A kind of absorbable fracture internal fixation material and its preparation method and application

A fixation material and an integrated technology, applied in fracture internal fixation materials, absorbable fracture internal fixation materials and their preparation, to achieve good biocompatibility, promote bone repair and healing, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

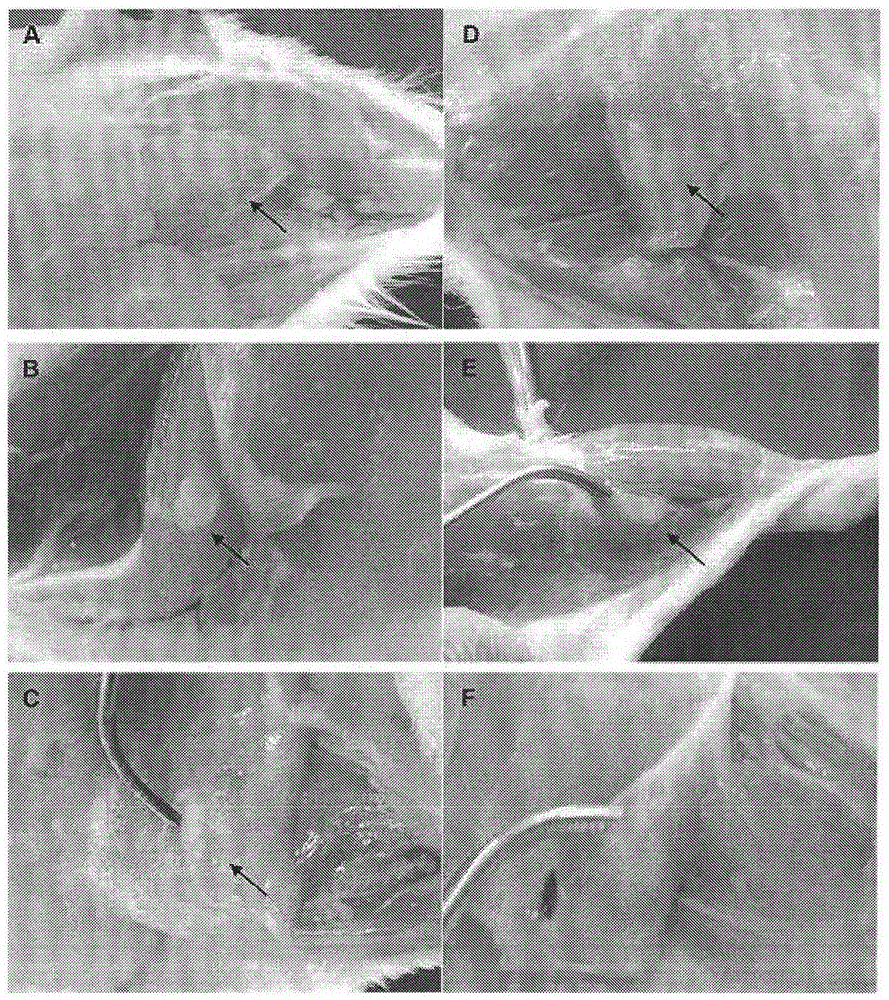

Image

Examples

Embodiment 1

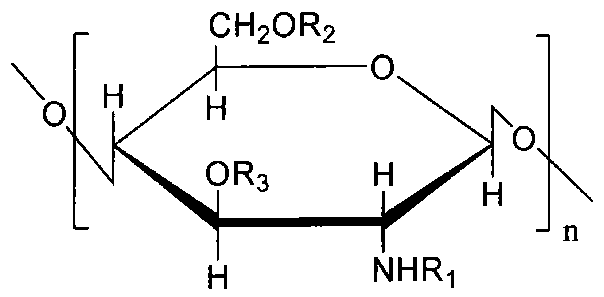

[0012] Embodiment 1 Preparation of acylated chitin plate 1:

[0013] Take by weighing chitosan powder 100g, add in glass reaction container, add acylating reagent acetic anhydride solution 300mL, add methanol 300ml, make the solid-liquid ratio (w / v, the same below) of reaction system be 1: 6, stir evenly, The reaction temperature was controlled at 0-5°C, 5ml of methanesulfonic acid solution was added as a catalyst, and the reaction was stirred for 48h. After the reaction is complete, filter, separate the solid from the liquid, wash the solid with water until neutral, separate the solid from the liquid, dehydrate with 95% aqueous ethanol (volume fraction, the same below), heat and dry at 50°C to obtain an acyl group with a degree of acetylation of 75%. Chitin powder.

[0014] Weigh 90g of acylated chitin powder with a degree of acetylation of 75%, put it into a glass container, add 400ml of formic acid aqueous solution with a solvent of 80% (concentration by weight, the same b...

Embodiment 2

[0015] Embodiment 2 Preparation of acylated chitin plate 2:

[0016] Weigh 50g of chitosan powder, add it to a glass reaction vessel, add 300mL of acylating reagent propionic anhydride solution, add 100ml of methanol, make the solid-liquid ratio of the reaction system 1:8, stir well, and control the reaction temperature at 20-25°C , 4ml of methanesulfonic acid solution was added as a catalyst, and the reaction was stirred for 48h. After the reaction is complete, filter, separate solid from liquid, wash the solid with water until neutral, separate solid from liquid, dehydrate with 95% aqueous ethanol, heat and dry at 50°C to obtain acylated chitin powder with a propionylation degree of 105%.

[0017] Weigh 30g of acylated chitin powder with a propionylation degree of 105%, put it into a glass container, add 1200ml of solvent hexafluoroisopropanol solution, stir and dissolve into a colloidal solution, add 1.5g of reinforcing agent regenerated cellulose fiber and disperse evenly ...

Embodiment 3

[0018] Embodiment 3 Preparation of acylated chitin plate 3:

[0019] Weigh 100g of chitin powder (85% degree of acetylation) with an acetyl content of 85%, add it to a glass reaction vessel, add 700mL of acylating reagent butyric anhydride solution, 100ml of butyric acid, and add 200ml of methanol to make the reaction system solid-liquid The ratio is 1:10, stir evenly, control the reaction temperature at 30-35°C, add 10ml of perchloric acid solution with a concentration of 80% by weight as a catalyst, and stir for 60h. After the reaction is completed, filter and separate the solid and liquid, neutralize the solid with 1mol / L NaOH, wash with water until the pH is neutral, separate the solid and liquid, dehydrate with 95% ethanol, and dry at 40°C to 50°C to obtain acylated Acylated chitin powder with a degree of 225%, wherein the degree of acetylation is 85%, and the degree of butyrylation is 140%.

[0020] Weigh 60g of the above-mentioned acylated chitin powder with a degree o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com