Transparent bushing tube for drilling and coring of soft formation

A soft stratum and liner technology, which is applied in the direction of extraction of undisturbed cores, earthwork drilling, etc., can solve the problems affecting the processing speed of core logging, disordered order, disordered dip and inclination, etc., and achieve consistent longitudinal sectioning angles. stability, simplify work operation procedures, and eliminate the effect of direction inversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure and application principle of the present invention will be described in detail below in conjunction with specific embodiments.

[0018] The embodiment of the present invention consists of a transparent resin pipe and signs on the outer surface.

[0019] Such as figure 1 As shown, the transparent liner 1 is made of UPVC or ABS transparent pipe, and its diameter and length range: the outer diameter is 60-168 mm, the inner diameter is 52-150 mm, and the length is 6096-9144 mm. core, as well as core logging and laboratory core processing. The UPVC liner is suitable for working in an environment below 70°C; the ABS liner is suitable for working in an environment below 80°C.

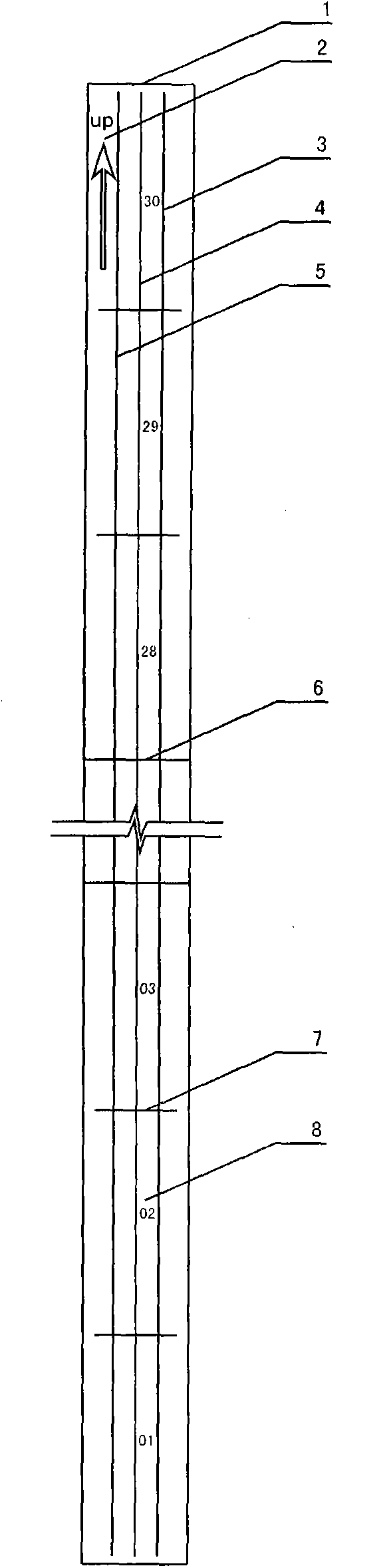

[0020] Such as figure 2 As shown, the arrow pointing upward and the UP character 2 are marked on one end of the transparent liner 1, and the arrow points to the end. At this time, the direction pointed by the arrow is upward, and the English UP mark is above the arrow; when the transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com