Micro water solid phase modifying method of gleditsia sinensis polysaccharide gum

A technology of polysaccharide gum and acacia, which is applied in the field of micro-water solid-phase modification of acacia polysaccharide gum, can solve the problems of few research reports on the modification of acacia polysaccharide gum, achieve simple and efficient modification process, reduce power consumption, and contact The effect of surface increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

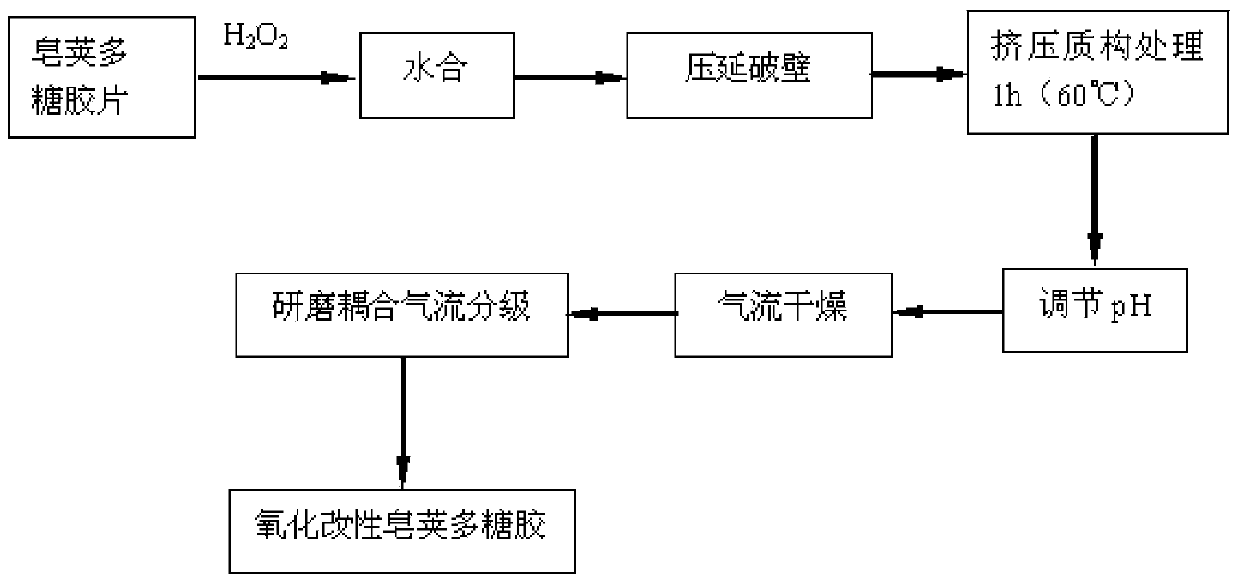

[0032] according to figure 1 As shown in the process flow chart, the saponins polysaccharide film is hydrated with an aqueous hydrogen peroxide solution with a pH of 11 (the concentration of hydrogen peroxide in water is 3%), and the mass ratio of solid to liquid is 1:1. After hydration for 15 minutes, the fully swollen film was calendered on a three-roll machine to form broken flakes into snowflakes, and then subjected to extrusion texture treatment in a screw extrusion reactor for 1 hour at a temperature of 60°C. After the reaction, spray and add 10% hydrochloric acid solution to adjust the pH value to neutral, then carry out air-drying, grinding and pulverizing coupled with air-flow classification, and obtain the modified product of acacia polysaccharide gum passing through a 120-mesh sieve. The measured molecular weight of the modified product is 1.92 million, the carboxyl substitution degree is 0.07, and the water-insoluble content is 8.7%.

Embodiment 2

[0034] according to figure 1 As shown in the process flow chart, the saponins polysaccharide film is hydrated with an aqueous hydrogen peroxide solution with a pH of 11 (the concentration of hydrogen peroxide in water is 10%), and the mass ratio of solid to liquid is 1:1. After hydration for 15 minutes, the fully swollen film was calendered on a three-roll machine to form broken flakes into snowflakes, and then subjected to extrusion texture treatment in a screw extrusion reactor for 1 hour at a temperature of 60°C. After the reaction, spray and add 10% hydrochloric acid solution to adjust the pH value to neutral, then carry out air-drying, grinding and pulverizing coupled with air-flow classification, and obtain the modified product of acacia polysaccharide gum passing through a 120-mesh sieve. The measured molecular weight of the modified product is 89,000, the carboxyl substitution degree is 0.45, and the water-insoluble content is 8.5%.

Embodiment 3

[0037] according to figure 1 As shown in the process flow chart, the saponins polysaccharide film is hydrated with an aqueous hydrogen peroxide solution with a pH of 11 (the concentration of hydrogen peroxide in water is 15%), and the mass ratio of solid to liquid is 1:1. After hydration for 15 minutes, the fully swollen film was calendered on a three-roll machine to form broken flakes into snowflakes, and then subjected to extrusion texture treatment in a screw extrusion reactor for 1 hour at a temperature of 60°C. After the reaction, spray and add 10% hydrochloric acid solution to adjust the pH value to neutral, then carry out air-drying, grinding and pulverizing coupled with air-flow classification, and obtain the modified product of acacia polysaccharide gum passing through a 120-mesh sieve. The measured molecular weight of the modified product is 70,000, the carboxyl substitution degree is 0.54, and the water-insoluble content is 8.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com