Polymetalcarbosilane, and preparation method and application thereof

A carbosilane and metal technology, applied in the field of polymetallic carbosilane and its preparation, can solve the problems of long reaction process, long time consumption, harsh process conditions, etc., and achieve the effects of low preparation cost, simple reaction steps and high product conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

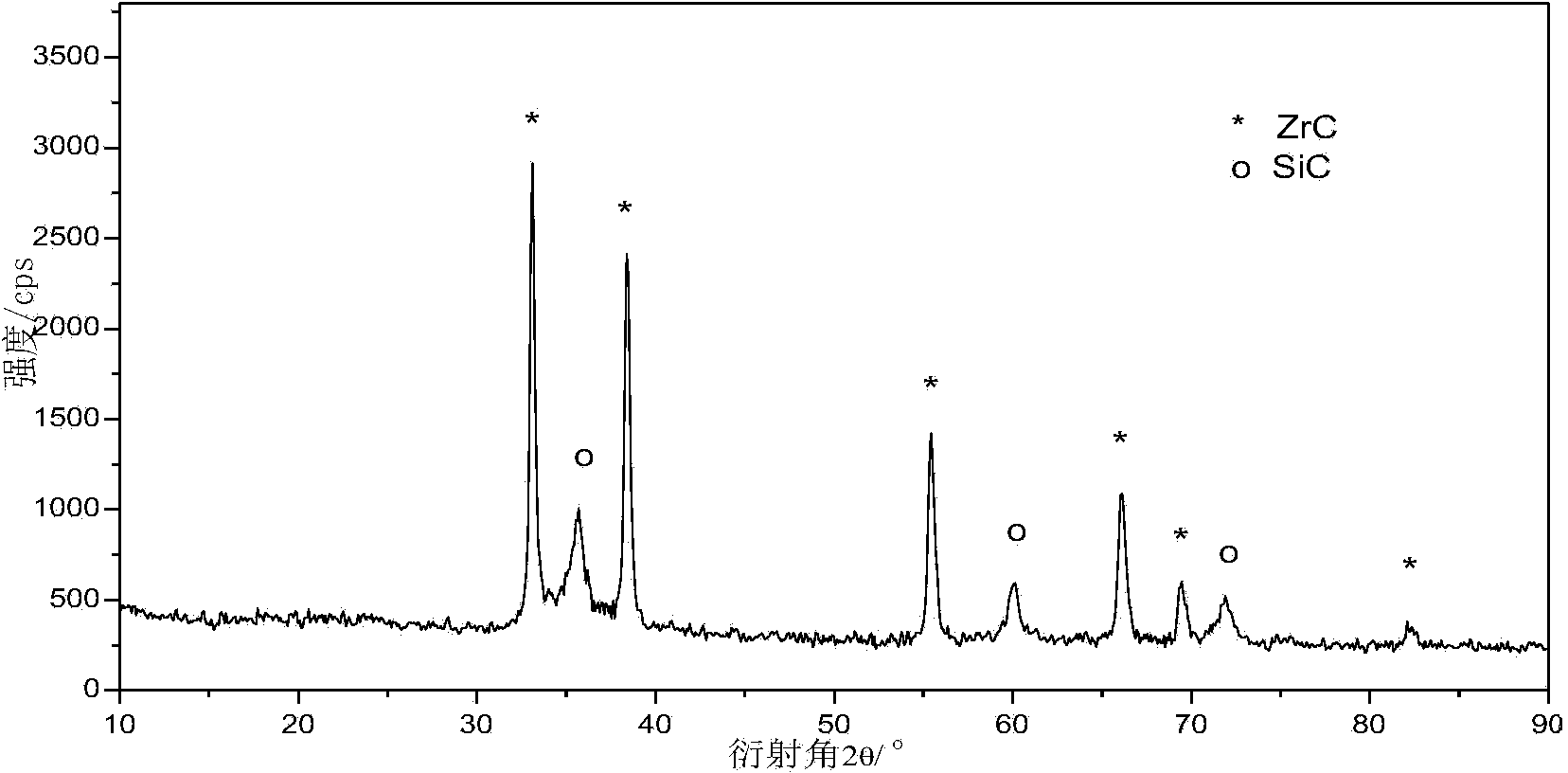

[0043] At room temperature and under the protection of nitrogen, add 12 grams of Na flakes and 250 mL of toluene into a 500 mL four-neck flask, stir at 110°C for 5 minutes at high speed to beat the sodium flakes into sodium sand, stop stirring, cool down to 100°C, and add 20.46 grams (0.07 mol) zirconocene dichloride, slowly drop in 27.10 g (0.21 mol) dichlorodimethylsilane, then stir for 5 hours under nitrogen protection and heating at 100°C until the solution is neutral, stop heating, and naturally cool to room temperature , to obtain solution G1. At -0.1MPa and 60°C, use a rotary evaporator to remove the toluene solvent in solution G1 to obtain 24.35 grams of dark brown viscous polymer, i.e. polyzirconium carbosilane A1, with a yield of 88.03wt% (based on the obtained polymetallic The theoretical yield of carbosilane is used as a basis for calculation).

[0044] Adopt KBr tablet method to carry out infrared spectroscopic analysis to solid product A1, the result is as follo...

Embodiment 2

[0049] At room temperature, under the protection of nitrogen, 12.88 grams of metal K and 150 mL of xylene were added to a 500 mL four-neck flask, and 4.38 grams (0.015 mol) of zirconocene dichloride was added under stirring conditions at 60°C, and 28.67 grams ( 0.15mol) of dichloromethylphenylsilane, then stirred at 60°C for 5 hours until the clear liquid was neutral, stopped heating, and naturally cooled to room temperature to obtain solution G2. The solvent in solution G2 was removed to obtain 20.24 g of a viscous polymer, namely polyzirconium carbosilane A2, with a yield of 87.13%.

