Preparation method of oil soybean meal protein and application of oil soybean meal protein in beef sausage

A technology of oilseed bean meal and oily bean, which is applied in the protein composition, application and food preparation of vegetable seeds, and can solve the research reports on the application of oily soybean meal protein that have not yet been reported, and no one has reported on the nutritional evaluation of oily bean protein and other problems to achieve the effect of improving chewiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of oily sage soybean meal protein

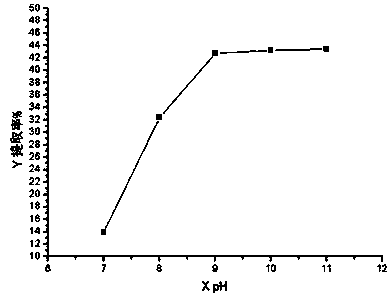

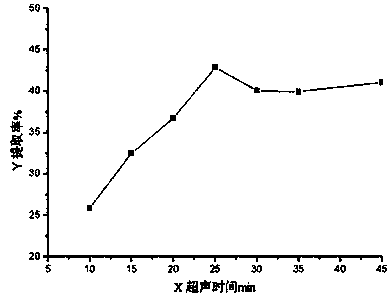

[0034]% is calculated according to the weight percentage, and the ratio of material to liquid is calculated according to the weight ratio. The oily bean cake after supercritical oil extraction is crushed through a 40-mesh to 100-mesh sieve to prepare the oily bean meal, which is degreased and crushed, and then ultrasonically assisted Liquid leaching process, the first alkaline extraction process adopts a material-to-liquid ratio of 1: (15-25) by mass ratio, ultrasonic time is 25 minutes to 45 minutes, pH value is 9-11, and the isoelectric point of oily soybean meal protein is pI= 3.8-4.4; the ratio of the second to the fifth alkali extraction to the material liquid is 1:10 by mass ratio, the pH value is 9.6, the ultrasonic time is 26 minutes, and the 3000r / min centrifugation is 15 minutes. Under the conditions of 4.4, acid precipitation for 1 hour, centrifugation at 3,000 r / min for 15 minutes, protein milk was w...

Embodiment 2

[0036] Example 2: Preparation of oily sage soybean meal protein

[0037] % is calculated according to the weight percentage, and the ratio of material to liquid is calculated according to the weight ratio. The oily soybean cake after supercritical oil extraction is crushed through a 40-mesh sieve to prepare the oily soybean meal. Extraction process, the first alkaline extraction process adopts a material-to-liquid ratio of 1:17 by mass ratio, an ultrasonic time of 26 minutes, a pH value of 9.6, an extraction rate of 44.01%, and the isoelectric point of oily soybean meal protein is pI=4.2; the second, The ratio of the three times of alkaline extraction to the material solution is 1:10 by mass ratio, the pH value is 9.6, the ultrasonic time is 26 minutes, and the centrifugation is performed at 3000r / min for 15 minutes. The protein milk was washed with 5 times the weight of water at 40°C for 30 minutes, washed 3 times, and freeze-dried to obtain the oily soybean meal protein: the...

Embodiment 3

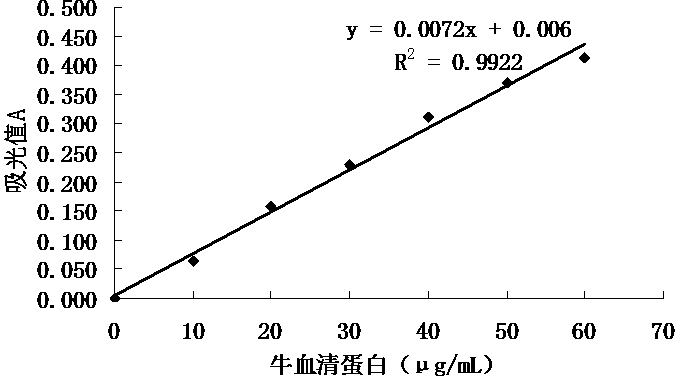

[0038] Embodiment three: Coomassie brilliant blue standard curve drawing

[0039] 1.1 Coomassie Brilliant Blue standard curve drawing: Prepare 100μg / mL bovine serum albumin, take 0mL, 0.1mL, 0.2mL, 0.3mL, 0.4mL, 0.5mL, 0.6mL respectively in test tubes, fill up to 1mL with 0.15M NaCl solution , and then add 5mL of Coomassie Brilliant Blue solution prepared in advance, after standing for 10min, measure the absorbance at 595nm, and draw the standard curve.

[0040] 1.2 Extraction rate and yield of oily soybean meal protein

[0041] Extraction rate of oily soybean meal protein = protein content in extract ÷ crude protein content in raw material × 100%

[0042] Protein yield of oily soybean meal = (protein sample weight × crude protein content) ÷ (raw material weight × crude protein content)

[0043] The crude protein content in oily soybean meal and oily soybean protein powder was determined by the Kjeldahl method N×6.25, and the protein content in the extract was determined by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com