Preparation method of superfine yak bone powder

A technology of yak bone meal and processing method, which is applied in the field of food processing, can solve the problems of difficult processing and utilization, and achieve the effects of complete nutrition retention, good taste and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

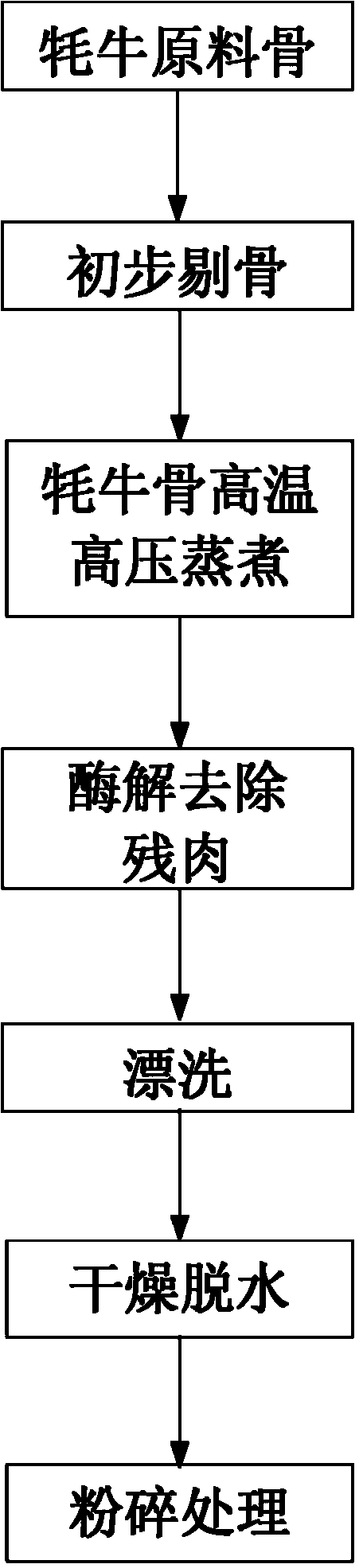

[0035] Such as figure 1 Shown, a kind of processing method of superfine yak bone meal is characterized in that, comprises the following steps:

[0036] Step 1. Preliminary deboning: remove the remaining meat from the raw yak bone, wash and drain;

[0037] Step 2, high-temperature and high-pressure cooking of yak bones: the yak bones processed in step 1 are subjected to high-temperature and high-pressure cooking at a temperature of 181°C and a pressure of 0.81Mpa for 20-30 minutes;

[0038] Step 3. Enzymatic hydrolysis to remove residual meat: Use trypsin to treat the yak bones after preliminary deboning. According to the amount of yak bones, the amount of trypsin added is: 1100U / g, and the enzymatic hydrolysis temperature is: 45°C. Time: 1.5h, PH value: 10;

[0039] Trypsin was used as the purification enzyme, and the degree of enzymatic hydrolysis and purification of yak bone was characterized by the purification removal rate. First, four single-factor experiments were carr...

Embodiment 2

[0048] Such as figure 1 Shown, a kind of processing method of superfine yak bone meal is characterized in that, comprises the following steps:

[0049] Step 1. Preliminary deboning: remove the remaining meat from the raw yak bone, wash and drain;

[0050] Step 2, high-temperature and high-pressure cooking of yak bones: the yak bones processed in step 1 are subjected to high-temperature and high-pressure cooking at a temperature of 185° C., a pressure of 0.9 MPa, and a time of 25 minutes;

[0051] Step 3. Enzymatic hydrolysis to remove residual meat: Use trypsin to treat the yak bones after preliminary deboning. According to the amount of yak bones, the amount of trypsin added is: 1200U / g, and the enzymatic hydrolysis temperature is: 50°C. Time: 2.0h, PH value: 10;

[0052] Trypsin was used as the purification enzyme, and the degree of enzymatic hydrolysis and purification of yak bone was characterized by the purification removal rate. First, four single-factor experiments we...

Embodiment 3

[0061] Such as figure 1 Shown, a kind of processing method of superfine yak bone meal is characterized in that, comprises the following steps:

[0062] Step 1. Preliminary deboning: remove the remaining meat from the raw yak bone, wash and drain;

[0063] Step 2, high-temperature and high-pressure cooking of yak bone: the yak bone processed in step 1 is subjected to high-temperature and high-pressure cooking at a temperature of 190° C., a pressure of 1 MPa, and a time of 30 minutes;

[0064] Step 3. Enzymatic hydrolysis to remove residual meat: Use trypsin to treat the yak bones after preliminary deboning. According to the amount of yak bones, the amount of trypsin added is: 1300U / g, and the enzymatic hydrolysis temperature is: 55°C. Time: 2.5h, PH value: 11;

[0065] Trypsin was used as the purification enzyme, and the degree of enzymatic hydrolysis and purification of yak bone was characterized by the purification removal rate. First, four single-factor experiments were ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com