Molds suitable for preparing bulk bulk amorphous alloys and their composite materials

A technology for amorphous alloys and composite materials, which is applied in the field of molds for preparing large-volume bulk amorphous alloys and their composite materials, can solve problems such as inconvenience in use and complicated processing technology, avoid repeated processing, and save mold materials and shapes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Arc melting casting 10000mm 3 CuZrAlY amorphous plate

[0034] 1) Zr with a purity of 99.8%, Cu, Al, and Y with a purity of 99.99% according to Cu 45 Zr 45 Al 8 Y 2 100g of the nominal composition ingredients, placed in the electric arc furnace;

[0035] 2) Vacuum the electric arc furnace, and the vacuum degree reaches 5×10 -3 After the Pa is filled with argon to 0.8 atmospheric pressure, the molten Ti absorbs oxygen first, and then the prepared raw materials are smelted for 3 to 5 times to ensure that the composition is uniform, and a button-shaped master alloy ingot is obtained.

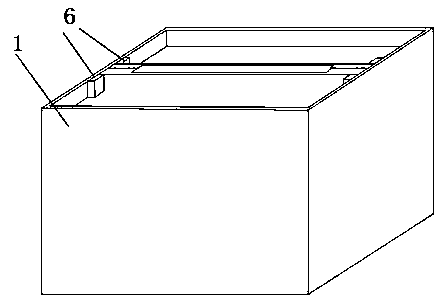

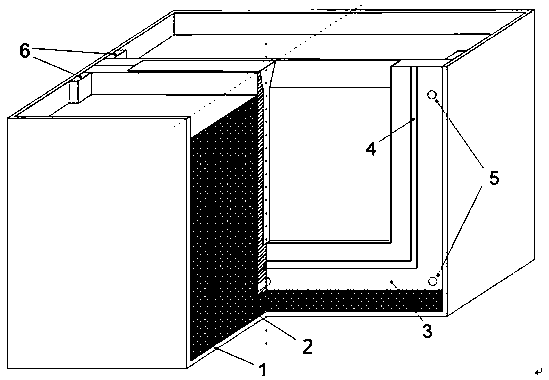

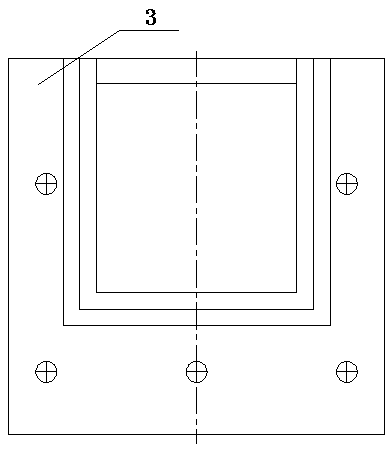

[0036] 3) see image 3 , Figure 4 , Figure 5 , select the cavity size as 50×50×4mm 3 The inner mold 3 of the inner mold 3 is used to prepare a rectangular sheet amorphous, and the sealing strip 4 is placed in the positioning slot 6 of the inner mold 3. After the two halves of the inner mold 3 are fastened with the fastening bolts 5, the copper inner mold 3 is inserted...

Embodiment 2

[0040] Example 2: Induction melting casting 7000mm 3 CuZrTi amorphous composite wafer

[0041] 1) Zr with a purity of 99.8%, Cu and Ti with a purity of 99.99% are compared with Cu 60 Zr 30 Ti 10 Put 50g of the nominal ingredients into a magnesia crucible with an inner diameter of 60mm and a depth of 80mm;

[0042] 2) see Image 6 , Figure 7 , Figure 8 , choose an inner mold with a cavity size of Φ60mm and a thickness of 2.5mm to prepare circular sheet amorphous, place the sealing strip 4 in the positioning slot 6 of the inner mold 3, and fasten the two halves of the inner mold 3 together with fastening bolts 5 After the mold is fastened, insert the copper inner mold 3 into the positioning slot 6 of the stainless steel outer mold 1 and fix it, and finally fill the outer mold 1 with 3.5 kg of gallium-indium alloy 2 . Put the assembled mold into the vacuum chamber and adjust the proper position to ensure that the alloy liquid can be poured into the mold smoothly.

[004...

Embodiment 3

[0047] Example 3 : Induction heating spray casting 4000mm 3 CuZrAlY amorphous rod

[0048] 1) Zr with a purity of 99.8%, Cu, Al, and Y with a purity of 99.99% according to Cu 41 Zr 49 Al 8 Y 2 The nominal composition of the batch is 30g; after 3~5 times of electric arc melting to ensure uniform composition, after mechanical crushing, it is loaded into a quartz tube with a nozzle at the bottom, and then the quartz tube is installed in a vacuum induction melting furnace.

[0049] 2) see Figure 9 , Figure 10 , Figure 11 , select the cavity size as Φ10 mm, length 60mm The inner mold 3 of the inner mold 3 is used to prepare cylindrical amorphous, and the sealing strip 4 is placed in the positioning slot 6 of the inner mold 3. After the two halves of the inner mold 3 are fastened with the fastening bolt 5, the copper inner mold 3 is inserted into the stainless steel 6 positioning slots of the outer mold 1 are fixed, and finally 2.5 kg of gallium-indium alloy 2 is fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com