Compound flocculant taking natural minerals as main components

A mineral and flocculant technology, which is applied in the field of composite flocculant and its preparation, can solve the problems of limited use and poor water purification effect, and achieve the effects of strong cohesion, low moisture content of sludge, and shortened process residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

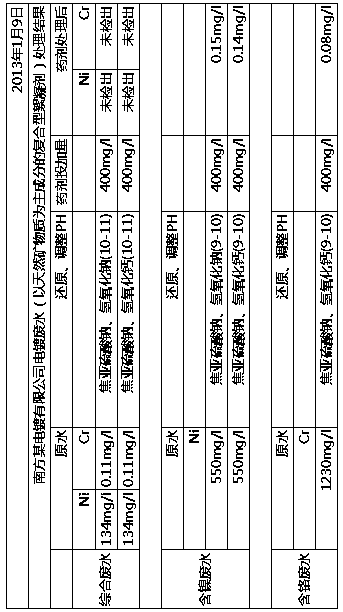

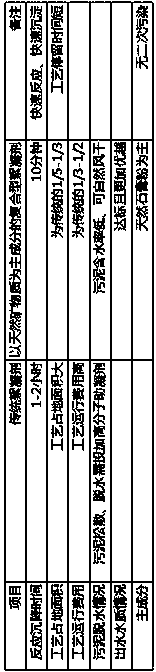

[0044] Application of composite flocculant mainly composed of natural minerals in electroplating wastewater treatment.

[0045] figure 1 : Electroplating wastewater test results

[0046] figure 2 : Comparison of traditional flocculant and the composite flocculant of the present invention with natural minerals as the main component

[0047] image 3 : beaker experiment

[0048] Project site pictures

[0049] Figure 4 : Raw water of electroplating wastewater

[0050] Figure 5 : Process debugging

[0051] Image 6 : Dry powder dosing machine

[0052] Figure 7 : Alum flower form

[0053] Figure 8 : water after treatment

[0054] In Example 1, 60-85% of natural minerals, 8-38% of traditional inorganic flocculants, 3-10% of organic polymer flocculants, preferably 60-85% of hemihydrate gypsum powder (wherein the content of hemihydrate gypsum is greater than or equal to 75% %, dihydrate gypsum is less than 5%, soluble anhydrite content is less than 5%), aluminum su...

Embodiment 2

[0056] Application of composite flocculant mainly composed of natural minerals in the treatment of printing and dyeing wastewater.

[0057] Figure 9 : Comparison before and after decolorization of cationic dye wastewater

[0058] Figure 10 : Contrast before and after decolorization treatment of reactive dye wastewater

[0059] Figure 11 : sludge form

[0060] In Example 2, 60-85% of natural minerals, 8-38% of traditional inorganic flocculants, and 3-10% of organic polymer flocculants. Preferably slaked lime 60-85%, magnesium sulfate (or ferrous sulfate) 8-38%, cationic polyacrylamide 3-10%.

Embodiment 3

[0062]Application of composite flocculant with natural minerals as main components in mine water treatment.

[0063] Figure 12 : mine water raw water

[0064] Figure 13 : Project installation and commissioning

[0065] Figure 14 : Alum flower form

[0066] Figure 15 : Raw water and treated effluent

[0067] Figure 16 : Mine water raw water test sheet

[0068] Figure 17 : Water test sheet after mine water treatment

[0069] In Example 3, 60-85% of natural minerals, 8-38% of traditional inorganic flocculants, and 3-10% of organic polymer flocculants. Preferable hemihydrate gypsum powder 60-85%, PAC (drum type) 8-38%, anionic polyacrylamide 3-10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com