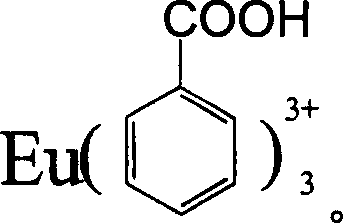

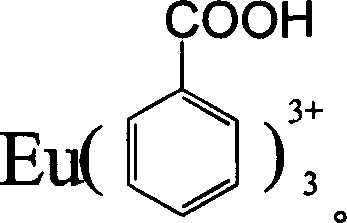

Weather resistant light-converting luminous farm film and its making process

An agricultural thin film and weather resistance technology, applied in chemical instruments and methods, luminescent materials, plant protection covers, etc., can solve the problems of narrow light conversion spectrum, low light conversion efficiency, and high production cost of rare earth organic coordination compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] The present invention also provides the preparation method of described thin film, and it comprises steps:

[0090] (a) 0.01-2 parts by weight (preferably 0.05-1.5 parts by weight) of visible light excited long-lasting light-changing agent A, 0.01-1 part by weight (preferably 0.05-0.5 parts by weight) of red light-changing agent B, 0.01-1 weight part (preferably 0.05-0.5 weight part) of blue light conversion agent C and 0.1-2 weight part (preferably 0.02-1.5 weight part) of anti-aging agent D are mixed together to form a mixture ;

[0091] (b) mixing the mixture in step (a) with 80-100 parts by weight of matrix resin, and making a film.

[0092] In a preferred example, the manufacturing method includes the steps of: first, take visible light excited long-lasting light-changing agent A accounting for 0.01-2% by weight of the matrix resin, taking light-changing agent B accounting for 0.01-1% by weight of the matrix resin, and taking 0.01-1% of the weight of the matrix re...

Embodiment 1

[0103] Preparation of agricultural film No.1

[0104] Weigh raw materials according to the table:

[0105] Table 1

[0106]

[0107] Disperse the above components in 20 parts of acetone, mix them evenly and dry them, then add 100 parts of LDPE (low density polyethylene), after high-speed stirring, use a twin-screw extruder to granulate to obtain fluorescent additives and anti-aging agent masterbatches . Mix the obtained masterbatch with 450 parts of LDPE, mix evenly, and then use an extrusion blown film machine to blow mold it into a film with an average thickness of 0.12 mm, which is called Agricultural Film No.1.

Embodiment 2-5

[0109] Preparation of agricultural film No.2-5

[0110] The method described in Example 1 was repeated, except that the ingredients and contents (parts by weight) shown in Table 2 were used.

[0111] Example 1

[0112] As a result, agricultural films No.2-No.5 with an average thickness ranging from 0.10-0.15mm were produced

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com