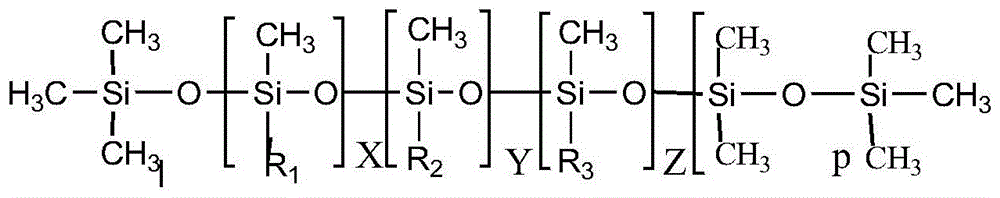

A kind of polysiloxane emulsifier modified by multifunctional group and preparation method thereof

A technology of polysiloxane and multifunctional groups, which is applied in the field of multifunctional modified polysiloxane emulsifiers and their preparation, can solve problems such as increased product viscosity, decreased product performance, and increased system viscosity. Sexual enhancement, less side effects, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

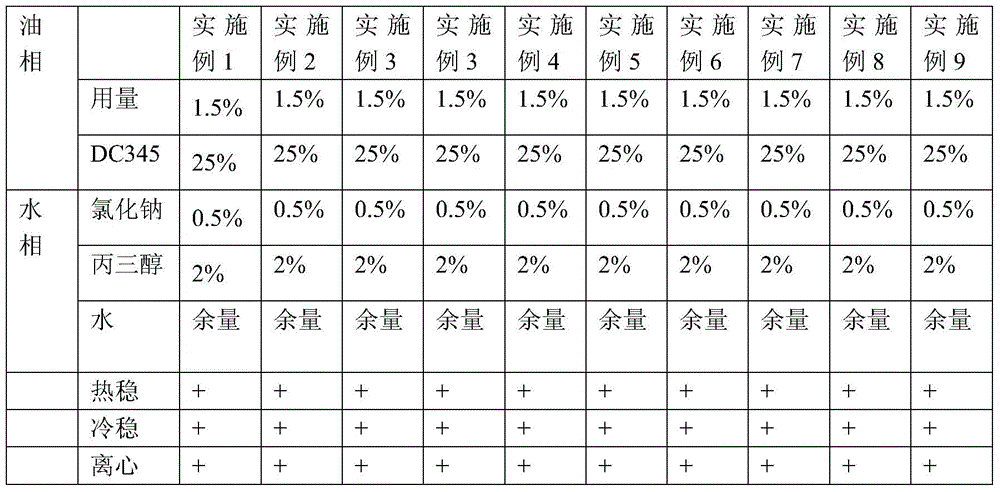

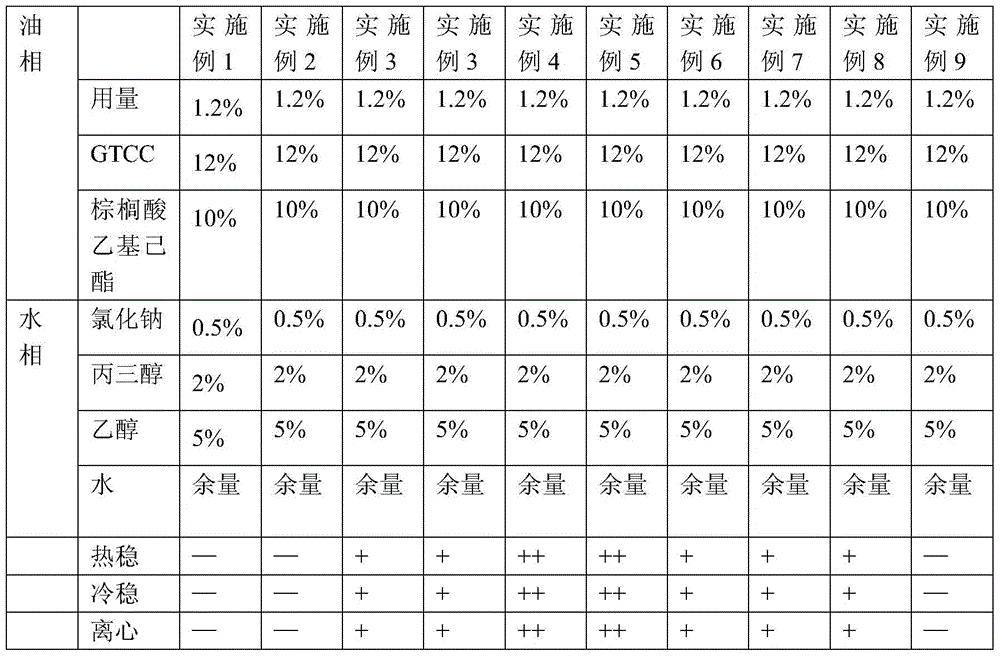

Examples

Embodiment 1

[0026] In a 500ml four-necked flask equipped with a thermometer, a stirrer, a nitrogen tube, and a condenser, 80.64g of α-16 olefin, 100.08g of low-hydrogen silicone oil with a hydrogen content of 0.2, and 24.00g of allyl Polyoxyethylene ether (M=200), 20.47g isopropanol, stir and heat up to 60℃ under nitrogen atmosphere, add 0.023g catalyst (effective content 1000ppm), stir and react at 60℃ for 12h to complete the reaction, insert Vacuum, keep the vacuum degree -0.08~-0.1MPa, 1~2h, and cool down to obtain a colorless to slightly yellow translucent or slightly turbid flowable liquid, which is a multifunctional modified polysiloxane emulsifier.

Embodiment 2

[0028] In a 500ml four-necked flask with a thermometer, agitator, nitrogen tube, and condenser, add 80.64g of α-16 olefin, 106.335g of low-hydrogen silicone oil with a hydrogen content of 0.25, and 27.00g of methyl sealant. Allyl-terminated polyoxyethylene ether (M=600), 27.00g of methoxypolyethylene glycol acrylate (M=600), 48.195g of isopropanol, stirred and heated to 70°C under nitrogen atmosphere, Add 0.145g of catalyst (effective content 1000ppm), stir the reaction at 70℃ for 10h to complete the reaction, connect to vacuum, keep the vacuum degree -0.08~-0.1MPa, 1~2h, cool down, get colorless to slightly yellow translucent or slightly Turbid flowable liquid, that is, multifunctional modified polysiloxane emulsifier.

Embodiment 3

[0030] Into a 500ml four-necked flask equipped with a thermometer, agitator, nitrogen tube, and condenser, add 80.64g of α-12 olefin, 144.11g of low-hydrogen silicone oil with a hydrogen content of 0.36, and 19.2g of butyl sealant. Allyl-terminated polyoxyethylene ether (M=400), 19.2g of methoxypolyethylene glycol methacrylate (M=400), 78.95g of isopropanol, under nitrogen atmosphere, stirring and heating to 80 ℃, add 0.342g of catalyst (effective content 1000ppm), stir the reaction at 80℃ for 8h to complete the reaction, connect to vacuum, keep the vacuum degree -0.08~-0.1MPa, 1~2h, cool down, get colorless to slightly yellow translucent Or a slightly turbid flowable liquid, which is a multifunctional modified polysiloxane emulsifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com