A method for repairing and remanufacturing the outer surface of a hydraulic cylinder piston rod or an intermediate cylinder

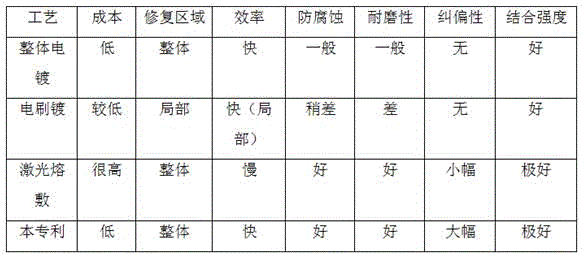

A technology of piston rod and outer surface, applied in the field of equipment repair and remanufacturing, can solve the problems of limiting the wide application of surface laser cladding, unacceptable time period of repair, and thin single-layer thickness of surface cladding, and achieves good economical application. performance, avoid serious environmental pollution problems, and improve the effect of repair performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

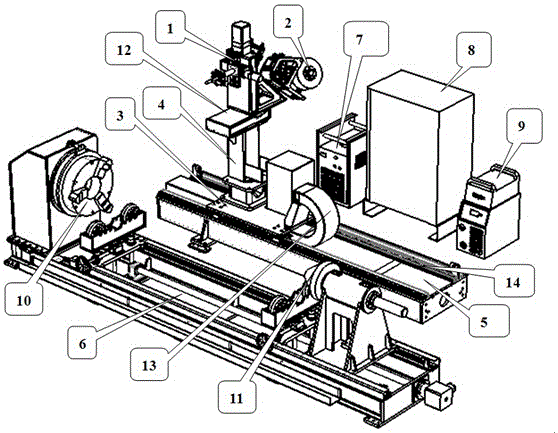

Method used

Image

Examples

Embodiment 1

[0047] The repair and remanufacturing of the outer surface of the hydraulic cylinder piston rod or intermediate cylinder with an outer diameter of Ф380mm includes the following steps:

[0048] (1) Clamp the piston rod or intermediate cylinder on a standard lathe, turn to remove the remaining electroplating layer on the surface,

[0049] Turning thickness is 1.0mm;

[0050] (2) Perform sandblasting on the outer surface of the treated piston rod or intermediate cylinder, using 18-mesh brown corundum sand material, and the sandblasting air pressure is 0.7Mpa. After sandblasting, use the same pressure of high-pressure gas to clean the surface after sandblasting;

[0051] (3) Place the piston rod or intermediate cylinder treated in step (2) in an oven for preheating, the preheating temperature is 100°C±10°C, and the preheating time is 30 minutes;

[0052] (4) Immediately clamp the piston rod or intermediate cylinder preheated in step (3) on the arc thermal spraying device for arc th...

Embodiment 2

[0058] Repair and remanufacture the outer surface of the piston rod or intermediate cylinder with an outer diameter of Ф260mm:

[0059] (1) Clamp the piston rod or intermediate cylinder on a standard lathe, turn to remove the remaining electroplating layer on the surface,

[0060] Turning thickness is 1.0mm;

[0061] (2) Perform sandblasting on the outer surface of the treated piston rod or intermediate cylinder, using 18-mesh brown corundum sand material, and the sandblasting air pressure is 0.7Mpa. After sandblasting, use the same pressure of high-pressure gas to clean the surface after sandblasting;

[0062] (3) Place the piston rod or intermediate cylinder treated in step (2) in an oven for preheating, the preheating temperature is 100°C±10°C, and the preheating time is 30 minutes;

[0063] (4) Immediately clamp the piston rod or intermediate cylinder preheated in step (3) on the arc thermal spraying device for arc thermal spraying. The specific spraying parameters are: u...

Embodiment 3

[0069] Repair and remanufacture the outer surface of the piston rod with an outer diameter of Ф150mm:

[0070] (1) Clamp the piston rod on a standard lathe, turn to remove the remaining electroplating layer on the surface, and turn the thickness

[0071] 0.8mm;

[0072] (2) Sandblast the outer surface of the treated piston rod, using 20-mesh brown corundum sand material for sandblasting, with a sandblasting air pressure of 0.6Mpa, and use high-pressure gas of the same pressure to clean the surface after sandblasting;

[0073] (3) Place the piston rod treated in step (2) in an oven for preheating, the preheating temperature is 100°C±10°C, and the preheating time is 30 minutes;

[0074] (4) Immediately clamp the piston rod preheated in step (3) on the arc thermal spraying device for arc thermal spraying. The specific spraying parameters are: use powder core wire with a diameter of 1.6mm for arc thermal spraying, thermal spraying When the voltage is controlled at 39V, the curre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com