Method for modifying carbon fiber composite material by cryogenic treatment

A technology of cryogenic treatment and composite materials, applied in the field of modification of high-performance fiber composite materials, to achieve the effects of enhanced adhesion, convenient operation, and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

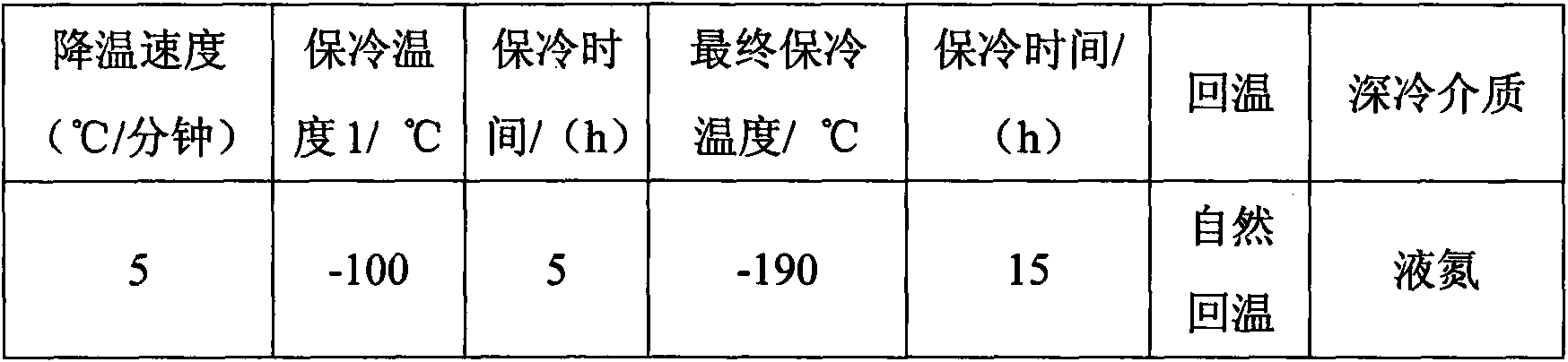

Embodiment 1

[0029] A method for modifying carbon fiber composite material by cryogenic treatment, the carbon fiber composite material is a carbon fiber (T300) non-woven felt reinforced unsaturated polyester resin composite material, which includes a matrix resin and is used as a reinforcement in the matrix resin The carbon fiber of the body, the volume ratio of the matrix resin and carbon fiber is 50:50, the matrix resin is unsaturated polyester, and the carbon fiber is T300, which is set in the matrix resin in the form of a two-dimensional non-woven fabric. The carbon fiber composite material is self-prepared, the carbon fiber is T300 fiber, the length is 3 cm to 6 cm, and the diameter of fiber filament is 6 microns; fabric structure: needle-punched non-woven felt; unsaturated polyester resin grade: 901-VP.

[0030] The preparation method adopts the vacuum-assisted resin transfer molding method. The preparation method adopts the vacuum-assisted resin transfer molding method. The specific ...

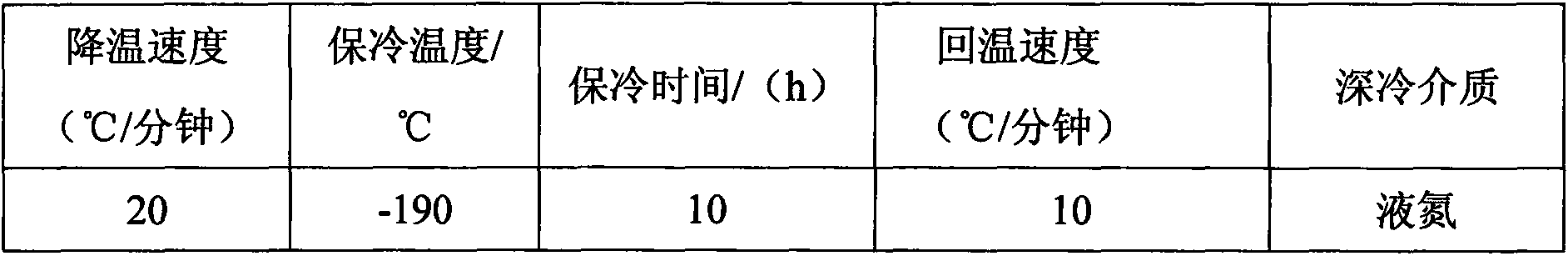

Embodiment 2

[0036] A method for modifying carbon fiber composite material by cryogenic treatment, the carbon fiber composite material is a two-dimensional carbon fiber (T300) woven fabric reinforced epoxy resin composite material, which includes a matrix resin and a reinforcement set in the matrix resin as a reinforcement Carbon fiber, the weight ratio of the matrix resin to carbon fiber is 55:45, the matrix resin is epoxy resin, and the carbon fiber is T300, which is arranged in the matrix resin in the form of carbon fiber two-dimensional fabric. The carbon fiber composite material is self-prepared, carbon fiber fabric parameters: T300 fibers with warp and weft yarn specifications of 12K, warp and weft density of 5 threads / cm, fabric structure: two-dimensional plain weave fabric; epoxy resin grade: JL-235. The preparation method adopts the vacuum-assisted resin transfer molding method, and the specific steps are the same as in Example 1. Composite material sample size is: length 30 cm, w...

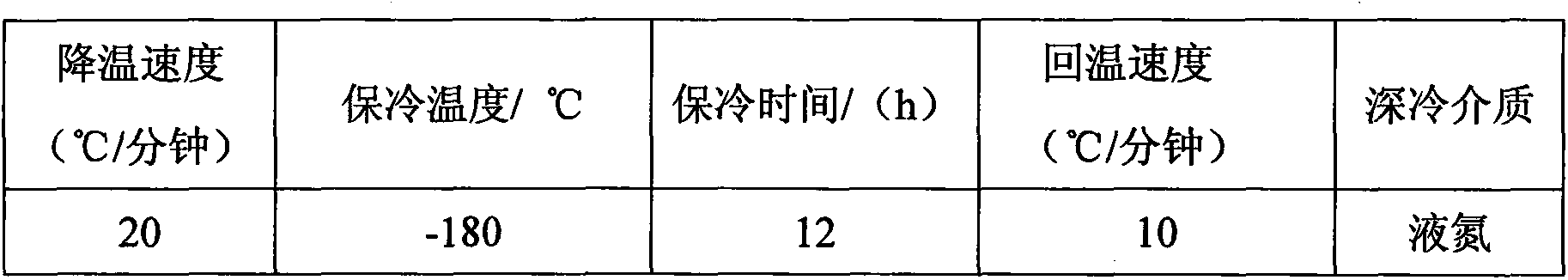

Embodiment 3

[0042] A method for modifying carbon fiber composite material by cryogenic treatment, the carbon fiber composite material is a two-dimensional carbon fiber (T700) woven fabric reinforced epoxy resin composite material, which includes a matrix resin and a matrix resin used as a reinforcement For carbon fiber, the volume ratio of the matrix resin and carbon fiber is 55:45. The matrix resin is epoxy resin, and the carbon fiber is T700, which is set in the matrix resin in the form of carbon fiber two-dimensional fabric. The carbon fiber composite material is self-prepared, carbon fiber fabric parameters: T700 fiber (model: T700SC-12000-50C) with warp and weft thickness of 12K, warp and weft density of 5 threads / cm, fabric structure: two-dimensional plain weave fabric; epoxy Resin grade: JL-235. The preparation method adopts the vacuum-assisted resin transfer molding method, and the specific steps are as described in Example 1. Composite material sample size is: length 30 cm, wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com