Plasma water treatment device

A water treatment device and plasma technology, which are applied in illumination water/sewage treatment, electrochemical water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problem that oxidation cannot be fully utilized and water treatment efficiency Low, complex structure and other problems, to achieve the effect of good water treatment, convenient operation, simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

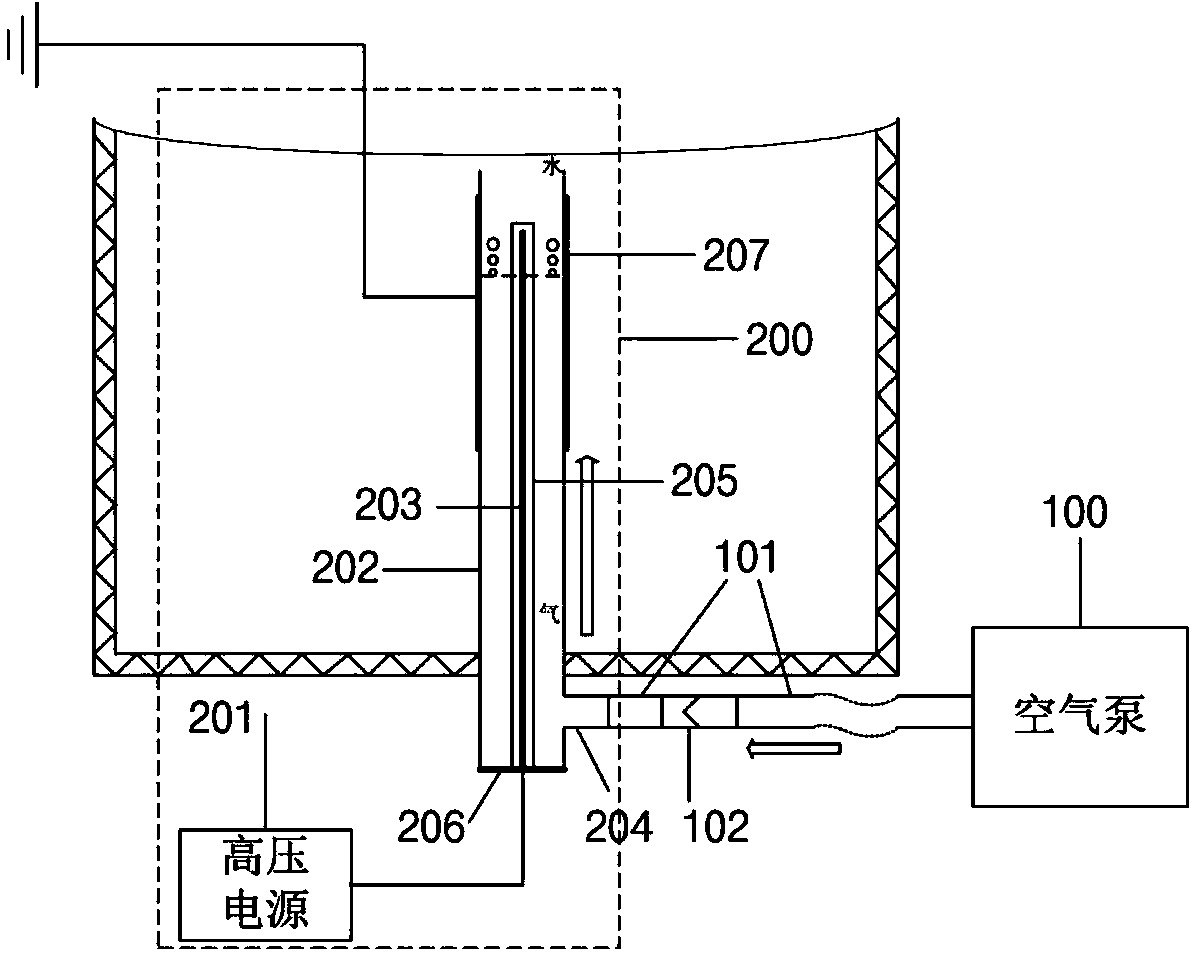

[0022] see figure 2 , the air purification device in this embodiment includes an air supply unit 100 and a plasma generator 200 .

[0023] The air supply unit 100 may include an air pump, a plastic conduit 101 and a one-way valve 102 . The air pump can pass outside air into the device to generate an air flow; the air flow flows into the plastic conduit 101 . In order to improve the quality of the incoming air, an air filter pipe can be arranged in the air pump to filter and purify the outside air first. The plastic conduit 101 can be designed to be very long as required, and a one-way valve 102 is arranged near its outlet. The one-way valve 102 ensures that water will not pour into the air pump when it is not working. Air is passed into the plastic conduit, through the one-way valve, and into the plasma generator 200 .

[0024] The air flow rate of the air pump 100 in the embodiment of the present invention is adjustable. By adjusting the air flow rate of the air pump 100,...

Embodiment 2

[0039] In this implementation, a plurality of uniformly spaced high-voltage electrodes are used to generate a dielectric barrier discharge ( image 3 Only three electrodes on the plane are shown in the figure, in fact, more electrodes can be used to make a three-dimensional matrix type large-scale discharge device), a glass cover 203 is still arranged outside each electrode, and a shell 202 is outside the glass cover, and all The shells are all grounded; and each electrode and the tail of each glass cover are airtightly connected to the circuit board 208. There is a conductive plate inside the circuit board 208. The upper part of the conductive plate is connected to all high-voltage electrodes 203, and the lower part is connected to the high-voltage wire 207. The high-voltage wire 207 Hard thick copper wire is selected, and the outside of the circuit board 208 and the high-voltage wire 207 are all made of rubber insulating material to ensure that high-voltage electricity is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com