A multi-station self-centering rotating fixture for bearing caps

A rotating fixture and self-centering technology, applied in the direction of manufacturing tools, clamping, support, etc., can solve the problems of difficulty in meeting the tolerance requirements of drawings, restricting the development of the industry, and low production efficiency, so as to meet the requirements of high symmetry and repeat positioning High precision and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

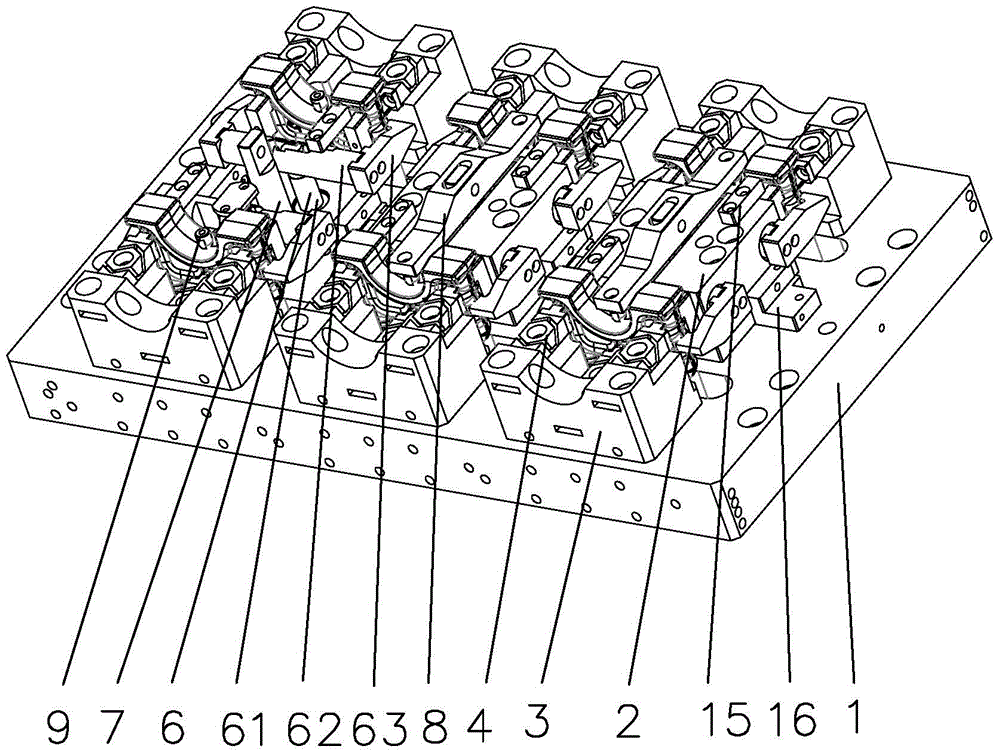

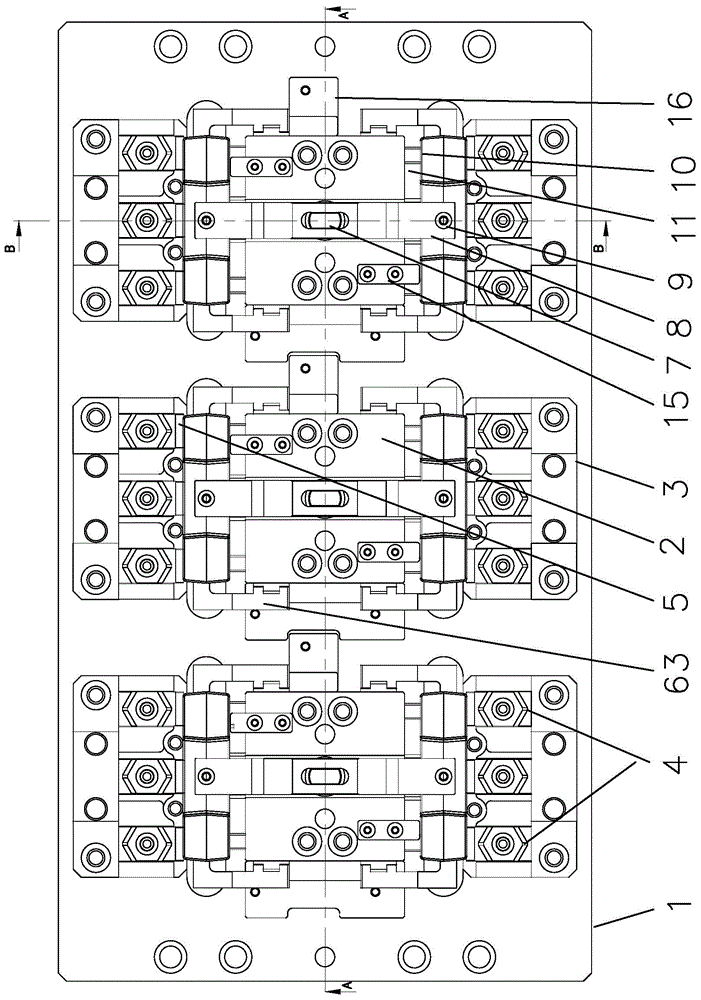

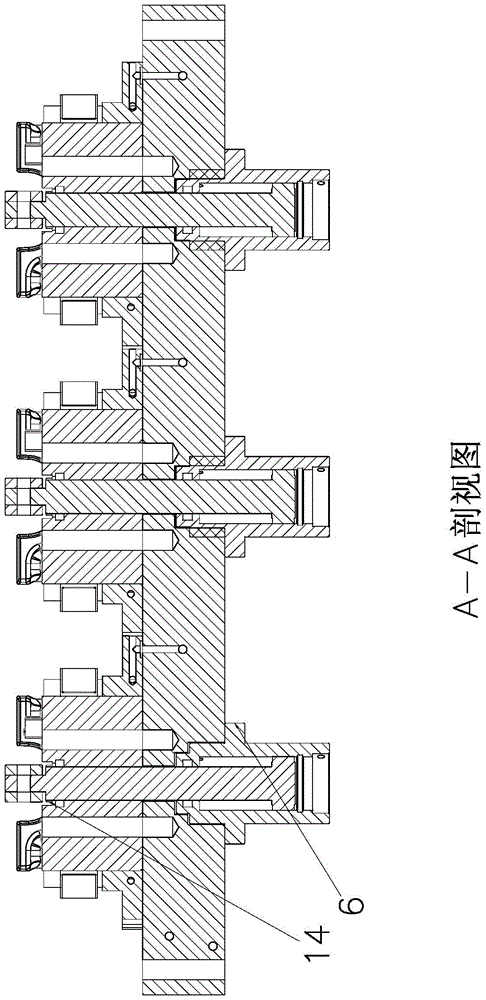

[0035] like Figure 1-Figure 4 As shown, a multi-station self-centering rotary fixture for a bearing cover includes a bridge plate 1, and three working units are arranged side by side on the bridge plate, and the working units successively include a first hydraulic main pressing mechanism, a first hydraulic pressure Self-centering mechanism, hydraulic auxiliary pressing mechanism, second hydraulic self-centering mechanism and second hydraulic main pressing mechanism;

[0036] The first hydraulic main pressing mechanism is the same as the second hydraulic main pressing mechanism, the first hydraulic self-centering mechanism is the same as the second hydraulic self-centering mechanism; the first hydraulic self-centering mechanism, the second hydraulic self-centering Both the centering mechanism and the hydraulic auxiliary pressing mechanism are arranged on the horizontal positioning plate 2 on the bridge plate.

[0037] The first hydraulic main pressing mechanism includes a cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com