Silk hemp cellulose fiber and preparation method thereof

A technology of cellulose fiber and alkali cellulose, which is applied in the field of silk and hemp cellulose fiber and its preparation, and the preparation of hemp pulp modified protein fiber. Problems such as protein fiber quality, achieve good solubility, adjustable HLB value, and obvious synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

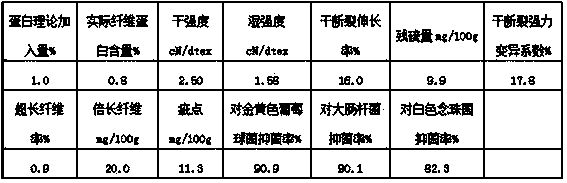

Examples

Embodiment 1

[0046] A kind of preparation method of silk hemp cellulose fiber, concrete preparation method is as follows:

[0047] 1. Preparation of hemp pulp viscose spinning stock solution:

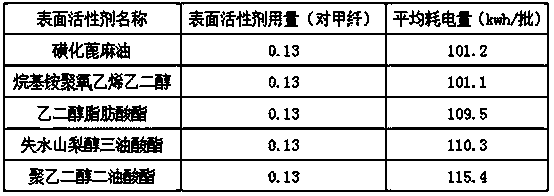

[0048] 1. Impregnated powder of hemp pulp cellulose

[0049] The hemp pulp with a degree of polymerization of 400 and a methylcellulose content ≥ 90% is soaked once in a solution of sodium hydroxide and a surfactant accounting for 0.03wt% of methylcellulose in the hemp pulp at a concentration of 250g / l and a temperature of 52°C. Carry out a press to obtain the first alkali cellulose with a cellulose of 22.5% and an alkali content of 16%, and then impregnate it twice in a sodium hydroxide solution with a concentration of 178g / l and a temperature of 50°C and obtain a cellulose after a second press. The secondary alkali cellulose with a fiber content of 28.5% and an alkali content of 14.0% was added with 0.03 wt% pulverizing denaturant of p-methyl cellulose and then pulverized to obtain alkali fiber w...

Embodiment 2

[0067] 1. Preparation of hemp pulp viscose spinning stock solution:

[0068] 1. Impregnated powder of hemp pulp cellulose

[0069] The hemp pulp with a degree of polymerization of 600 and a methylcellulose content ≥ 90% is soaked once in a solution of sodium hydroxide and a surfactant accounting for 0.15wt% of methylcellulose in the hemp pulp with a concentration of 248g / l and a temperature of 56°C. Carry out one pressing to obtain the first alkali cellulose with 27.5% methyl fiber and 19% alkali, and then carry out secondary impregnation in the sodium hydroxide solution with a concentration of 180g / l and a temperature of 53°C and obtain formazan after the second pressing. The secondary alkali cellulose with a fiber content of 30.5% and an alkali content of 14.8% was added with 0.05 wt% pulverizing denaturant of p-methyl cellulose and then pulverized to obtain alkali fiber with a pulverization degree of ≤ 180s.

[0070] 2. The old age of ephedrine cellulose

[0071] Put the ...

Embodiment 3

[0087] 1. Preparation of hemp pulp viscose spinning stock solution:

[0088] 1. Impregnated powder of hemp pulp cellulose

[0089] After immersing hemp pulp with a degree of polymerization of 550 and a methylcellulose content ≥ 90% in a solution with a concentration of 246g / l and a temperature of 54°C of sodium hydroxide and a surfactant accounting for 0.08wt% of methylcellulose in the hemp pulp Carry out a press to obtain the first alkali cellulose with a cellulose of 24.5% and an alkali content of 17.0%, and then impregnate it twice in a sodium hydroxide solution with a concentration of 178g / l and a temperature of 51°C and obtain a cellulose after a second press. The secondary alkali cellulose with a fiber content of 29.5% and an alkali content of 14.3% is added with 0.04wt% pulverizing denaturant of p-methyl cellulose and then pulverized to obtain alkali cellulose with a pulverization degree of alkali fiber ≤ 180s.

[0090] 2. The old age of ephedrine cellulose

[0091] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com