Conductive paste for die bonding, and die bonding method using conductive paste for die bonding

A chip bonding and conductivity technology, applied in the field of conductive paste, can solve problems such as increased thermal stress, changes in the electrical characteristics of semiconductor chips, and the influence of semiconductor chip characteristics, and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

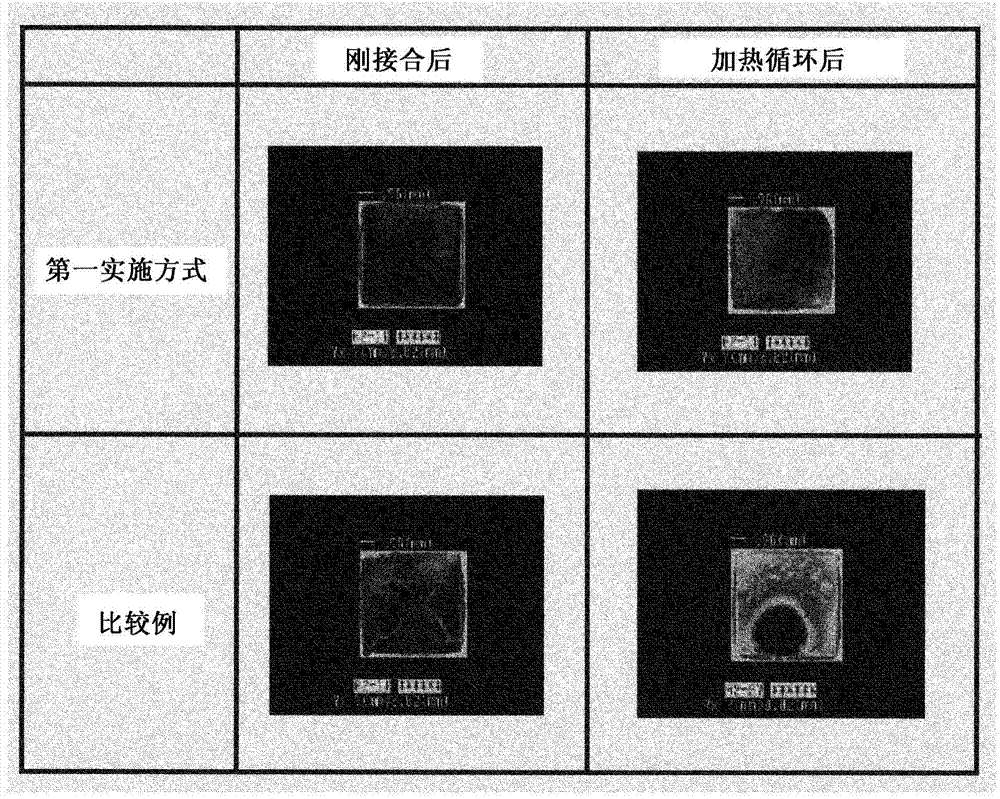

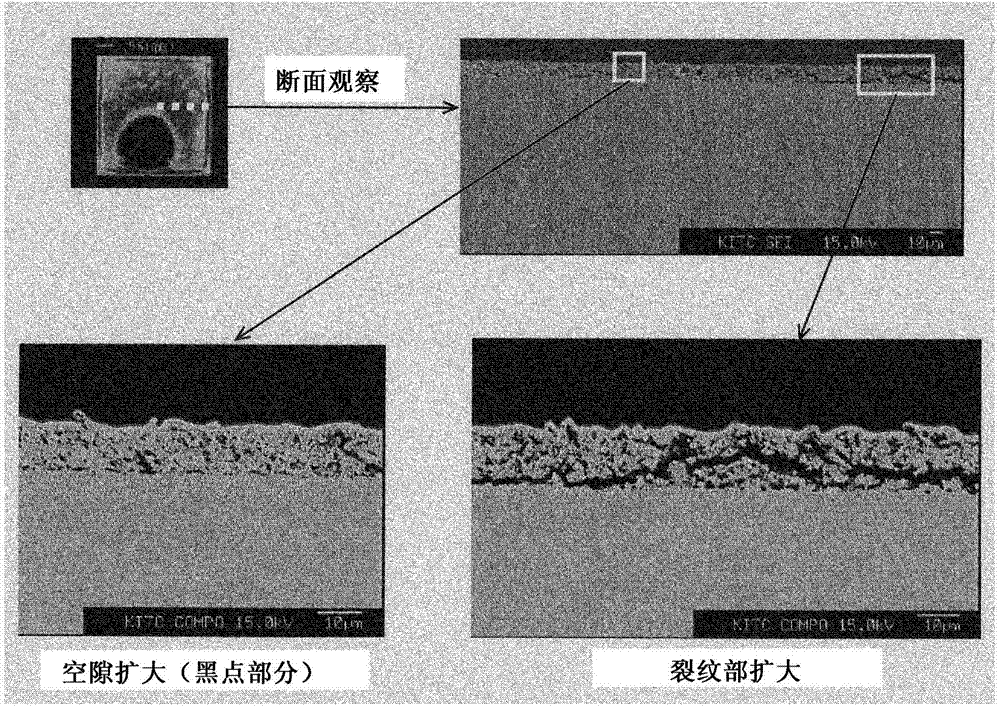

[0037] Here, a conductive paste obtained by dispersing a metal powder in which a coating layer made of gold is formed on a metal particle is produced, and the Si chip is die-bonded on a semiconductor substrate using the conductive paste. completeness research.

[0038] Manufacture of conductive paste :

[0039] Silver powder with a purity of 99.9% by mass (average particle diameter: 0.3 μm) produced by a wet reduction method was coated with gold as a coating layer. The formation of the coating layer is performed by an electroless plating method. Specifically, a non-cyanide displacement type electroless gold plating solution was used as the plating solution. As the gold source, a plating solution containing 5 g / L of gold sulfite was used as the gold concentration. As a pretreatment, use dilute sulfuric acid to remove oxides and sulfides on the surface of the silver powder. As the plating conditions, set the plating temperature to 70°C, put the silver powder into the platin...

no. 2 approach

[0055] Here, two kinds of metal powders (silver powder and copper powder) with the thicknesses of the clad layers adjusted were prepared, a conductive paste was produced, and the soundness of the junction depending on the ratio of the clad layers was studied. The metal powder was produced in the same manner as in the first embodiment, changing the gold plating conditions as the cladding layer to achieve thicknesses of 0.001 μm, 0.002 μm, 0.005 μm, 0.05 μm, 0.1 μm, and 0.3 μm. Regarding the thickness of the coating layer, the plating conditions were changed so that the gold concentration of the plating solution was 2 to 10 g / L, the plating temperature was set at 60 to 90° C., and the plating time was 1 to 2 hours. In addition, the manufacture of the conductive paste is also the same as that of the first embodiment. In addition, Si chips were similarly bonded on the DBC substrate. In soundness evaluation of the joint between the Si chip and the DBC substrate, the shear strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com