Biochemical treatment process for high-concentration nonbiodegradable coking wastewater

A technology for refractory biodegradation and coking wastewater, which is applied in the field of high-concentration refractory biodegradable coking wastewater treatment technology, can solve the problems of water quality that cannot meet the discharge standard and direct discharge standard, and achieves less secondary pollution, less land occupation, and biochemical efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

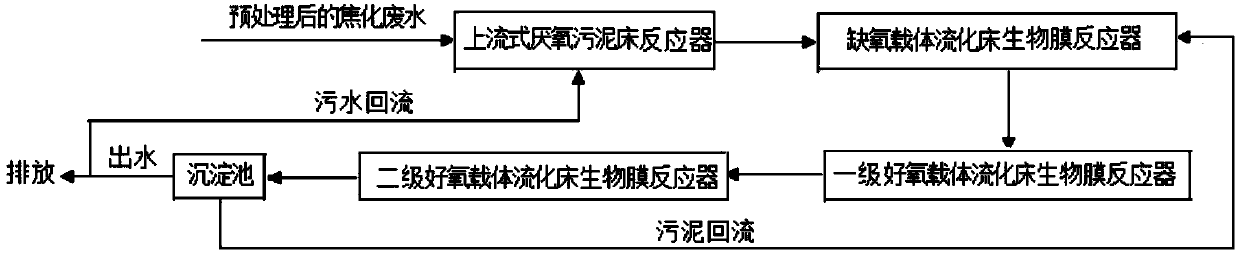

[0015] Such as figure 1 As shown, the coking wastewater with a COD concentration of 6000mg / L, an ammonia nitrogen concentration of 1200mg / L, and a phenol concentration of 500mg / L after pretreatment such as oil separation, air flotation, and adjustment is sent to the upflow anaerobic sludge bed reactor (abbreviated as UASB), the water inflow is 4L / hour, the biochemical treatment is carried out at a temperature of 30°C, a dissolved oxygen of zero, and a pH of 7.0, and the hydraulic retention time is 19 hours; the upflow anaerobic sludge bed reactor The effluent flows into the anoxic carrier fluidized bed biofilm reactor (abbreviated as CBR), where the temperature is 30°C and the dissolved oxygen is less than 0.5mg / L for biochemical treatment, and the hydraulic retention time is 16 hours; the anoxic carrier flow The effluent from the fluidized bed biofilm reactor flows into the first-stage aerobic carrier fluidized bed biofilm reactor for biochemical treatment at a temperature of...

Embodiment 2

[0018] Such as figure 1 As shown, the coking wastewater with a COD concentration of 5500 mg / L, an ammonia nitrogen concentration of 1100 mg / L, and a phenol concentration of 500 mg / L after pretreatment such as oil separation, air flotation, and adjustment is sent to the upflow anaerobic sludge bed reactor In, the water inflow is 11L / hour, biochemical treatment is carried out under the conditions of temperature 35℃, dissolved oxygen zero, pH 7.5, hydraulic retention time is 19 hours; the effluent of the upflow anaerobic sludge bed reactor flows into the anoxic In the carrier fluidized bed biofilm reactor, the biochemical treatment is carried out at a temperature of 32°C and dissolved oxygen less than 0.5mg / L, and the hydraulic retention time is 15 hours; the effluent of the anoxic carrier fluidized bed biofilm reactor flows into a In the first-class aerobic carrier fluidized bed biofilm reactor, the biochemical treatment is carried out at a temperature of 32°C, a dissolved oxyge...

Embodiment 3

[0021] Such as figure 1As shown, the coking wastewater with a COD concentration of 5500 mg / L, an ammonia nitrogen concentration of 1000 mg / L, and a phenol concentration of 400 mg / L after pretreatment such as oil separation, air flotation, and adjustment is sent to the upflow anaerobic sludge bed reactor In the process, the water inflow is 4L / hour, the biochemical treatment is carried out under the conditions of temperature 40℃, dissolved oxygen zero and pH 6.5, and the hydraulic retention time is 10 hours; the effluent of the upflow anaerobic sludge bed reactor flows into the anoxic In the carrier fluidized bed biofilm reactor, the biochemical treatment is carried out at a temperature of 35°C and dissolved oxygen less than 0.5mg / L, and the hydraulic retention time is 10 hours; the effluent of the anoxic carrier fluidized bed biofilm reactor flows into a In the first-class aerobic carrier fluidized bed biofilm reactor, the biochemical treatment is carried out at a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com