High-temperature cyclone separation type three-waste co-combustion furnace

A technology of cyclone separation and co-combustion furnace, which is applied in the direction of incinerators, combustion methods, combustion types, etc., and can solve the problems of inability to return materials, waste energy, and reduce the combustion efficiency of co-combustion furnaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

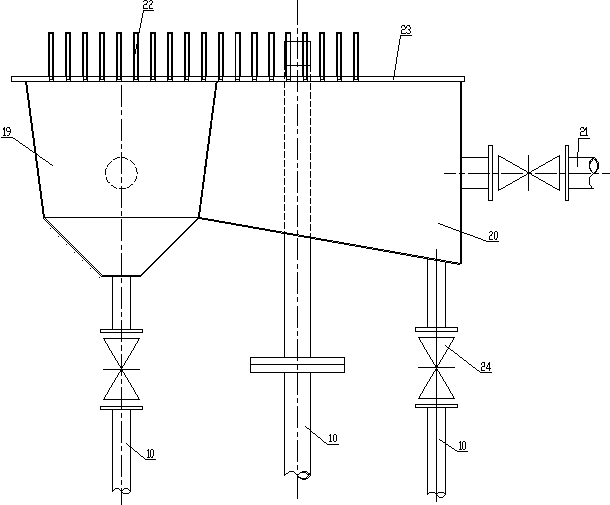

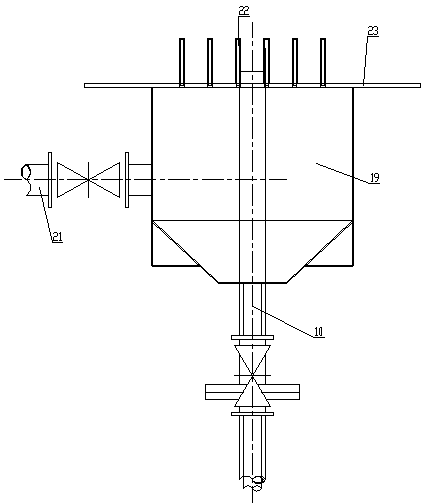

[0019] Such as Figure 1 to Figure 4 As shown, the high-temperature cyclone separation type three-waste mixed combustion furnace includes a combustion furnace 30 and a separator 9 communicating with the ash outlet 17 of the combustion furnace 30 . The combustion furnace 30 comprises a conical section arranged at the bottom and a cylindrical section arranged at the top. The diameter of the conical section gradually increases from bottom to top, and its maximum diameter is equal to the diameter of the cylindrical section; The diameter of the section is equal to the minimum diameter of the conical section of the combustion furnace 30. Two sets of spiral coal feeders 14 are installed on the side of the combustion section, and an air chamber 8 is installed on the bottom of the combustion section. An igniter 7 is installed on the side, and an air distribution device 6 is arranged horizontally between the combustion section and the air chamber. The combustion furnace 30 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com