Aluminum-silicon alloy for rheo-diecasting radiating shell and preparation method of aluminum-silicon alloy

An aluminum-silicon alloy and rheological die-casting technology, applied in the field of aluminum-silicon alloy and its preparation, can solve the problems of heat dissipation performance deviation, high thermal conductivity, and large weight of a heat dissipation shell, so as to ensure uniformity, meet fluidity requirements, The effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

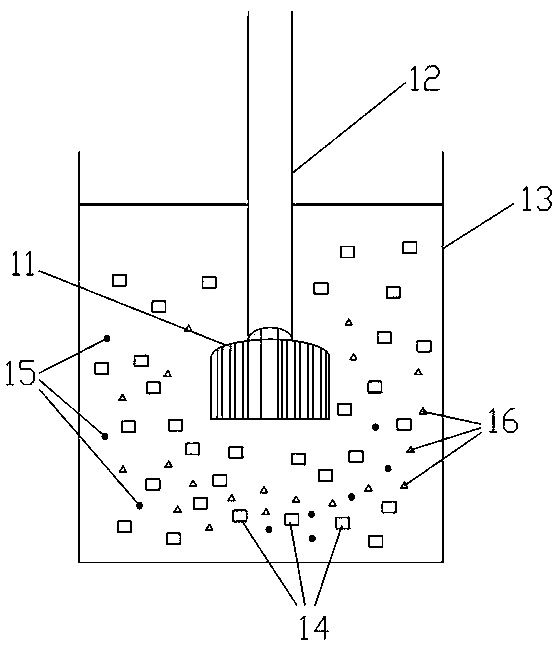

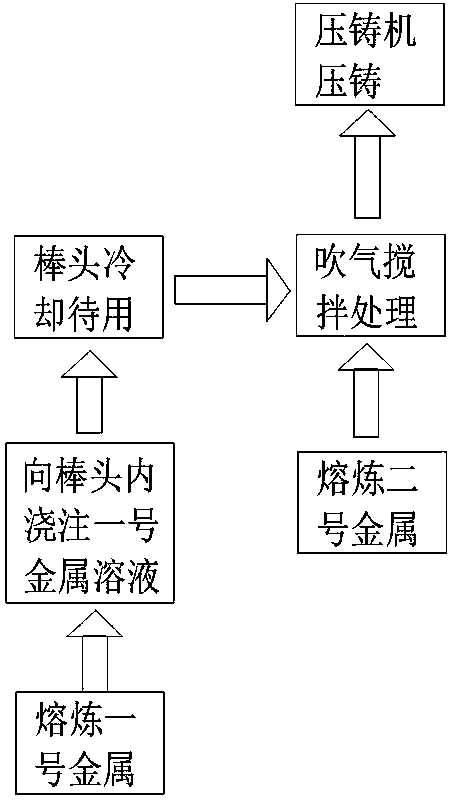

Method used

Image

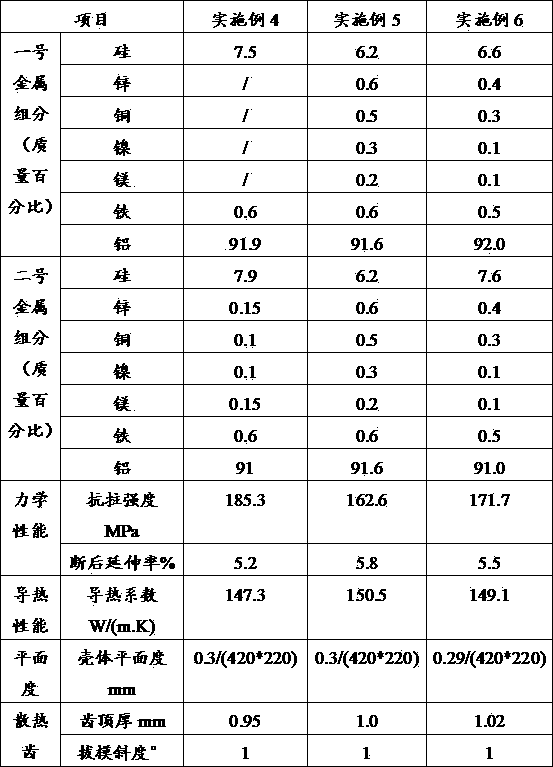

Examples

Embodiment 1

[0031] The technical solution adopted in the present invention is an aluminum-silicon alloy of a rheological die-casting heat dissipation housing. The mass percentages of each component in the aluminum-silicon alloy are: silicon 8.0%, copper 1.5%, zinc 2.0%, nickel 2.0%, magnesium 0.8% , iron 1.0%, the rest is aluminum and unavoidable trace impurities.

Embodiment 2

[0033] An aluminum-silicon alloy of a rheological die-casting heat dissipation shell, the mass percentage of each component in the aluminum-silicon alloy is: 5.5% silicon, 0.1% copper, 0.1% zinc, 0.1% nickel, 0.1% magnesium, 0.1% iron, and the rest Aluminum and unavoidable trace impurities.

Embodiment 3

[0035] An aluminum-silicon alloy of a rheological die-casting heat dissipation shell, the mass percentage of each component in the aluminum-silicon alloy is: silicon 6.5%, copper 0.8%, zinc 0.9%, nickel 0.8%, magnesium 0.4%, iron 0.5%, and the rest Aluminum and unavoidable trace impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com