Visibility calibration instrument, calibration system and product machine calibration method based on calibration system

A visibility and calibration technology, applied in the direction of instrumentation, transmittance measurement, etc., can solve the problems of inaccurate calibration, inconsistent scattering, low precision, etc., and achieve the effect of accurate data calibration, good performance consistency and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

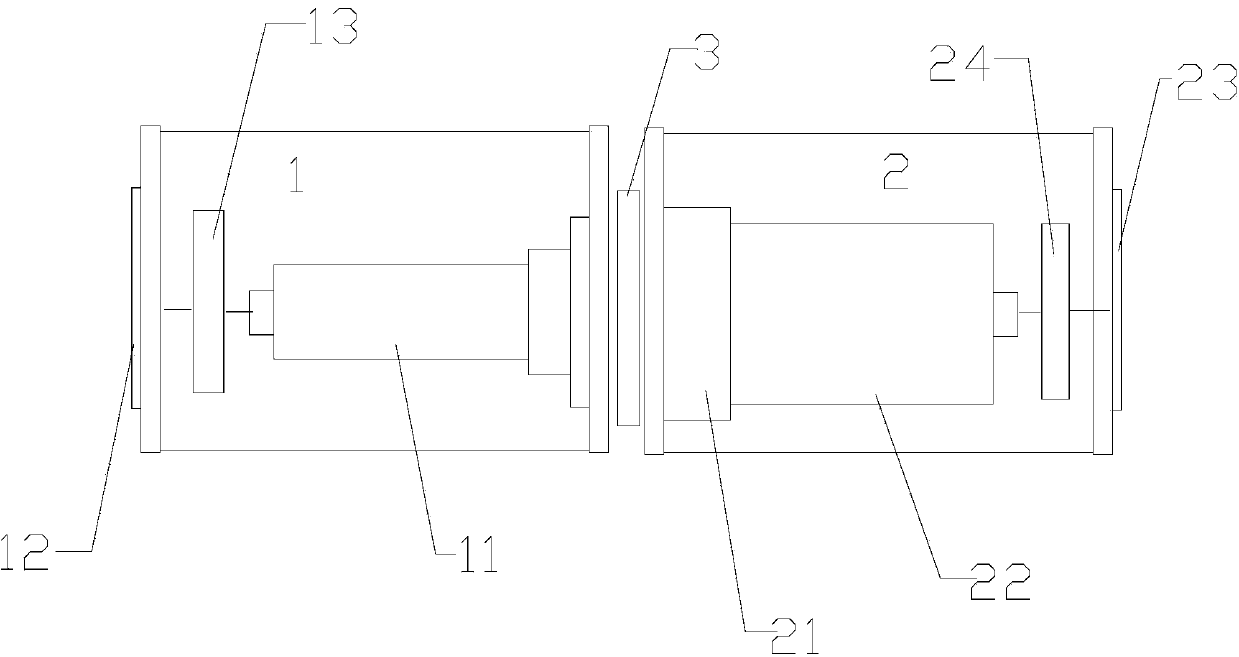

[0067] In this example, the operation steps of the calibration method of the product machine based on the visibility calibration system are as follows:

[0068] 1) Calibrate the calibration instrument, that is, transfer the original reference to the first-level reference:

[0069] In a clean room, the specific indicators of each instrument are: the collimated beam of the transmitter of the calibrator is 30 mm in diameter, the luminous flux is B1 = 12 lumens, and the diameter of the receiving lens is 80 mm to ensure that all collimated light can be received. There are 3 optical attenuation sheets, corresponding to the three types of visibility, high, medium and low. As the original benchmark, it is a measurement benchmark, and its performance is recognized by the authority. The original benchmark equivalent extinction coefficient or visibility data. According to the visibility calculation formula MOR=ln0.05 / σ=L*ln0.05 / lnT, the data in Table 1 can be obtained.

[0070] Table 1 Compari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com