Organosilane modified single-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and organic silane technology, applied in the direction of coating, etc., can solve the problems of thick coating, incomplete coating, waste, etc., and achieve the effect of reducing environmental dependence, solving construction problems, and smooth and beautiful coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

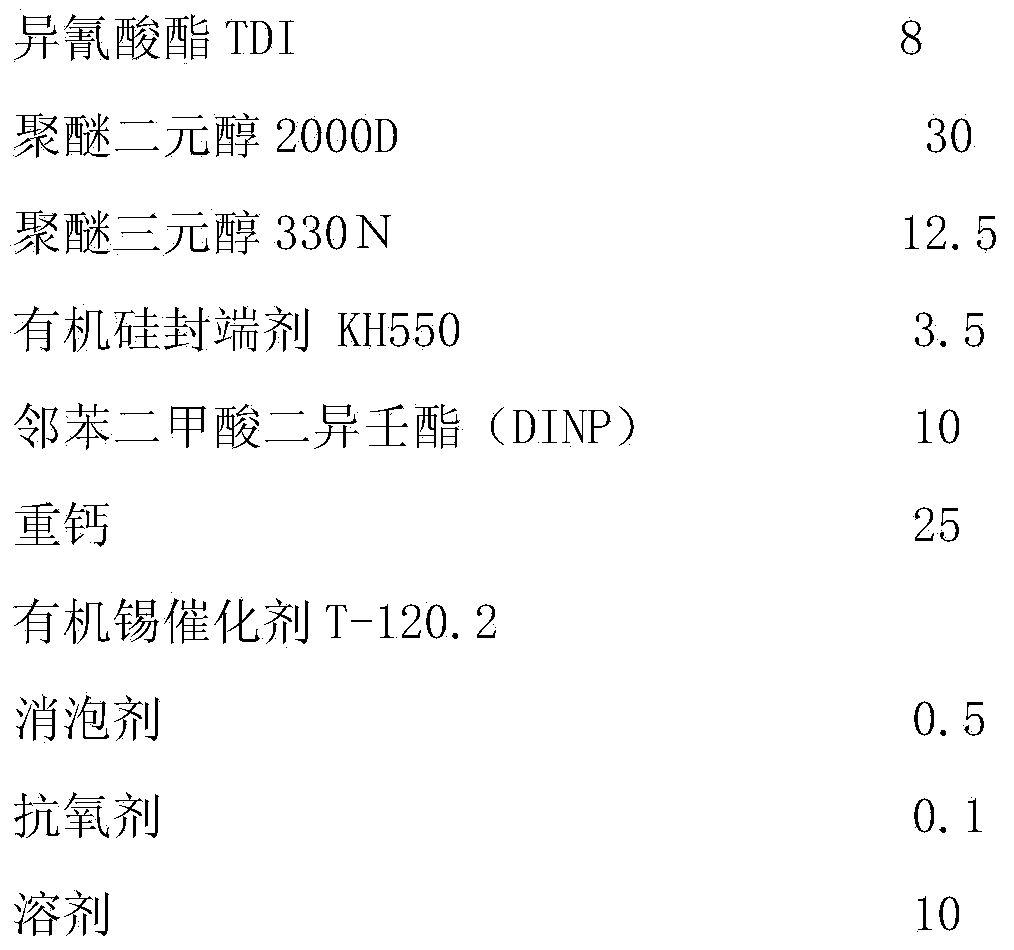

[0026] Embodiment 1: product raw material composition is as follows

[0027]

[0028] crafting process:

[0029] a. Add 30 parts by weight of polyether diol 2000D and 12.5 parts by weight of polyether triol 330N into the reaction vessel, stir and heat up to 100°C-120°C, and dehydrate for 2 to 3 hours under a vacuum of -0.01MPa;

[0030] b. Lower the temperature below 60°C-80°C, add 8 parts by weight of isocyanate TDI, and react for 2-3 hours under stirring at 60-100°C;

[0031] c. Lower the temperature to below 50°C-60°C, add 3.5 parts by weight of an organosilane end-capping agent, and stir at 50-90°C for a silanization reaction for 2 to 3 hours;

[0032] d. Lower the temperature below 50°C-60°C, add 10 parts by weight of diisononyl phthalate (DINP), 25 parts by weight of heavy calcium, 0.2 parts by weight of organotin catalyst T-12, and 0.1 parts by weight of antioxidant 1. 0.5 parts by weight of defoaming agent and 10 parts by weight of solvent, stirred for 1-2 hours, ...

