Connecting structure for LED (light-emitting diode) light strip efficacy high-efficiency conversion hollow glass curtain walls

A technology of LED light strips and glass curtain walls, applied in walls, building components, building structures, etc., can solve the problem of butt connection of LED light-emitting transparent curtain walls, solve the problem of heat dissipation of LED chips, and solve the thermal expansion coefficient of surface glass etc. to achieve the effects of reducing energy consumption, improving light conversion efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

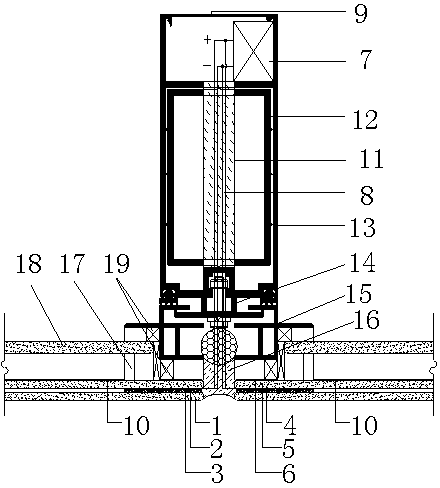

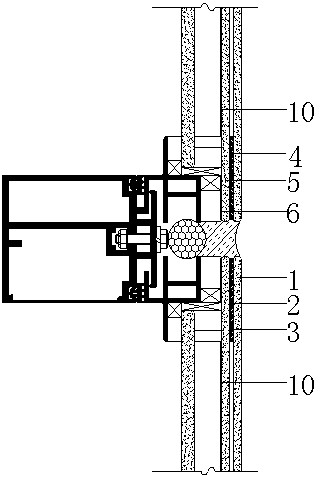

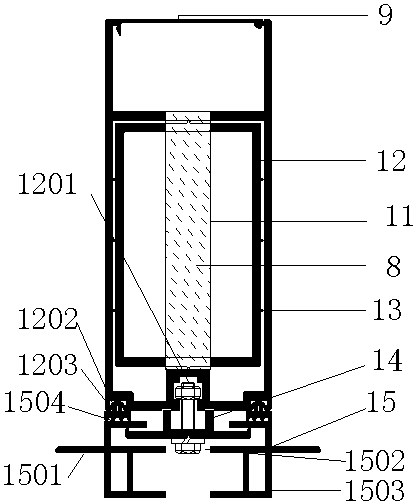

[0012] Embodiment 1: with reference to attached Figure 1-3 . A hollow glass curtain wall connection structure for efficient conversion of LED light strip performance. The aluminum alloy sleeve 12 is fixed on the aluminum alloy column 13, and the middle part of the front surface of the aluminum alloy sleeve 12 is a bolt cap clamping groove 1201, and the two sides of the front surface are aluminum alloy. Alloy sub-frame clamping slot 1202, the rear end is a controller installation slot, and an aluminum alloy pressure plate 9 is arranged on the slot; the aluminum alloy sub-frame 15 is composed of a front-end slot frame 1503, a support plate 1501 and a rear-end slot frame 1504, and the front-end slot frame 1503 is the bonding frame of the hollow glass curtain wall for efficient conversion of LED light belt performance, and the rear end frame 1504 is inserted with an aluminum alloy pressing block 14 and passes through the front frame 1503, the bolt hole 1502 in the support plate 1...

Embodiment 2

[0014] Embodiment 2: On the basis of Embodiment 1, the first surface of the quartz glass layer is a frosted glass surface, in order to minimize reflection.

[0015]One of the manufacturing methods for efficient conversion of LED light strips to insulating glass: (1) According to the size of the LED lattice glass mold belt layer, a conductive metal lattice mesh belt 3 with positive and negative poles is made, and then the heat-absorbing glass is heated to the melting softening point Finally, press the conductive metal lattice mesh belt 3 with positive and negative poles into one side or two sides or three sides or four sides of the melted and softened heat-absorbing glass surface; (2) There is a layer of heat-absorbing glass on the back Heat dissipation layer 10; (3) Paste the LED chip 4 on the intersection point of the conductive metal dot matrix mesh belt 4 and form the LED dot matrix glass mold belt layer 5, and then cover the PVB or EVA film 2 on the LED dot matrix glass mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com