YSZ (yttria-stabilized-zirconia)-based HCs gas sensitive sensor based on NiO sensitive electrode and preparation method of YSZ (yttria-stabilized-zirconia) -based HCs gas sensitive sensor

A gas-sensing sensor and sensitive electrode technology, which is applied to instruments, scientific instruments, electrochemical variables of materials, etc., can solve the problems of obvious influence on response performance, and achieve the effects of strong anti-interference ability, high response and sensitivity, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

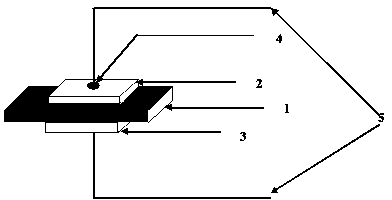

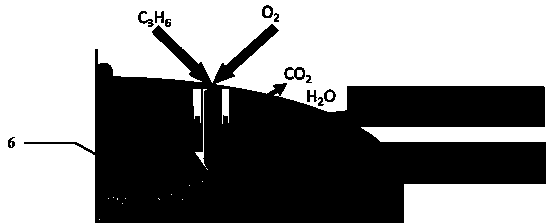

[0040] A kind of preparation method based on NiO sensitive electrode YSZ base HCs gas sensor disclosed by the present invention as claimed in claim 1, comprises the following steps:

[0041] A Use tape casting technology to make YSZ green ceramic sheets with a thickness of 0.5-0.7 mm (excluding 0.6 mm), and put them into a sintering furnace after debinding for 20 hours at 350 ° C ~ 400 ° C in the air;

[0042] B The NiO sensitive electrode material with flower-like nano-morphology is prepared by hydrothermal synthesis method;

[0043] One side of the YSZ solid electrolyte described in C is provided with a sensitive electrode slurry of porous nano-NiO, and the preparation method of the sensitive electrode slurry is to mix the NiO powder prepared in B with terpineol slurry (by 70% terpineol+30 % ethyl cellulose preparation) in an agate mortar and mix and grind evenly, the thickness of the sensitive electrode is 20-30 μm;

[0044] D After drying the sample ob...

Embodiment 7

[0054] The difference between Examples 7-11 and Examples 1-5 is that the particle size of NiO nanomaterials used for sensitive electrodes is 80-120nm, and the content of NiO nanomaterials is 25-30% (wt) prepared by terpineol slurry , after multiple times of printing by screen printing technology, the thickness of the sensitive electrode described in the above table Examples 1-5 is formed, and the thickness of the solid electrolyte The debinding temperature corresponds to the debinding temperature in Examples 1-5 and is respectively changed to: 358°C, 350°C, 380°C, 370°C, 400°C . That is, the debinding temperature in Example 7 is 358°C; the debinding temperature in Example 8 is 350°C; the debinding temperature in Example 9 is 380°C; the debinding temperature in Example 10 is 370°C; The temperature of the glue is 400°C (the other parts of this article are expressed in a similar way to the line drawn in this paragraph, and the explanations are similar to this sentence, except fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com