Rubber composite material of waste cotton material-based nano-microcrystalline cellulose and preparation method of rubber composite material

A nano-crystal and composite material technology, applied in the rubber field, can solve the problems of high energy consumption for mixing, long processing time, single color tone, etc., and achieves the effects of low cost, reduced reaction time, and simplified reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

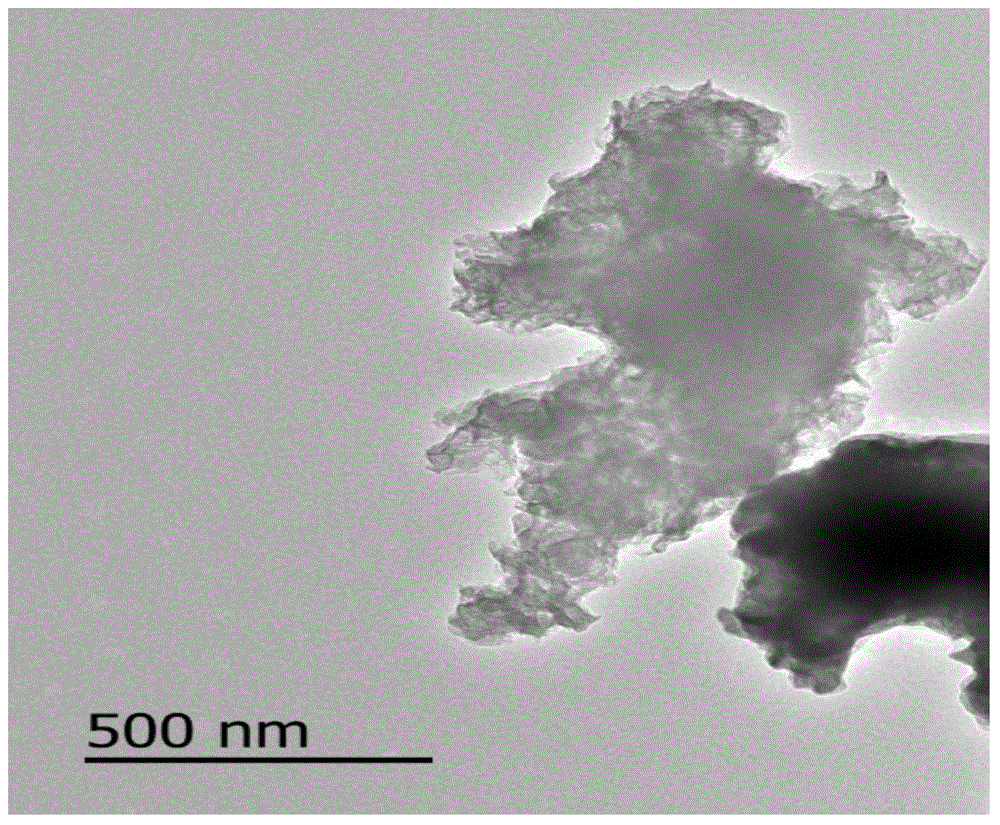

[0055] Waste cotton as a raw material was hydrolyzed by sulfuric acid with a mass fraction of 25% at 60°C for 180 minutes. The ratio of sulfuric acid to waste cotton is 16 (ml): 1 (g). After the reaction, centrifuge twice, neutralize, then centrifuge once, and ultrasonic for 10 minutes to obtain nanocrystalline cellulose with a diameter of 200-800nm. The length is 1 μm. Such as figure 1 and figure 2 shown.