Embodiment 2

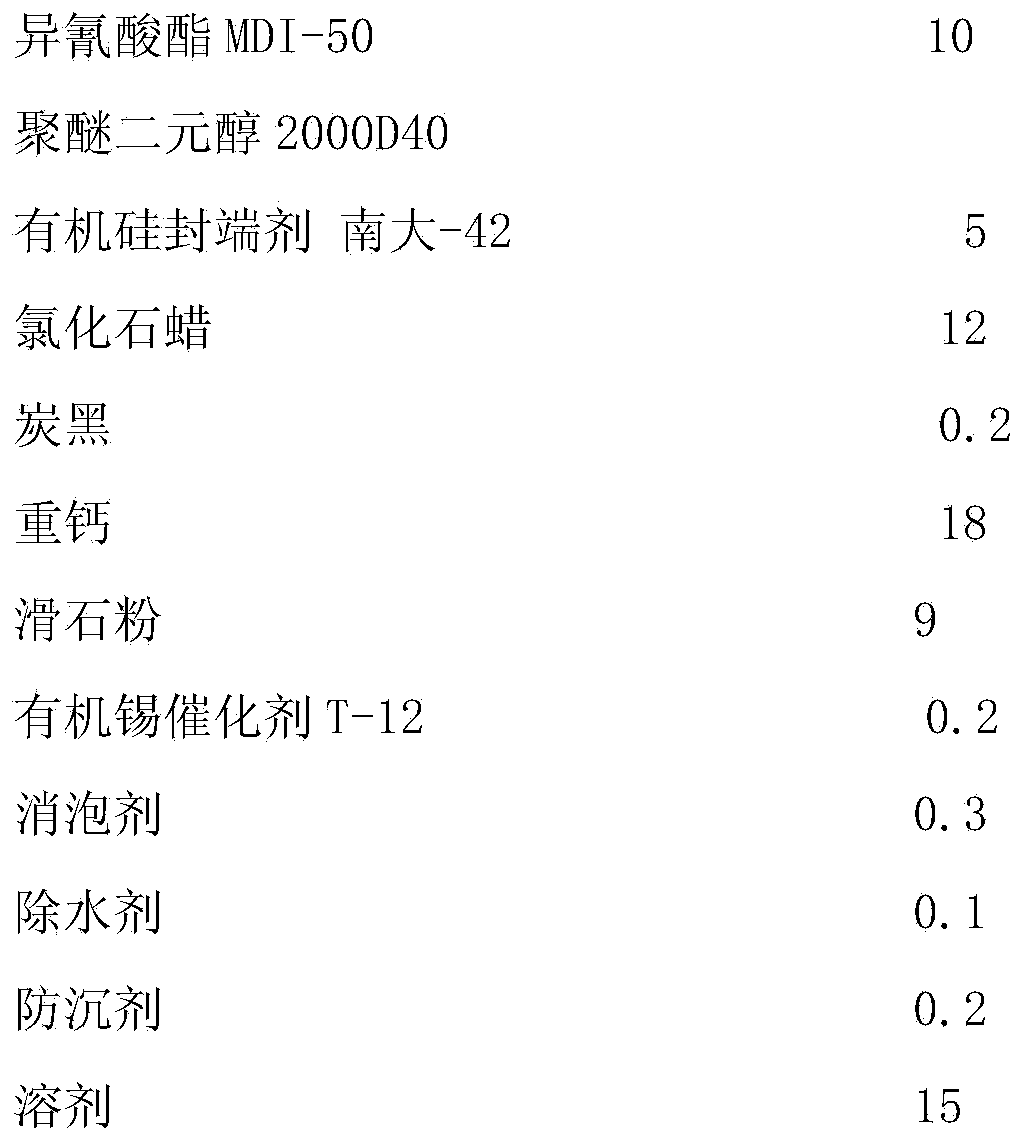

[0033] Embodiment 2: the raw material composition of product is as follows

[0034]

[0035] crafting process:

[0036] a. Add 40 parts by weight of polyether diol 2000D to the reaction vessel, stir and heat up to 100°C-120°C, and dehydrate for 2-3 hours under the condition of vacuum of -0.01MPa;

[0037] b. Lower the temperature below 60°C-80°C, add 10 parts by weight of isocyanate MDI-500, and react for 2-3 hours under stirring at 60-100°C;

[0038] c. Lower the temperature to below 50°C-60°C, add 5 parts by weight of organosilane end-capping agent, and stir at 60-90°C for silanization reaction, and react for 2-3 hours;

[0039] d. Lower the temperature below 50°C-60°C, add 12 parts by weight of chlorinated paraffin, 18 parts by weight of heavy calcium, 9 parts by weight of talcum powder, 0.2 parts by weight of carbon black, 0.2 parts by weight of organotin catalyst T-12, defoaming 0.3 parts by weight of agent, 0.1 parts by weight of dewatering agent, 0.2 parts by weigh...

Embodiment 3

[0040] Embodiment 3: the raw material composition of product is as follows

[0041]

[0042] crafting process:

[0043] a. Add 15 parts by weight of polyether diol 2000D, 10 parts by weight of polyether diol 1000D and 15 parts by weight of polyether triol 2000D in the reaction vessel, stir and raise the temperature to 100°C-120°C, and the vacuum is -0.01 Dehydration under the condition of MPa for 2 to 3 hours;

[0044] b. Lower the temperature below 60°C-80°C, add 6 parts by weight of isocyanate TDI and 6 parts by weight of isocyanate MDI-50, and react for 2 to 3 hours under stirring at 60-100°C;

[0045] c. Lower the temperature to below 50°C-60°C, add 6.6 parts by weight of organosilane end-capping agent, and silanization reaction occurs under stirring at 50-90°C for 2-3 hours;

[0046]d. Lower the temperature below 50°C-60°C, add 10 parts by weight of triethyl citrate, 2 parts by weight of titanium dioxide, 16 parts by weight of heavy calcium, 8 parts by weight of bari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com