Preparation method and application of Mannich base corrosion inhibitor suitable for high temperature acidification

A Mannich base and corrosion inhibitor technology, which is applied in the field of Mannich base corrosion inhibitor preparation, can solve problems such as easy coking, corrosion inhibitor damage, corrosion inhibition effect decline, etc., to reduce production costs and improve surface activity , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

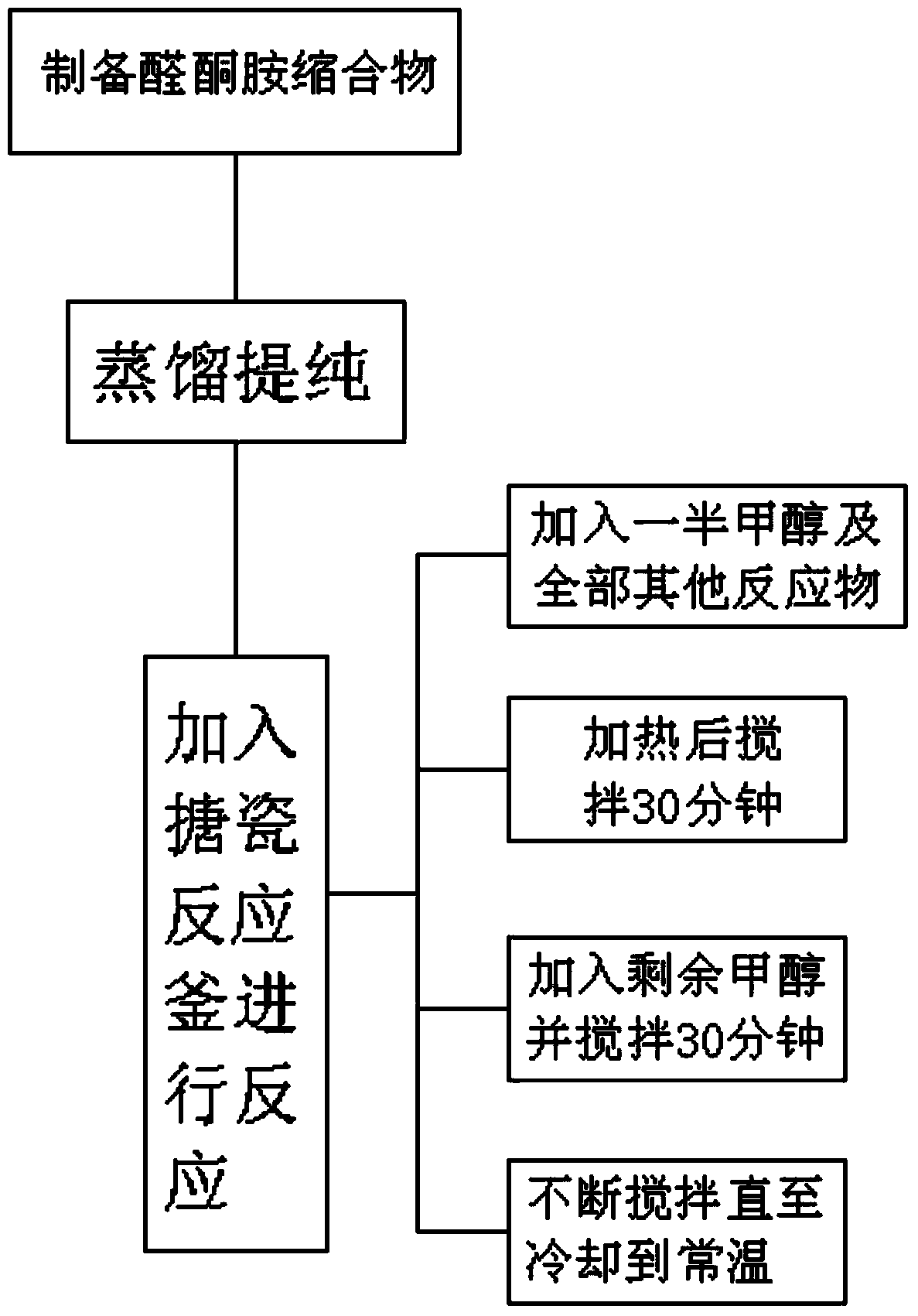

[0027] See attached figure 1 A method for preparing a Mannich base corrosion inhibitor suitable for high-temperature acidification provided by the invention comprises the following steps:

[0028] Step 1: Prepare aldehyde, ketone, and amine condensation products by Mannich base reaction; the composition of the reactant is as follows: calculated by the molar ratio of substances, 1 molar ratio of rosin amine, 2 to 4 molar ratios of paraformaldehyde, 2 to 3 Acetophenone and 2,4-pentanedione in molar ratio;

[0029] Step 2: Purifying the aldehyde, ketone, and amine condensate by vacuum distillation;

[0030] Step 3: Add the purified aldehyde, ketone, and amine condensates into a reaction vessel, and then add the following reactants to the reaction vessel under normal pressure: triethanolamine, 3-methyl-1-pentyn-3-ol, Pingpingjia O-25, Alkylphenol Polyoxyethylene Ether OP-10, Potassium Iodide, Methanol, Dimethylformamide and Bismuth Trichloride;

[0031] Wherein, the mass fracti...

Embodiment 1

[0038] Calculated according to the molar ratio of substances, add 2 molar ratios of paraformaldehyde, 2 molar ratios of acetophenone and 2,4-pentanedione into the enamel reaction kettle, slowly raise the temperature to 100°C, add hydrochloric acid as a catalyst for the reaction, hydrochloric acid Adjust the pH value of the reactant mixture to 3; then, add 1 mole ratio of rosin amine and methanol into the enamel reaction kettle, and react for 16 hours to form aldehyde, ketone and amine condensation products. Then, the aldehyde, ketone, and amine condensates generated are added to a distillation tower for purification by distillation under reduced pressure.

[0039] Add the purified aldehyde, ketone, and amine condensate into the enamel reaction kettle, control the pressure in the enamel reaction kettle to normal pressure, and then add the following reactants into the enamel reaction kettle: triethanolamine, 3-methyl-1-pentyne -3-alcohol, Pingpinga O-25, alkylphenol polyoxyethyl...

Embodiment 2

[0042] Calculated according to the molar ratio of substances, add 4 molar ratios of paraformaldehyde, 3 molar ratios of acetophenone and 2,4-pentanedione into the enamel reaction kettle, slowly raise the temperature to 110°C, add hydrochloric acid as a catalyst for the reaction, hydrochloric acid Adjust the pH value of the reactant mixture to 3; then, add 1 mole ratio of rosin amine and methanol into the enamel reaction kettle, and react for 16 hours to form aldehyde, ketone and amine condensation products. Then, the aldehyde, ketone, and amine condensates generated are added to a distillation tower for purification by distillation under reduced pressure.

[0043] Add the purified aldehyde, ketone, and amine condensate into the enamel reaction kettle, control the pressure in the enamel reaction kettle to normal pressure, and then add the following reactants into the enamel reaction kettle: triethanolamine, 3-methyl-1-pentyne -3-alcohol, Pingpinga O-25, alkylphenol polyoxyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com