Preparation method of hyperbranched multifunctional dispersant

A dispersant, multi-functional technology, applied in the direction of pigment slurry, etc., can solve the problems of unsatisfactory particle stabilization effect, easy desorption, etc., and achieve the effect of storage stability and freeze-thaw stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

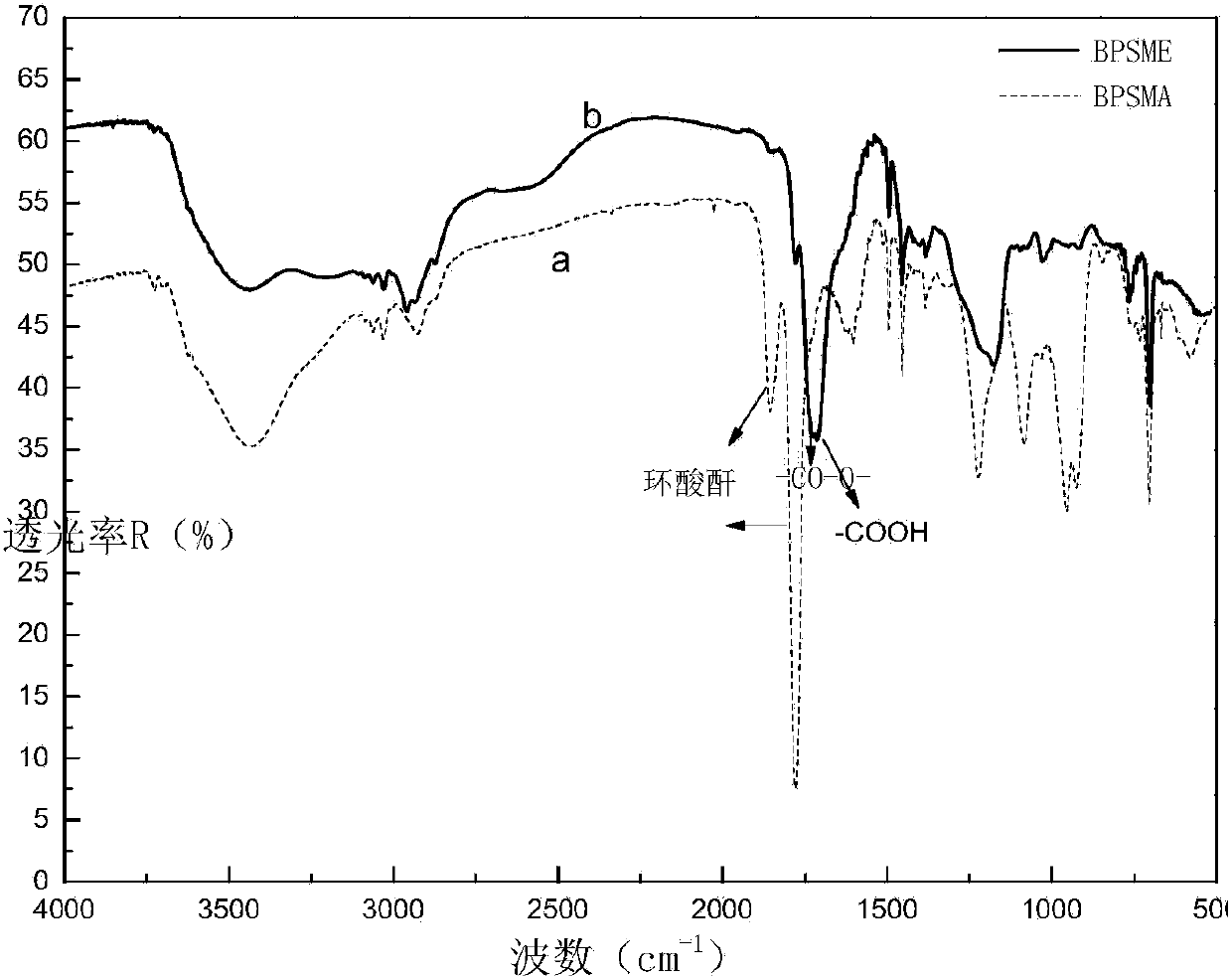

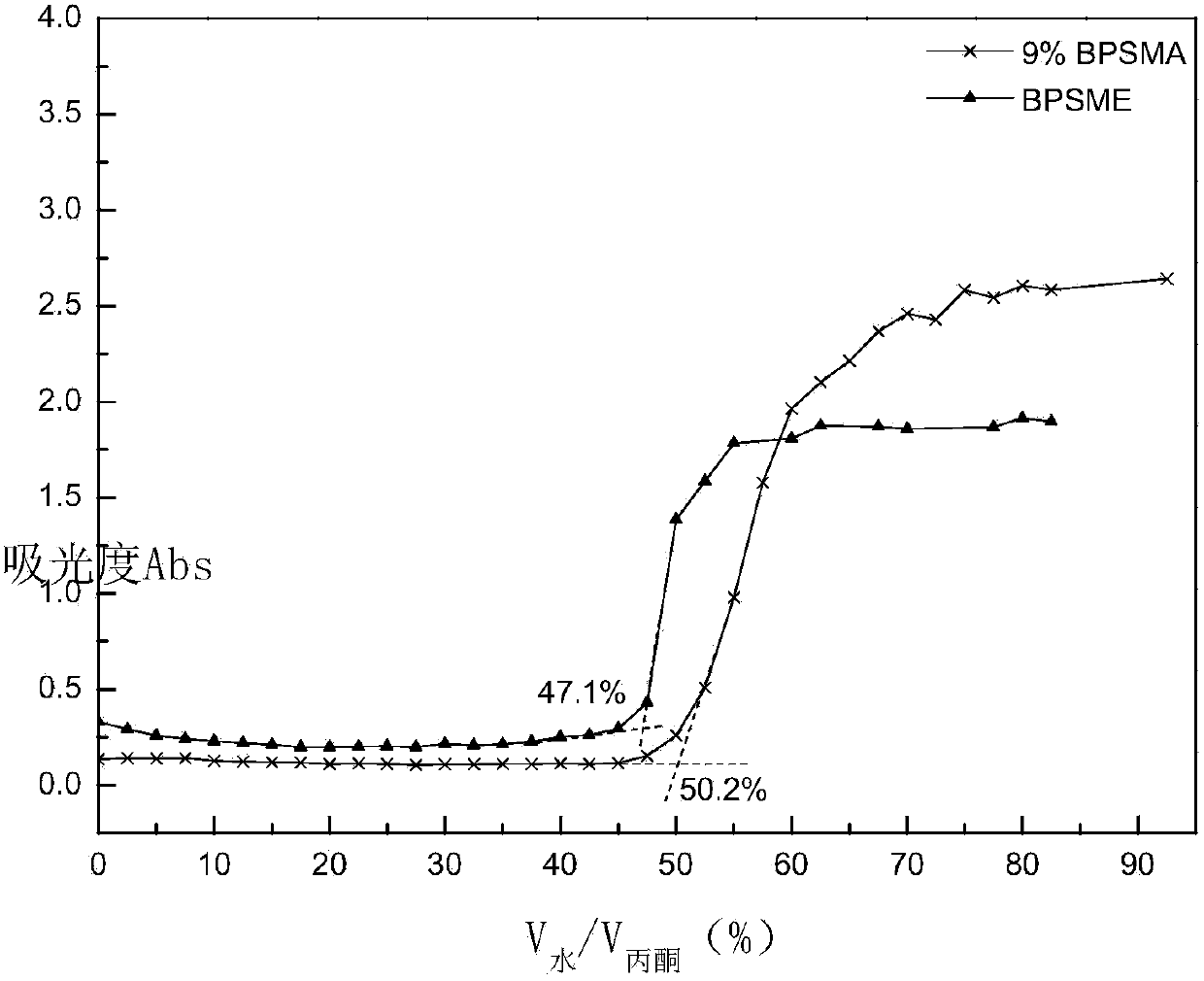

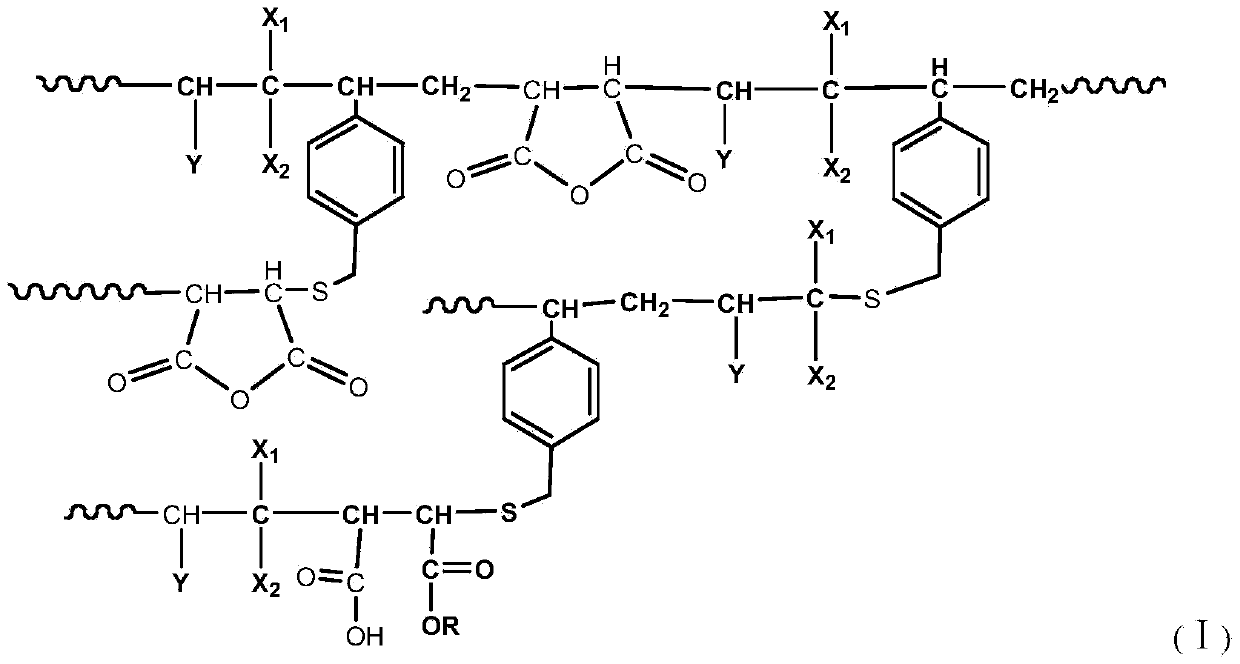

[0028] Dissolve monomer 0.98g maleic anhydride, 1.04g styrene and 0.10g p-vinylbenzyl mercaptan in a beaker containing 40g toluene, stir well until the solid is dissolved, then dissolve 0.23g azobisisobutyronitrile in the beaker Stir in a beaker with 20 g of toluene until the solids are completely dissolved. Add 1 / 3 of the mixed monomer solution and initiator solution to a 100ml four-necked flask with a condenser tube, stir and heat up to 65°C, and after 30 minutes of reaction, start adding the remaining monomer solution and initiator solution dropwise into the reaction solution. After the dropwise addition, the reaction was continued for 24 hours, and 0.2 g of p-toluenesulfonic acid