Preparation method of carbon cloth with nanoparticle modified surface

A technology of nanoparticle modification and carbon cloth, which is applied in carbon fiber, textiles, papermaking, fiber treatment, etc. It can solve the problems of difficult control of surface uniformity, achieve excellent self-lubricating performance, high oxygen content, and improve bond strength and the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

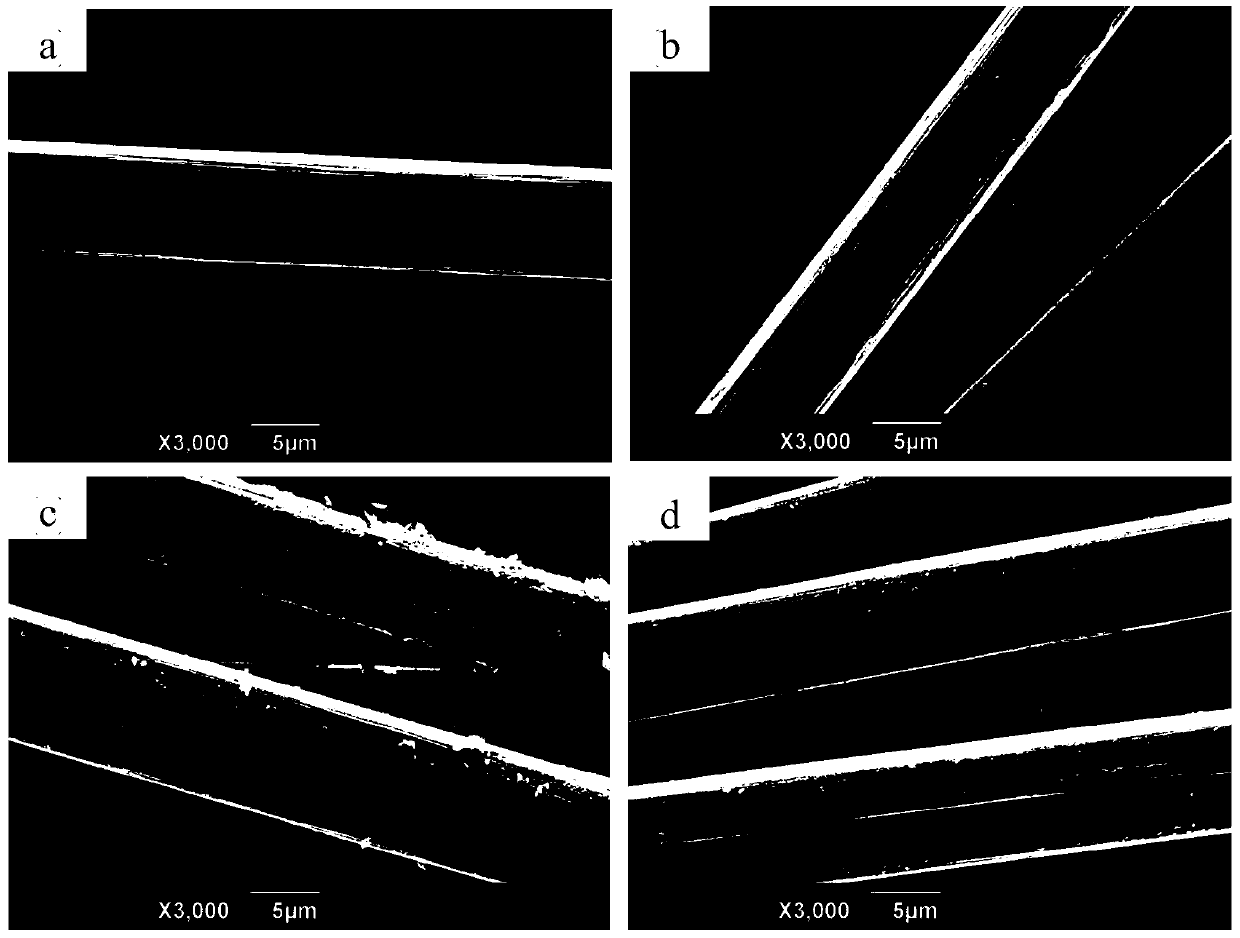

Image

Examples

Embodiment 1

[0020] 1) Cut the carbon cloth into a rectangular shape of 5cm×7cm, soak it in acetone solution for 24 hours to make it soak, take it out and dry it naturally to get sample A;

[0021] 2) Put sample A and 50ml of concentrated nitric acid into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a homogeneous reactor at 100°C for 2 hours, take out the carbon cloth after the reaction, and use deionized water to carry out Wash, and finally vacuum-dry at a constant temperature of 80°C to obtain sample B;

[0022] 3) Put sample B and 50ml of silica sol solution with a mass concentration of 3% into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor, and set the power to 300W. Insulate and react at 160°C for 60 minutes, then the temperature of the reaction system to be obtained is lowered to room temperature, sample B is taken out from the reaction system in the reactor and washed with deionized water, and fin...

Embodiment 2

[0024] 1) Cut the carbon cloth into a rectangular shape of 5cm×7cm, soak it in acetone solution for 24 hours to make it soak, take it out and dry it naturally to get sample A;

[0025] 2) Put sample A and 50ml of concentrated nitric acid into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a homogeneous reactor at 100°C for 2 hours, take out the carbon cloth after the reaction, and use deionized water to carry out Wash, and finally vacuum-dry at a constant temperature of 80°C to obtain sample B;

[0026] 3) put sample B and 50ml mass concentration of 6% silica sol solution into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor, and set the power to 400W. Insulate and react at 180°C for 90 minutes, then the temperature of the reaction system to be obtained is lowered to room temperature, sample B is taken out from the reaction system in the reactor and washed with deionized water, and finally vacuu...

Embodiment 3

[0028] 1) Cut the carbon cloth into a rectangular shape of 5cm×7cm, soak it in acetone solution for 24 hours to make it soak, take it out and dry it naturally to get sample A;

[0029] 2) Put sample A and 50ml of concentrated nitric acid into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a homogeneous reactor at 100°C for 2 hours, take out the carbon cloth after the reaction, and use deionized water to carry out Wash, and finally vacuum-dry at a constant temperature of 80°C to obtain sample B;

[0030] 3) put sample B and 50ml mass concentration of 9% silica sol solution into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor, and set the power to 400W. Insulate and react at 200°C for 120 minutes, then the temperature of the reaction system to be obtained is lowered to room temperature, sample B is taken out from the reaction system in the reactor and washed with deionized water, and finally vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com