A power recovery and cooling system using the waste heat of blast furnace slag flushing water

A blast furnace slag flushing water and power recovery technology is applied in the fields of energy and environment. The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

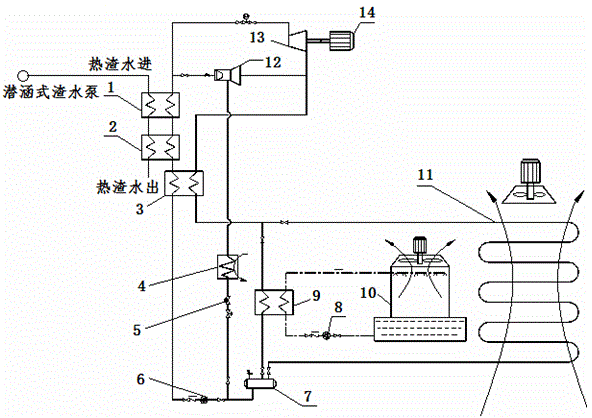

[0027] Embodiment 1: as Figure 1-2 As shown, a power recovery and cooling system using the waste heat of blast furnace slag flushing water, including a slag flushing water heat recovery heat exchange system, an organic Rankine cycle, a steam injection refrigeration system, and a cooling water circulation system;

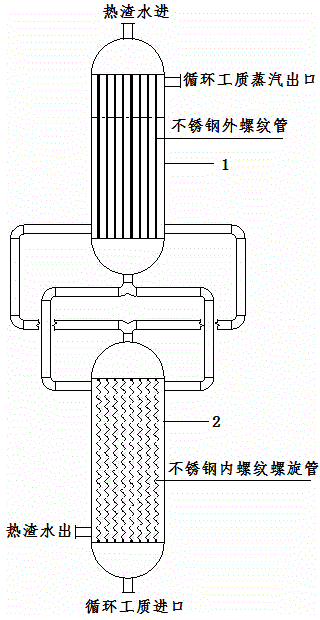

[0028] The slag flushing water heat recovery heat exchange system is composed of a preheater 2, a steam generator 1 and the pipes and accessories connecting them; the low-pressure steam pipe is connected with the steam generator 1 hot fluid side inlet, and the steam generator 1 The outlet on the fluid side is connected to the hot fluid side inlet of the preheater 2 through pipes, and the hot fluid side outlet of the preheater 2 is connected to the condensate pipeline;

[0029] The organic Rankine cycle consists of a working fluid storage tank 7, a working fluid booster pump 6, a regenerator 3, a preheater 2, a steam generator 1, a turbine 13, a water-cooled cond...

Embodiment 2

[0032] Embodiment 2: as Figure 1-2 As shown, a power recovery and cooling system using waste heat of blast furnace slag flushing water, this embodiment is the same as embodiment 1, wherein the power recovery and cooling system using waste heat of blast furnace slag flushing water also includes a direct air cooling system, The direct air-cooling system consists of an air-cooled condenser 11, a working fluid storage tank 7, and pipes and accessories connecting them; The outlet of the heat flow side of the condenser 11 is connected with the inlet of the working fluid storage tank 7 through a pipeline.

Embodiment 3

[0033] Embodiment 3: as Figure 1-2 As shown, a power recovery and cooling system using waste heat of blast furnace slag flushing water, this embodiment is the same as Embodiment 2, wherein the circulating working medium in the organic Rankine cycle is toluene, R152a, R142b, R22, R123 , R134a, R245fa, propane, R143a, R32, R23, pentane, isopentane, n-pentane, n-hexane, butane, isobutane pure organic working fluid or toluene, R152a, R142b, R22, R123, R134a , R245fa, propane, R143a, R32, R23, pentane, isopentane, n-pentane, n-hexane, butane, isobutane mixture of pure organic refrigerants and then mixed with carbon dioxide mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com