and 1.6 g of methanol were added thereto, and the reaction was continued at 50° C. for 48 hours. After the reaction is completed, cool to room temperature, filter the obtained product with suction, wash with petroleum ether for 3 times, and then dry to obtain a hyperbranched solid dispersant (BPS...

Embodiment 2

[0031]Dissolve monomer 0.98g maleic anhydride, 2.00g methyl methacrylate and 0.30g vinyl benzyl mercaptan in a beaker containing 40g acetone, stir well until the solid dissolves, then add 0.25g azobisisoheptyl Dissolve the diester of nitrile azobisisobutyrate in a beaker containing 20 g of acetone and stir until the solid is completely dissolved. Add 1 / 3 of the mixed monomer solution and initiator solution to a 100ml four-neck flask with a condenser tube, stir and heat up to 70°C, and after 30 minutes of reaction, start adding the remaining monomer solution and initiator solution dropwise into the reaction solution. After the dropwise addition was completed, the reaction was continued for 6 h, and 0.2 g of triethylamine and 1.5 g of n-butanol were added thereto, and the reaction was continued at 80° C. for 8 h. After the reaction is completed, cool to room temperature, filter the obtained product with suction, wash with petroleum ether for 3 times, and then dry to obtain a hy...

Embodiment 3

[0034] Dissolve monomer 0.98g maleic anhydride, 0.86g methacrylic acid and 0.20g p-vinylbenzyl mercaptan in a beaker containing 40g cyclohexanone, stir until the solid dissolves, then add 0.24g benzyl peroxide Acyl was dissolved in a beaker with 20 g of cyclohexanone and stirred until the solid was completely dissolved. Add 1 / 3 of the mixed monomer solution and initiator solution to a 100ml four-neck flask with a condenser tube, stir and heat up to 90°C, after 30 minutes of reaction, start to drop the remaining monomer solution and initiator solution respectively into the reaction solution. After the dropwise addition, the reaction was continued for 2 h, and 0.12 g of 4-(dimethylamino)pyridine and 3.9 g of n-octanol were added thereto, and the reaction was continued at 90° C. for 24 h. After the reaction is completed, cool to room temperature, filter the obtained product with suction, wash with petroleum ether for 3 times, and then dry to obtain a hyperbranched solid dispersa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com