Embodiment 2

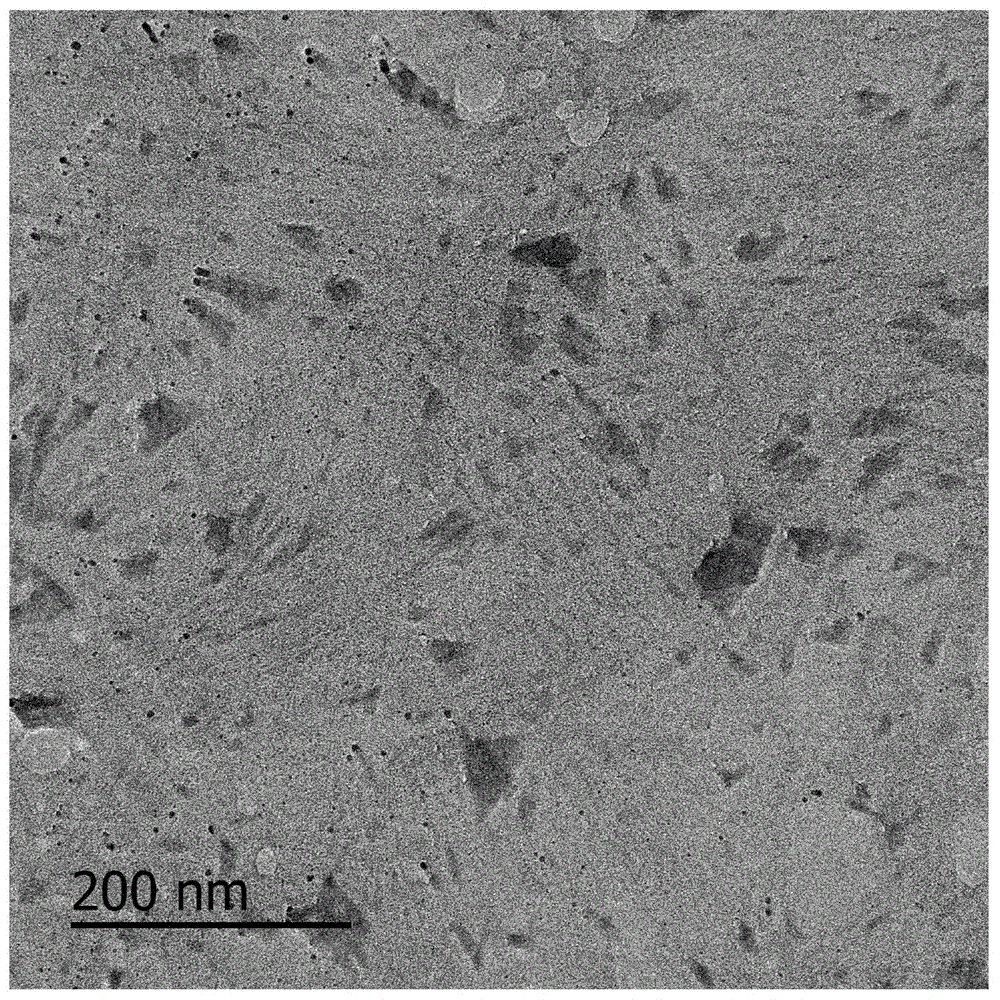

[0057] Waste cotton as a raw material was hydrolyzed by sulfuric acid with a mass fraction of 55% at 65° C. for 40 minutes. The ratio of sulfuric acid to waste cotton is 7 (ml): 1 (g). After the reaction, centrifuge twice, neutralize, centrifuge once more, and ultrasonicate for 10 minutes to obtain nanocrystalline cellulose with a diameter of 1-50nm. The particle length is 150nm, and the structure is a rod-shaped crystal product. Such as image 3 and Figure 4 shown.

[0058] The function of the sulfuric acid solution used in the present invention is to acidolyze the non-crystalline region (amorphous region) of the cellulose in the waste cotton, leaving the crystalline region, thereby preparing cotton nanocrystalline cellulose (CNC). This is because the structure of the non-crystalline region is loose, the bonding between molecules is not strong, the degree of order is not high, and it is easily affected by the acid hydrolysis of sulfuric acid molecules, while the structure...

Embodiment 3

[0060] The waste cotton is preliminarily screened and separated to remove impurities, and then crushed into short cotton. The crushed short cotton is added to a sulfuric acid solution with a mass fraction of 30% and stirred for 60 minutes. The reaction temperature is 80°C. The ratio of sulfuric acid to waste cotton is 15ml: 1g; after the reaction, centrifuge twice, adjust the pH to 6-7, centrifuge twice, and finally ultrasonicate for 20 minutes to obtain waste cotton nano-microcrystalline cellulose; the obtained product has a diameter of 1-100nm and a length of 10- 200nm, the structure is a rod-shaped crystal product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com