Low-silver-content graphene composite conductive silver paste and preparation method thereof

A technology of composite conductivity and silver content, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Density, reduced production costs, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] (1) Preparation of organic carrier

[0028] Add 80 grams of 1,4-dimethylnaphthalene to a three-necked round-bottom flask, heat it in a water bath to 60oC, measure 20 grams of polyvinyl acetate particles and slowly add it to the above solution, and keep stirring. After the addition of the resin, the water bath temperature Raised to 80oC constant temperature for 8 hours to obtain light yellow transparent viscous resin solution.

[0029] (2) Preparation of base silver paste

[0030] Take 30 grams of the organic carrier solution prepared in (1), add it to a 200 ml beaker, keep stirring slowly, successively measure 2 grams of turpentine oil and 0.3 grams of methyl silicone oil into the carrier solution, stir at a high speed until the mixture is uniform, and then weigh 10 gram of graphene flakes, slowly add, keep stirring, after adding, stir at a high speed until graphene flakes are evenly dispersed in the carrier, then measure 60 grams of silver-coated glass powder (silver-...

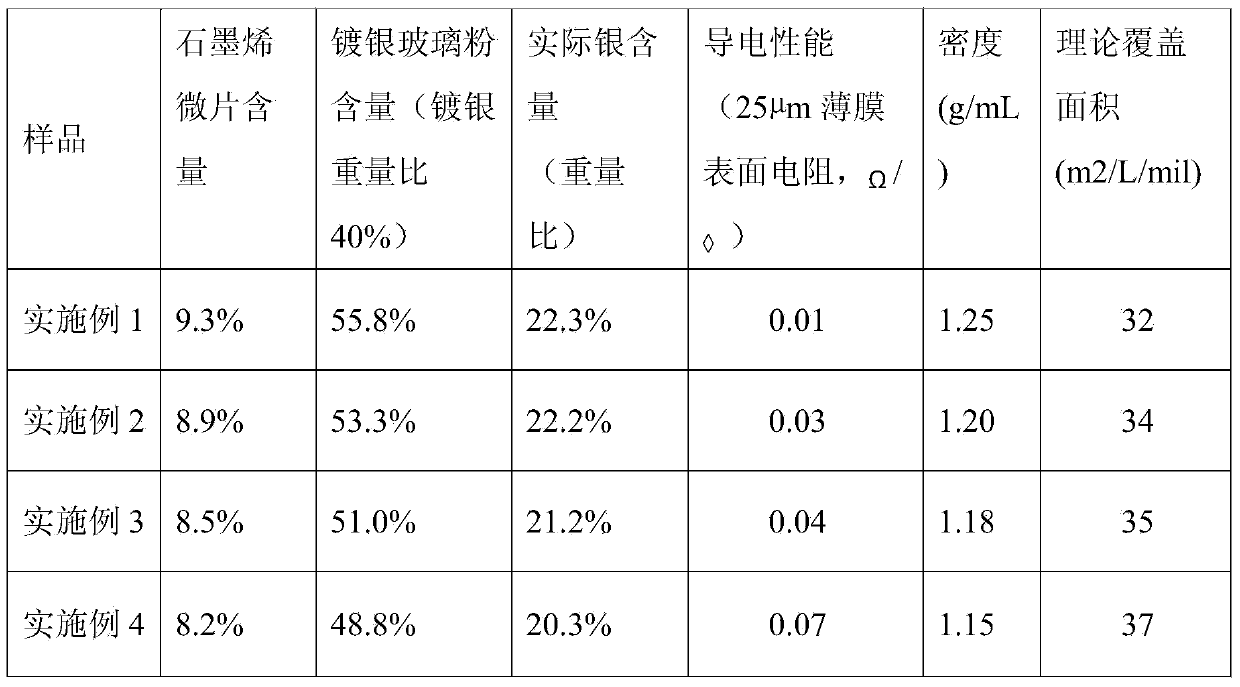

Embodiment 1

[0033] Take 20 grams of the base silver paste prepared in (2), add 1 gram of 1,4-dimethylnaphthalene, and mix at a high speed in a high-speed disperser until the slurry is uniform. After cooling to room temperature, measure its viscosity to be about 50,000 centimeters moor. The silver paste was printed onto the PET film by screen printing (220 mesh screen), and dried in a constant temperature oven at 120oC for 10 minutes to obtain a conductive film with a thickness of about 25 μm, and then the conductivity of the conductive film was measured. The various performance data of silver paste and conductive film are summarized in Table 1.

Embodiment 2

[0035] Take 20 grams of the base silver paste prepared in (2), add 2 grams of 1,4-dimethylnaphthalene, and mix at a high speed in a high-speed disperser until the slurry is uniform. After cooling to room temperature, measure its viscosity to be about 40,000 centimeters moor. The silver paste was printed onto the PET film by screen printing (220 mesh screen), and dried in a constant temperature oven at 120oC for 10 minutes to obtain a conductive film with a thickness of about 25 μm, and then the conductivity of the conductive film was measured. The various performance data of silver paste and conductive film are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com