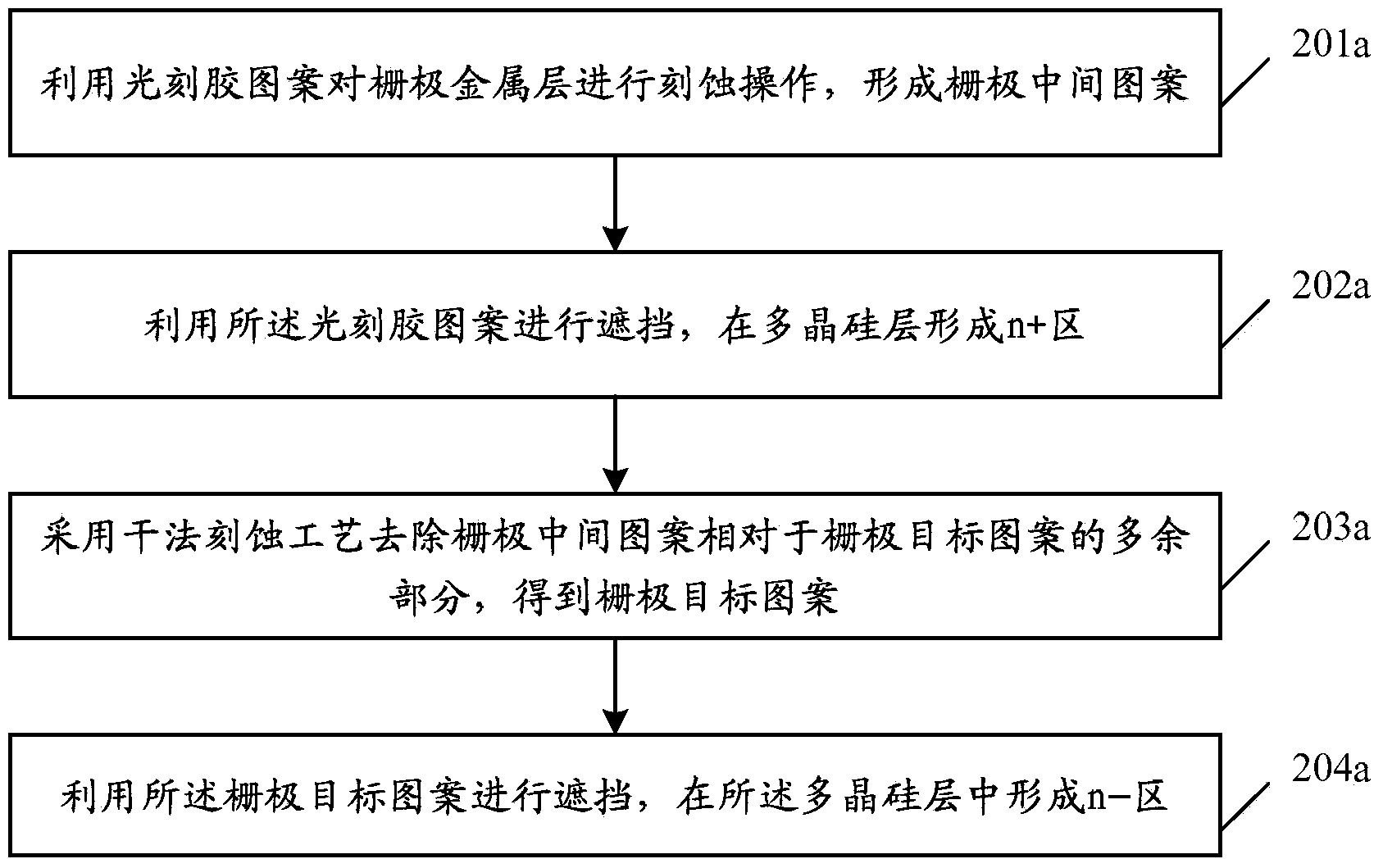

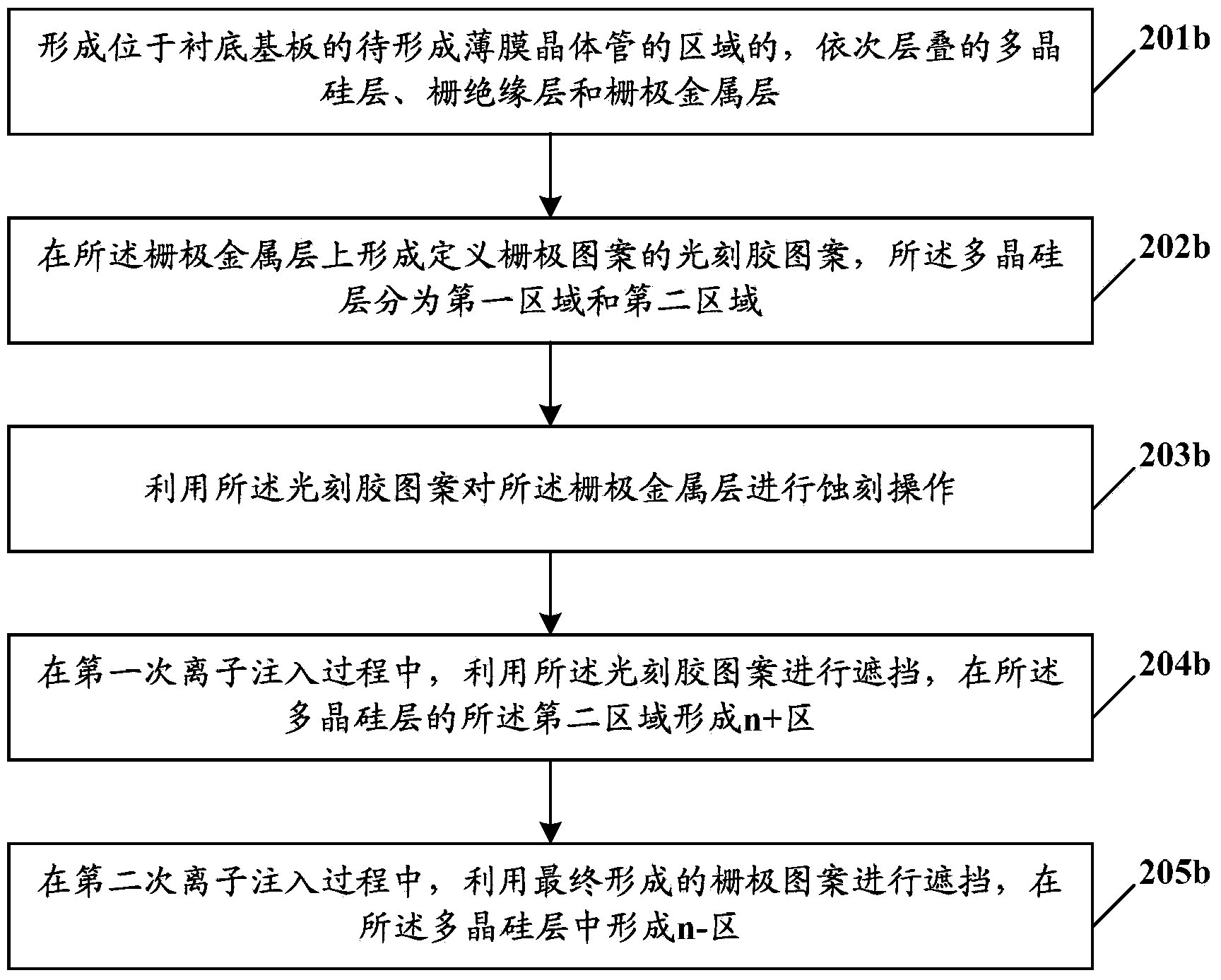

[0041] In the embodiment of the present invention, when forming the n+ region and n- region of the LTPS TFF, the above-mentioned n+ region and n- region are formed by using the photoresist defining the gate pattern and the gate target pattern as shields respectively. The resist precision and gate target pattern precision are controllable, so that the precision of the n-region can meet the precise control of the LDD structure size of the low-temperature polysilicon thin film transistor, and simplify the manufacturing process of the LTPS TFF.

[0042] Before the method of the embodiment of the present invention is described in detail, several process flows involved in the embodiment of the present invention are briefly described, so as to better understand the embodiment of the present invention.

[0043] In semiconductor manufacturing, it is necessary to use selected images, graphics or objects to block the film layer to be processed in order to control the active area of etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com