Method for modifying packing, alpha-cristobalite powder, used for polymer material

A technology of polymer materials and cristobalite powder, which is applied in the field of filler modification for polymer materials, can solve the problems of reducing the tensile strength, impact strength, and inability to disperse uniformly of polymer composite materials, and achieve good lipophilicity and improved Sexual Effects Good Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

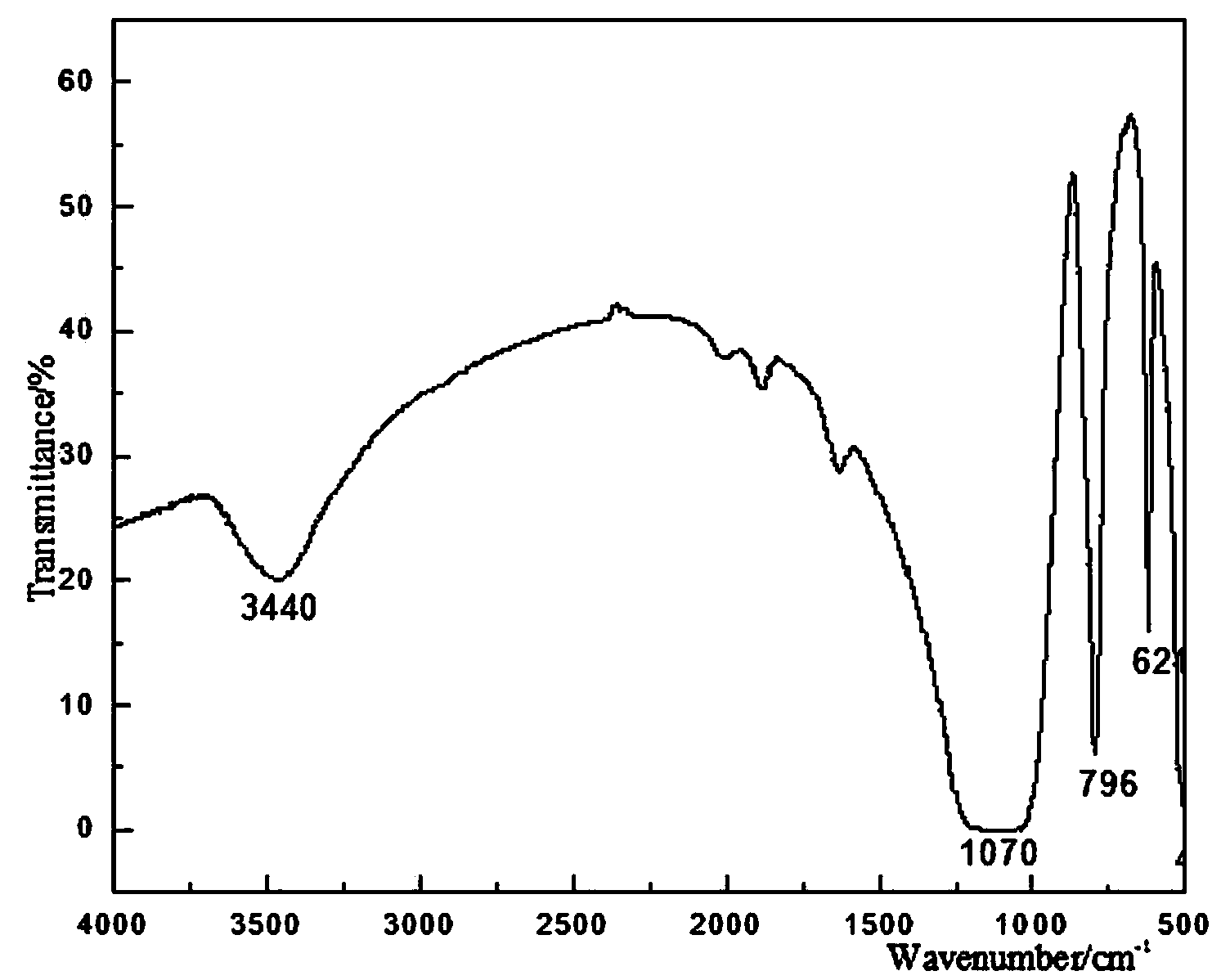

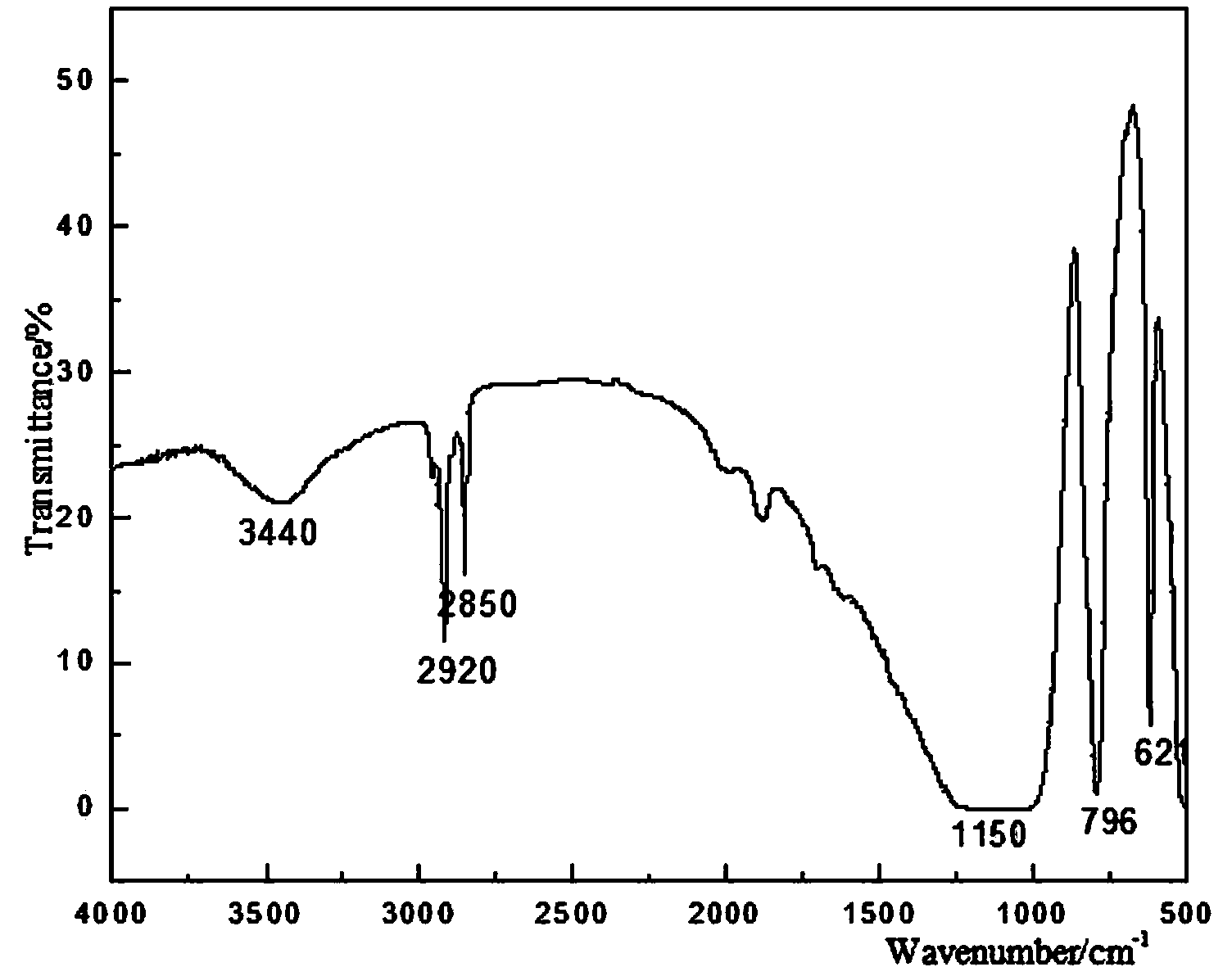

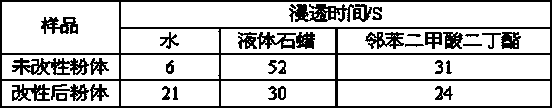

Method used

Image

Examples

Embodiment 1

[0021] A method for modifying filler α-cristobalite powder used in polymer materials, wherein: the activator used is aluminate coupling agent (DL-411A), and the specific steps are as follows:

[0022] Step 1: Dissolve the aluminate coupling agent with a solvent at room temperature, put it into a round bottom flask, and put it into an ultrasonic cleaner to accelerate the dissolution of the aluminate coupling agent in the solvent for 8 minutes to 10 minutes;

[0023] Step 2: Put the self-made α-cristobalite powder into the prepared aluminate coupling agent solution, disperse it ultrasonically for 28 min to 30 min, make the reactant thick, put it into the electric heating mantle and heat it at 110°C Under heating for 8 hours, take out the powder obtained after the reaction.

[0024] Described solvent is toluene.

[0025] The mass percent content of the aluminate coupling agent is 3.8%.

[0026] The aluminate coupling agent solution in the step 2 is recovered with a condenser. ...

Embodiment 2

[0048] Compared with Example 1, other conditions remain unchanged, the solvent used is absolute ethanol, and the activation index of α-cristobalite powder is 31.5%.

Embodiment 3

[0050] Compared with Example 1, other conditions remain unchanged, the solvent used is DMF, and the activation index of α-cristobalite powder is 45.6%.

[0051] Composite materials were prepared by using modified α-cristobalite powder and PVC resin. Its processing performance, mechanical properties and thermal stability were detected, and it was found that when the amount of modified α-cristobalite filler was 10%, the rheological performance and thermal stability were the highest, and the processing difficulty was the lowest. According to the SEM picture of the cross-section of the material, it is found that the dispersion of the filler in the PVC resin is the best, and the interface bonding effect with the PVC matrix is the best, so that the tensile strength and impact strength of the composite material are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com