Preparation method of conductive printing ink for gas sensor electrode material

A gas sensor and printing ink technology, applied in the field of printing electronic ink, can solve the problems of complex process and high cost, and achieve the effects of simple production process, low product cost and simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

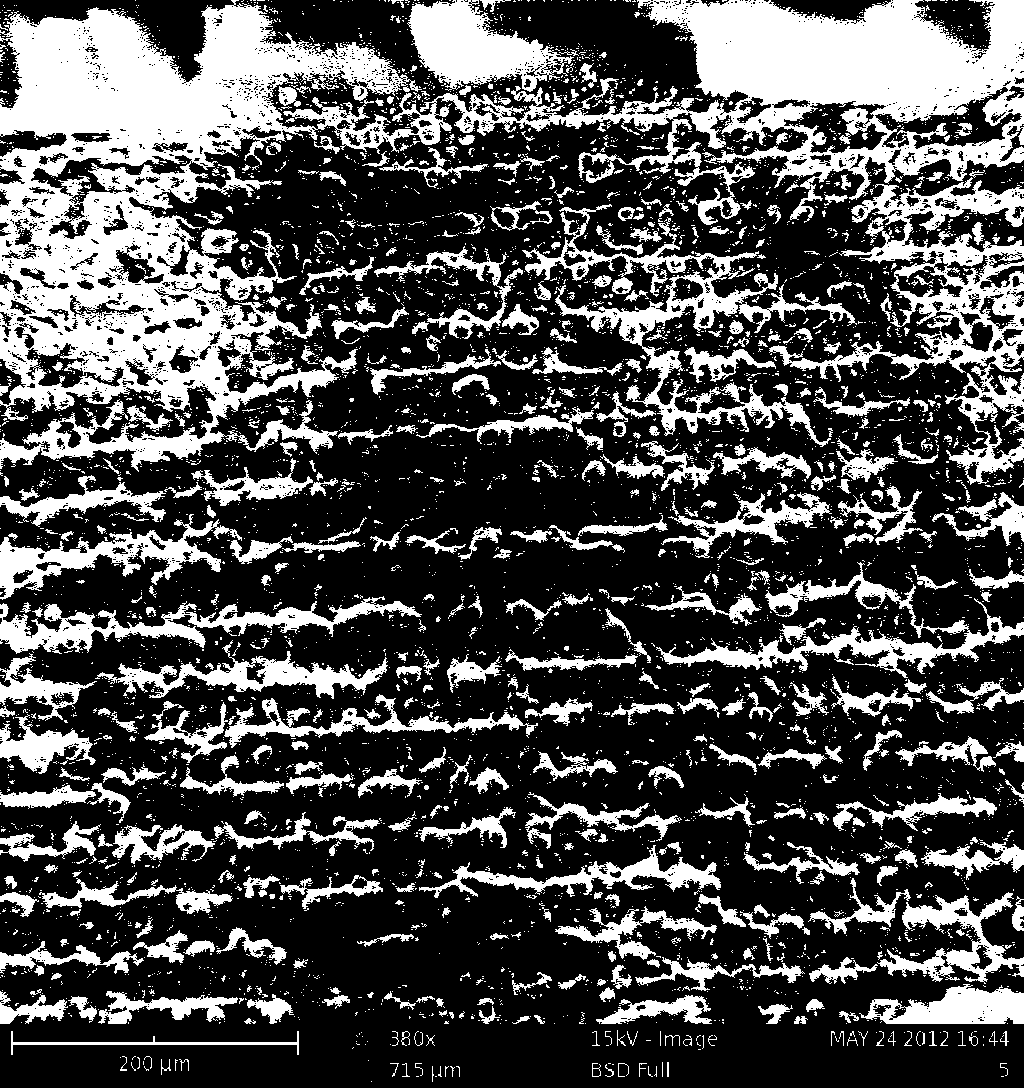

Image

Examples

Embodiment 1

[0034] Dissolve 2.4g of PVA in 5ml of boiling water for activation and place it in a 1L three-neck flask, adjust the pH to 8~9 with 0.1% NaOH solution. Mix 110g of formaldehyde and 110g of urea into the three-necked flask, react at 45°C for 5-8min, about Raise the temperature to 75°C in 30 minutes, keep the temperature for 30 minutes, and adjust the pH value between 7 and 8 with 1% sodium hydroxide solution. Then add 37g of urea, lower the temperature to 70°C, and adjust the pH to 5~6 with 1% NaOH solution. Stop heating after 30 minutes of reaction, and keep warm for 30 minutes. Continue to add 10g of urea and 6.3g of melamine, and adjust the pH to 7~8 with 1% NaOH solution. After reacting for 30 minutes, the system was quickly cooled to below 40°C, and the modified urea-formaldehyde resin was obtained by discharging.

[0035] Mix 110g of formaldehyde and 110g of urea into a three-neck flask, react at 45°C for 5-8min, raise the temperature to 75°C in about 30min, and keep th...

Embodiment 2

[0038] Dissolve 2.4g of PVA in 5ml of boiling water for activation and place it in a 1L three-neck flask, adjust the pH to 8~9 with 0.1% NaOH solution. Mix 110g of formaldehyde and 110g of urea into the three-necked flask, react at 45°C for 5-8min, about The temperature was raised to 75°C in 30 minutes, the pH value was adjusted between 7 and 8 with 1% sodium hydroxide solution, and the temperature was kept constant for 30 minutes. Then add 37g of urea, lower the temperature to 70°C, and adjust the pH to 5~6 with 1% NaOH solution. Stop heating after 30 minutes of reaction, and keep warm for 30 minutes. Continue to add 10g of urea and 6.3g of melamine, and adjust the pH to 7~8 with 1% NaOH solution. After reacting for 30 minutes, the system was quickly cooled to below 40°C, and the modified urea-formaldehyde resin was obtained by discharging.

[0039] Mix 110g of formaldehyde and 110g of urea into a three-neck flask, react at 45°C for 5-8min, raise the temperature to 75°C in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com