One-bath low-temperature desizing, refining and pre-bleaching method for cotton woven fabrics

A fabric and desizing technology, applied in the field of dyeing and finishing, can solve the problems of fiber damage, high energy consumption and high cost, and achieve the effects of avoiding fabric damage, shortening the process flow, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

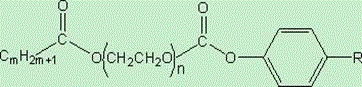

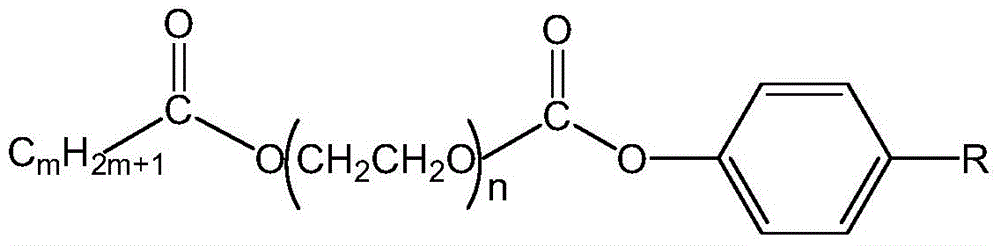

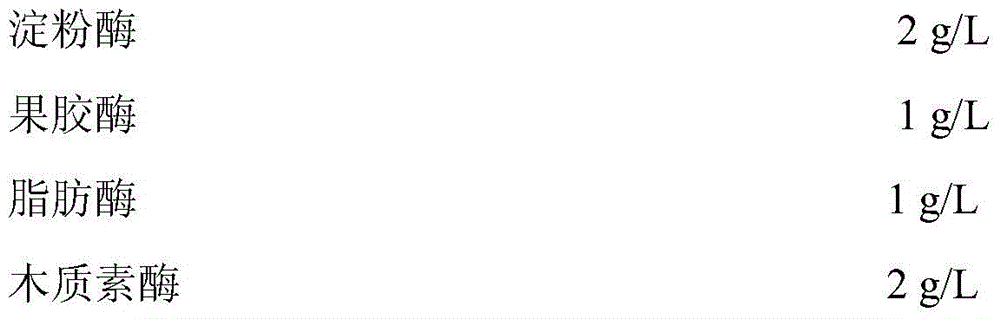

[0018] A one-bath low-temperature desizing, refining and bleaching pretreatment method for cotton woven fabrics, the process is as follows: Add amylase, pectinase, lipase, ligninase, hydrogen peroxide, acyloxy group to the one-bath pretreatment system A new type of bleach activator (Shangyu Jiehua Chemical Co., Ltd., the structural formula is Auxiliaries and chelating agents, adjust the pH to 7 with acetic acid, put the fabric (pure cotton woven gray fabric, the size used is starch slurry) into the pretreatment solution at a bath ratio of 1:50, and heat up at a heating rate of 2°C / min to 50°C, keep warm for 60 minutes, and finally wash and dry the fabric.

[0019] The one-bath processing prescription is as follows:

[0020]

[0021]

Embodiment 2

[0023] A one-bath low-temperature desizing, refining and bleaching pretreatment method for cotton woven fabrics, the process is as follows: Add amylase, pectinase, lipase, ligninase, hydrogen peroxide, acyloxy group to the one-bath pretreatment system Novel bleach activator (structural formula is Auxiliaries and chelating agents, adjust the pH to 6 with hydrochloric acid, put the fabric (pure cotton woven gray fabric, the size used is starch slurry) into the pretreatment solution at a bath ratio of 1:20, and heat up at a heating rate of 2°C / min To 45 ℃, keep warm for 60min, finally wash the fabric and dry it.

[0024] The one-bath processing prescription is as follows:

[0025]

Embodiment 3

[0027] A one-bath low-temperature desizing, refining and bleaching pretreatment method for cotton woven fabrics, the process is as follows: add PVA enzyme, pectinase, lipase, ligninase, hydrogen peroxide, acyloxy group to the one-bath pretreatment system Novel bleach activator (structural formula is Penetrant SF and chelating agent, adjust the pH to 6 with sodium bicarbonate, put the fabric (pure cotton woven gray fabric, the slurry used is PVA slurry) into the pretreatment solution at a bath ratio of 1:50, at a rate of 2°C / min The heating rate was raised to 60°C, and the temperature was kept for 60 minutes. Finally, the fabric was washed and dried.

[0028] The one-bath processing prescription is as follows:

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com