Hole bottom freezing cord coring drill and coring method thereof

A core drilling tool and hole bottom technology, which is applied in the direction of extracting the undisturbed core device, earthwork drilling, etc., can solve the problems of poor effect, long drilling time, heavy workload, etc., and achieve improved recovery rate, good freezing effect, The effect of quick freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

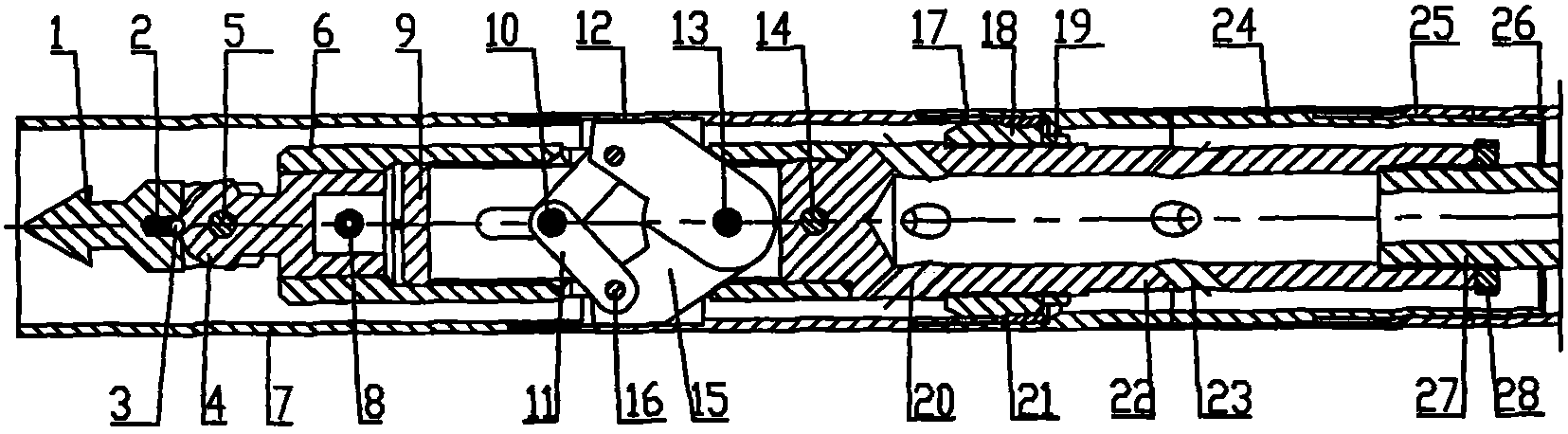

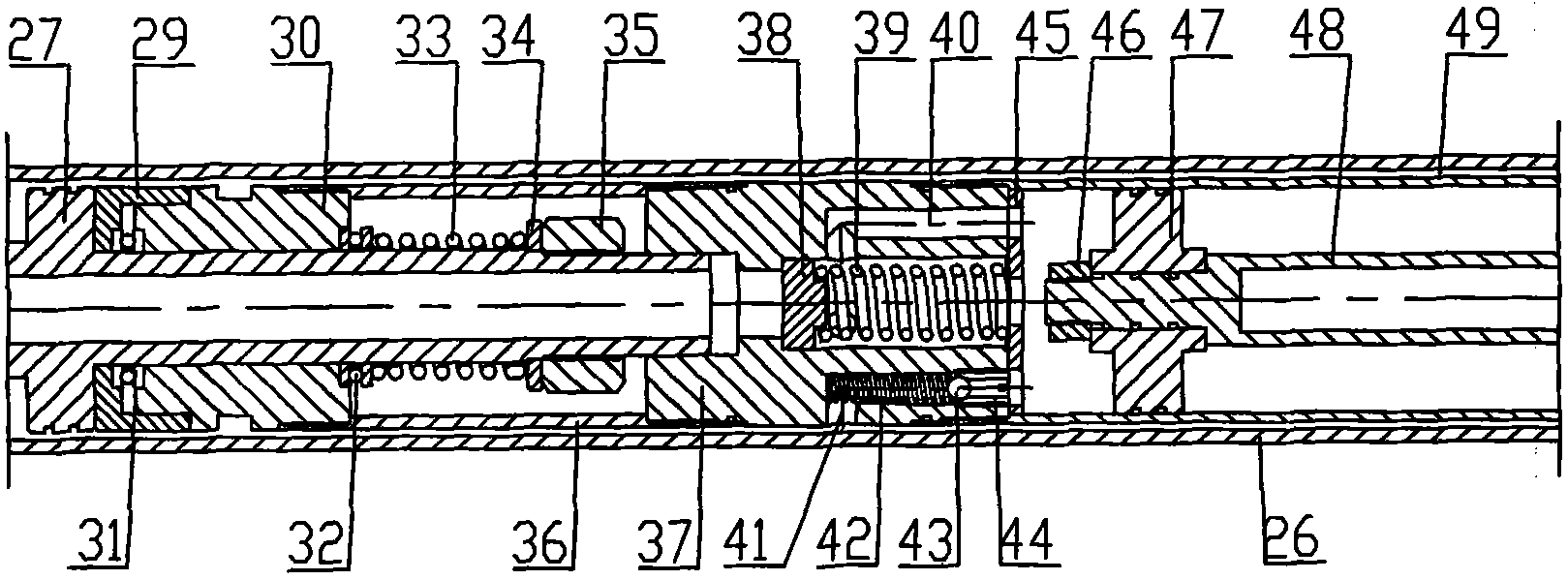

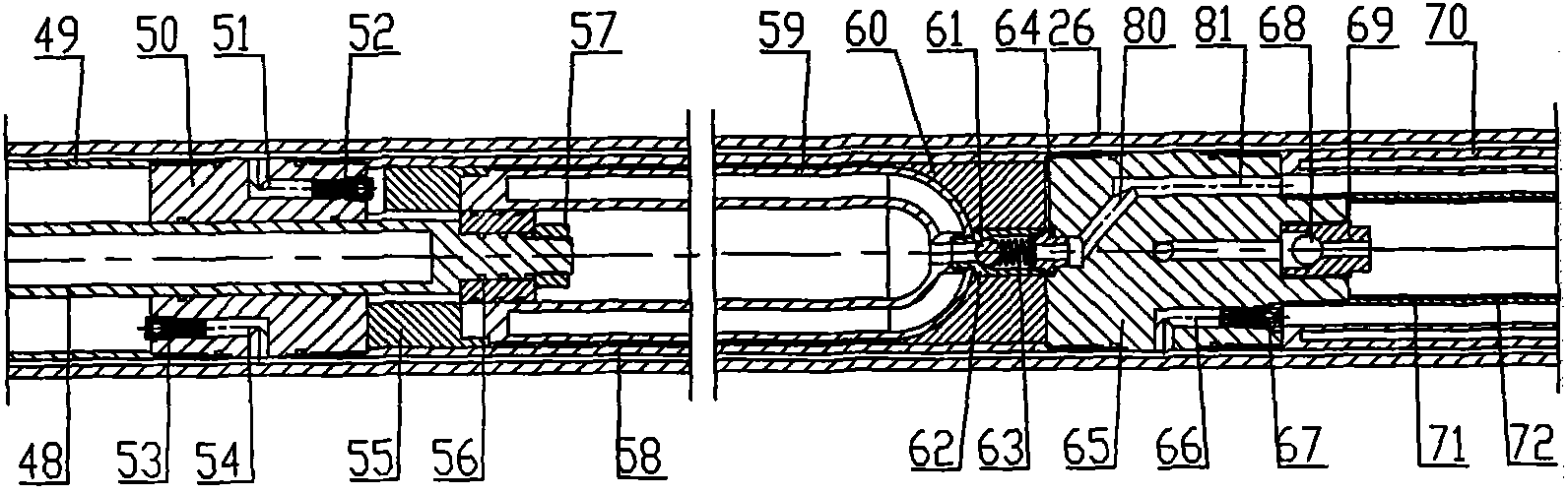

[0033] Hole Bottom Frozen Wireline Coring Tools

[0034] First assemble the outer tube assembly: the cartridge chamber 12 is threadedly connected with the cartridge stop head 7, the upper part of the inner spline short 17 is threadedly connected with the cartridge chamber 12, the lower end is threadedly connected with the inner spline 25, and the inner spline 25 is connected with the outer The spline 24 fits through the spline, and the outer spline 24 slides in the axial direction. The steps on the inner wall of the inner spline 25 and the outer wall of the outer spline 24 limit the sliding distance of the outer spline 24 in the axial direction. The outer spline 24 passes through the screw thread. Connect the outer tube 27, the guide ring 73 is embedded in the inner wall of the lower end of the outer tube 26, the reamer 74 is connected to the thread at the lower end of the outer tube 26, and the guide ring 73 is pressed tightly, and the lower end of the reamer 74 is connected t...

Embodiment 2

[0048] Hole Bottom Frozen Wireline Coring Tools

[0049] First assemble the outer tube assembly: the cartridge chamber 12 is threadedly connected with the cartridge stop head 7, the upper part of the inner spline short 17 is threadedly connected with the cartridge chamber 12, the lower end is threadedly connected with the inner spline 25, and the inner spline 25 is connected with the outer The spline 24 fits through the spline, and the outer spline 24 slides in the axial direction. The steps on the inner wall of the inner spline 25 and the outer wall of the outer spline 24 limit the sliding distance of the outer spline 24 in the axial direction. The outer spline 24 passes through the screw thread. Connect the outer tube 27, the guide ring 73 is embedded in the inner wall of the lower end of the outer tube 26, the reamer 74 is connected to the thread at the lower end of the outer tube 26, and the guide ring 73 is pressed tightly, and the lower end of the reamer 74 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com