High-density polyethylene/graphene/polyaniline composite material and synthetic method thereof

A technology of high-density polyethylene and composite materials, which is applied in the field of high-density polyethylene/graphene/polyaniline composite materials and their synthesis to achieve the effects of improving dispersibility, preventing re-aggregation, and decreasing the degree of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

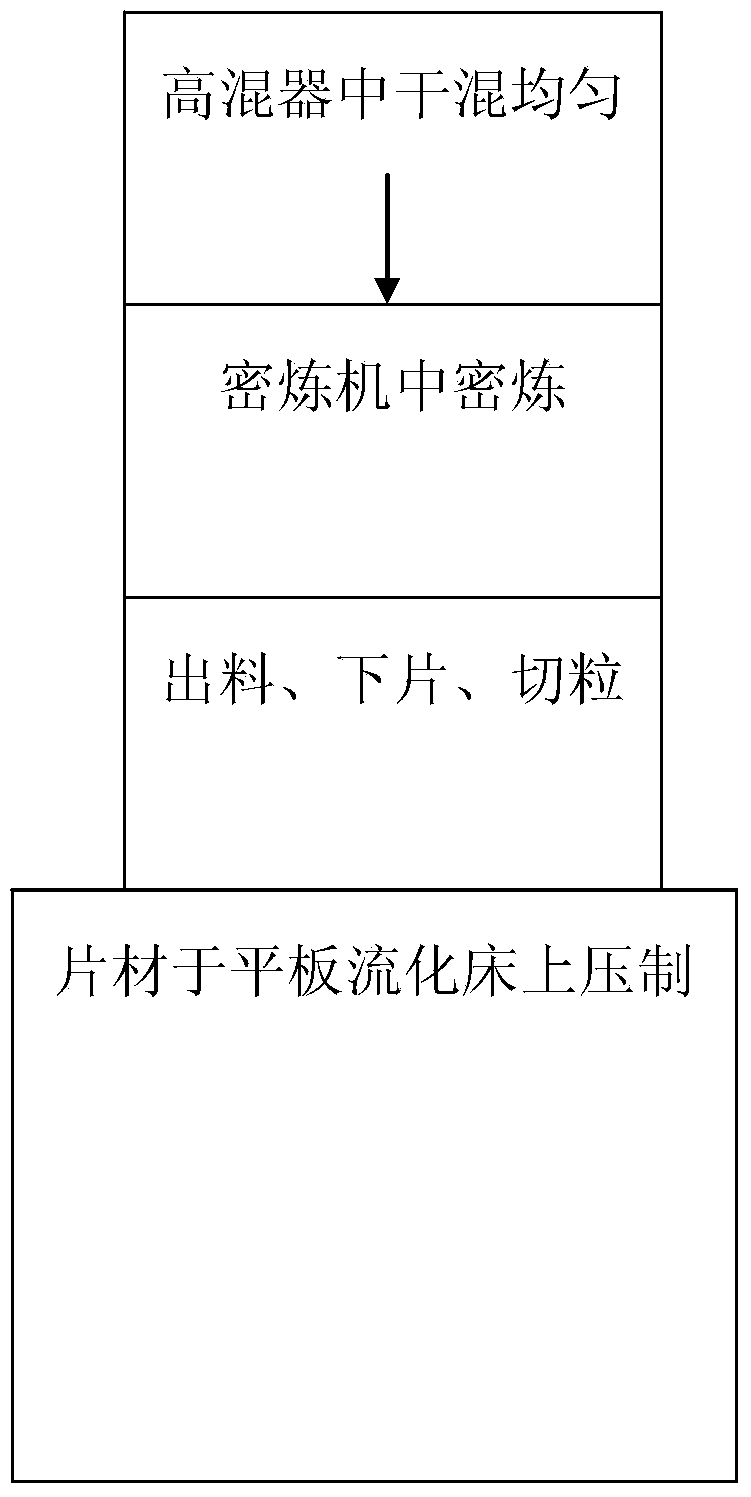

[0029] This embodiment provides the synthetic method of high-density polyethylene / graphene / polyaniline composite material, such as figure 1 shown, including the following steps:

[0030] Step 1: Place the blend of high density polyethylene and polyaniline / graphene in a high mixer and dry mix it evenly;

[0031] Step 2: Plasticizing the mixture formed in Step 1 in an internal mixer;

[0032] Step 3: discharging, unloading, dicing, and obtaining sheets;

[0033] Step 4: Press and shape the sheet on a flat vulcanizing machine.

[0034] Wherein, the preparation method of the graphene / polyaniline blend is as follows: weigh 1.0 g of aniline and add it to the hydrochloric acid solution, add a certain amount of graphene after ultrasonic dispersion, and slowly add a certain amount of persulfuric acid dropwise under mechanical stirring. Ammonium hydrochloric acid solution, after reacting for 4 hours, the product was repeatedly washed and filtered with deionized water until the filtra...

Embodiment 1

[0037] Step 1: Dry mix high-density polyethylene and graphene / polyphenylene copolymer amine in a high-speed mixer, the mass ratio of polyaniline to graphene is 100:2, polyaniline / graphene blend and high The mass ratio of density polyethylene is 1:1;

[0038] Step 2: plasticize the mixture formed in step 1 in a banbury mixer, the banbury temperature is 150°C, and the plasticization time is 15 minutes;

[0039] Step 3: discharging, unloading, dicing, and obtaining sheets;

[0040] Step 4: Press and form the sheet on a flat vulcanizer. The conditions for press forming are 5 minutes of preheating, 5 minutes of hot pressing, pressure of 18 MPa, and temperature of 250°C.

Embodiment 2

[0042] Step 1: Dry mix high-density polyethylene and graphene / polyaniline copolymer in a high-density mixer, the mass ratio of polyaniline to graphene is 100:20, polyaniline / graphene blend and high-density polyethylene The mass ratio of ethylene is 1:3;

[0043] Step 2: plasticize the mixture formed in step 1 in an internal mixer, the banburying temperature is 180°C, and the plasticizing time is 8 minutes;

[0044] Step 3: discharging, unloading, dicing, and obtaining sheets;

[0045] Step 4: Press and form the sheet on a flat vulcanizer. The conditions for press forming are: preheating for 10 minutes, hot pressing for 2 minutes, pressure at 18 MPa, and temperature at 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com