[0050] Adopt KBr tabletting method to carry out infrared spectroscopic analysis to this viscous polymer A2, the result is as follows image 3 As shown, at wavenumber 1448cm -1 , wave number 1080cm -1 The absorption peak at corresponds to the absorption peak of cyclopentadienyl in zirconocene; at wavenumber 2091cm -1 place, wave number 879cm -1 The absorption peak at corresponds to the absor...

Embodiment 3

[0054] At room temperature and under the protection of nitrogen, 11.5 grams of Na and 280 mL of xylene were added to a 500 mL four-necked flask, and 2.49 grams (0.01 mol) of titanocene dichloride was added under stirring conditions at 110°C, and 25.81 grams (0.2 mol) dichlorodimethylsilane, and then stirred at 140° C. for 8 hours until the solution was neutral, then stopped heating, and naturally cooled to room temperature to obtain solution G3. The solvent in solution G3 was removed to obtain 10.2 g of a viscous polymer, namely polytitacarbosilane A3, with a yield of 76.23%.

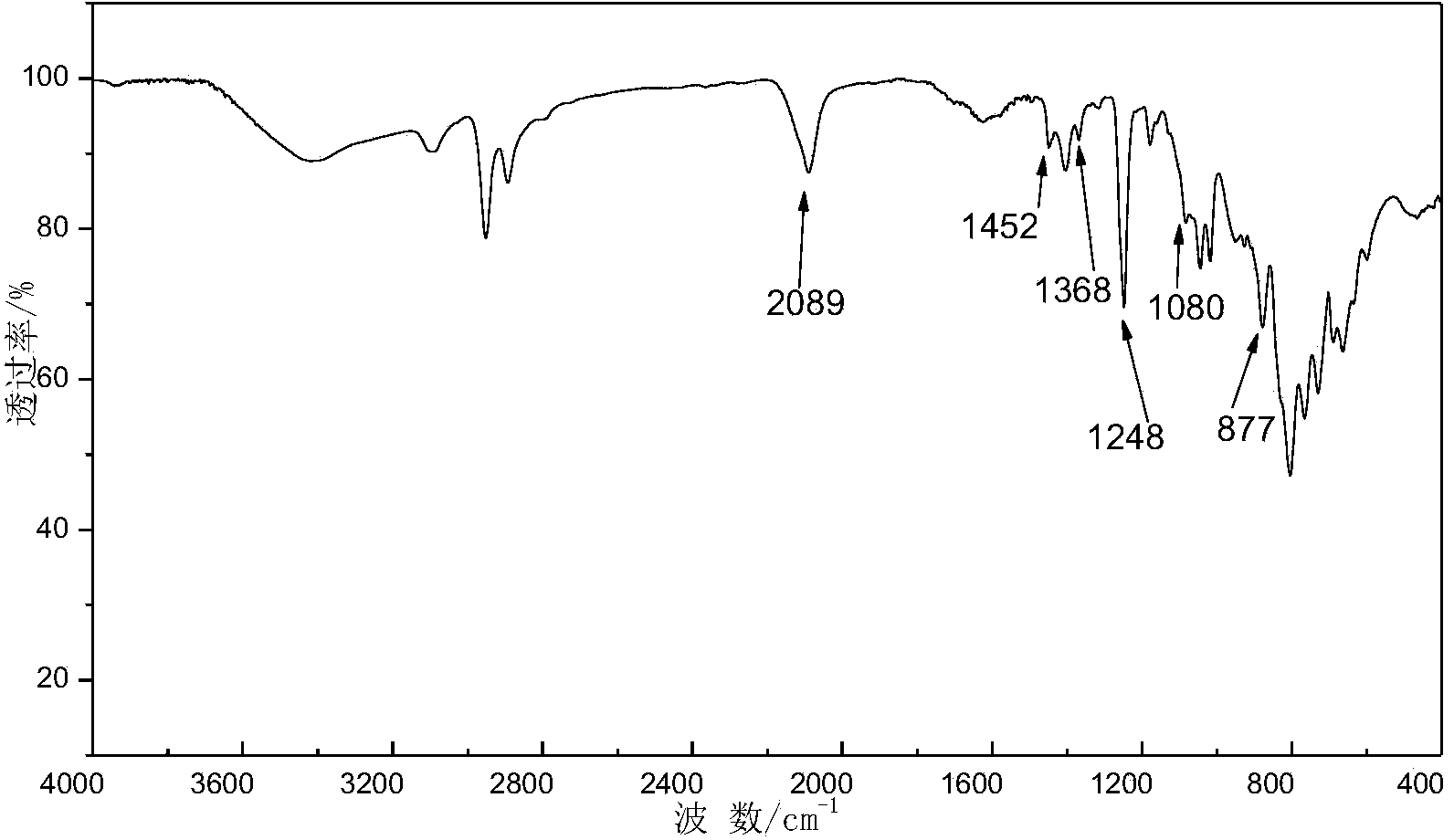

[0055] The solid product A3 was analyzed by infrared spectroscopy using the KBr tablet method, and the results showed that at wavenumber 1452cm -1 , wave number 1080cm -1 The absorption peak at corresponds to the absorption peak of cyclopentadienyl in zirconocene; at wave number 2089cm -1 place, wave number 877cm -1 The absorption peak at corresponds to the absorption peak of the Si-H bond; wavenumbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com