High-efficiency safe method for mixing oxygen and combustible gas

A technology of gas mixing and oxygen, which is applied in the direction of mixing methods, gas and gas/steam mixing, mixers, etc., can solve the problems of low mixing efficiency and unsafety, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

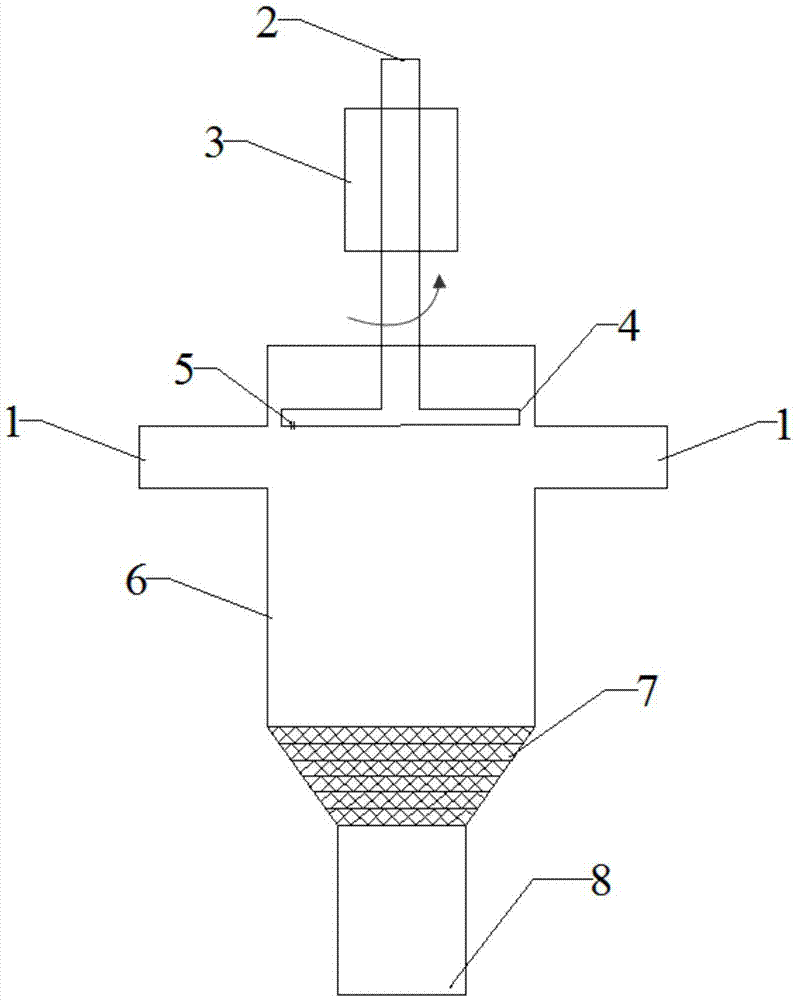

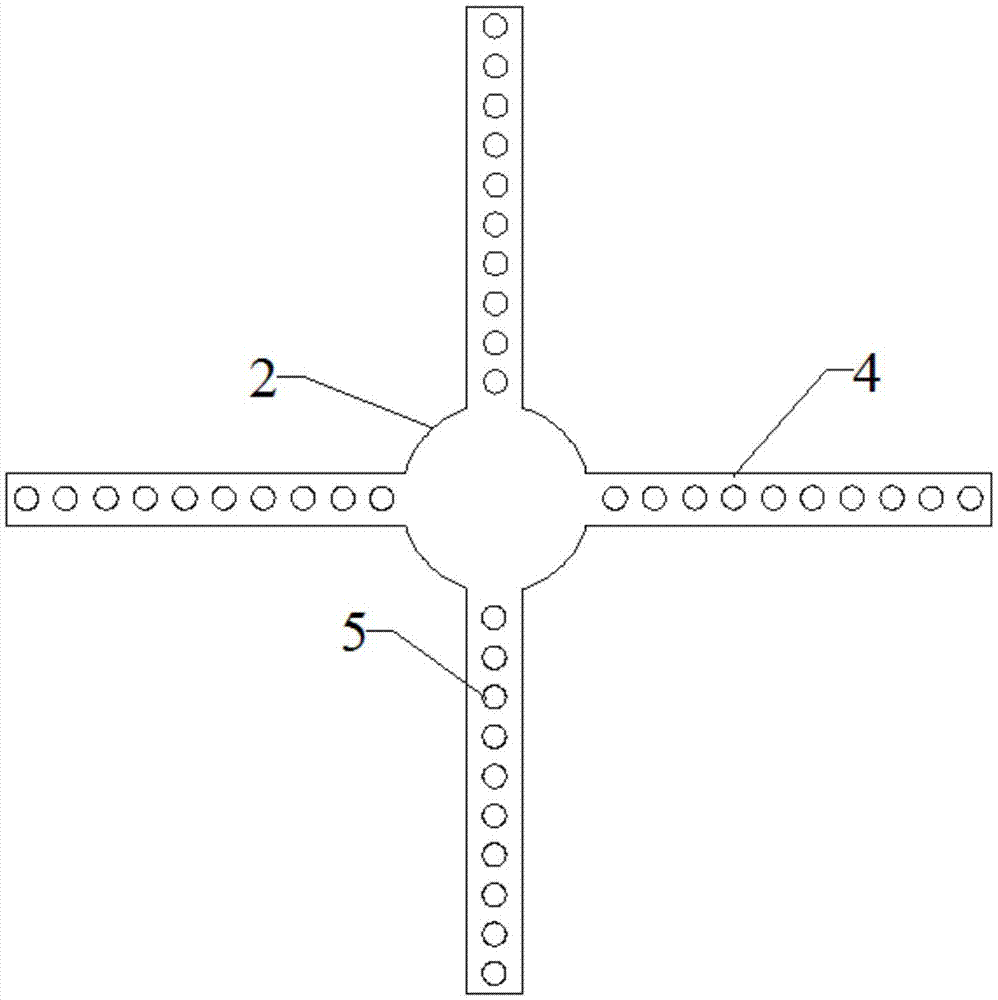

[0018] Such as figure 1 As shown, the gas mixing device includes an oxygen inlet and distribution device, a combustible gas inlet, a cylindrical mixing space, a flame arresting device and a mixed gas outlet. Two combustible gas inlet pipes 1 are evenly arranged around the gas mixing space, through which the combustible gas enters the gas mixing space 6 and forms a cross-flow flow with oxygen. The oxygen intake and distribution device comprises an oxygen intake pipe 2, a motor rotating device 3 connected thereto, an oxygen distribution branch pipe 4 and jet holes 5 on the branch pipe, as figure 2 As shown in the top view of the oxygen distribution device, the oxygen distribution branch pipe 4 is arranged at the bottom of the oxygen intake pipe 2 and is perpendicular to it. , Isometric circular hole. Oxygen enters each oxygen distribution branch pipe 4 from the oxygen intake pipe 2, and is sprayed out from the jet hole 5 on the branch pipe. The motor rotating device 3 drives ...

Embodiment 2

[0021] According to the conditions and steps described in Example 1, four combustible gas inlet pipes 1 are evenly arranged around the gas mixing space, and the number of oxygen distribution branch pipes is four. The opening ratio of the oxygen distribution branch pipe is 0.36%. The rotation speed of the motor rotating device is 1200rpm. The fire retardant device is filled with corrugated fire retardant materials. The ratio of the height of the fire retardant zone to the gas mixing space is 0.4. The ratio of the pipe diameter of the mixed gas outlet to the diameter of the gas mixing space is 0.48.

Embodiment 3

[0023] According to the conditions and steps described in Example 1, six combustible gas inlet pipes 1 are uniformly arranged around the gas mixing space, and the number of oxygen distribution branch pipes is six. The opening ratio of the oxygen distribution branch pipe is 0.45%. The rotation speed of the motor rotating device is 1000rpm. The fire retardant device is filled with corrugated fire retardant materials. The ratio of the height of the fire retardant zone to the gas mixing space is 0.2. The ratio of the pipe diameter of the mixed gas outlet to the diameter of the gas mixing space is 0.52.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com