A kind of carbodiimide modified polyisocyanate and preparation method thereof, and catalyst system

A polyisocyanate and carbodiimide technology, applied in the field of modified isocyanates, can solve problems such as reducing the crystallization point of the product, and achieve the effects of shortening the reaction time, good switching, and reducing the formation of higher molecular weight polycyclic structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

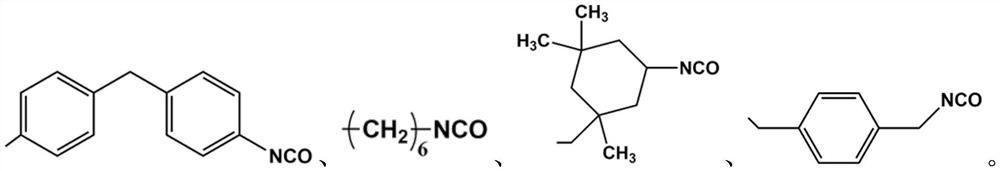

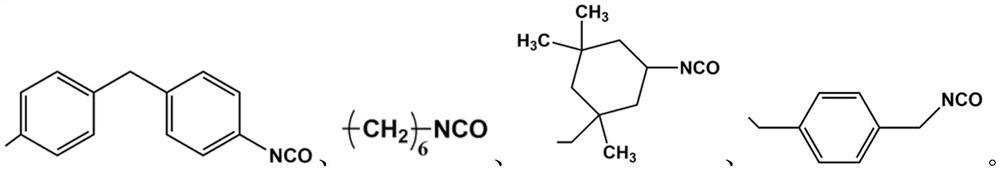

Method used

Image

Examples

Embodiment 1

[0056] Tetramethylgermanium and triethyl phosphate were mixed uniformly at a mass ratio of 1:1000 at 45°C as a compound catalyst for use. Dissolve 600 g of diphenylmethane diisocyanate in N 2 Stir in the atmosphere, add 1 wt% compound catalyst, mix uniformly and quickly heat to 150 ° C, quickly add 120 g of diphenylmethane diisocyanate after reacting for 3 hours, and at the same time pass circulating water to cool down to 80 ° C, continue stirring for 30 minutes to obtain the final product . At this time, the monomer content in the product is 75%, the composition of carbodiimide and uretonimide is 20%, and the content of the structural component of formula I is 5%. The product can be stored in liquid state for 180 days at -15°C.

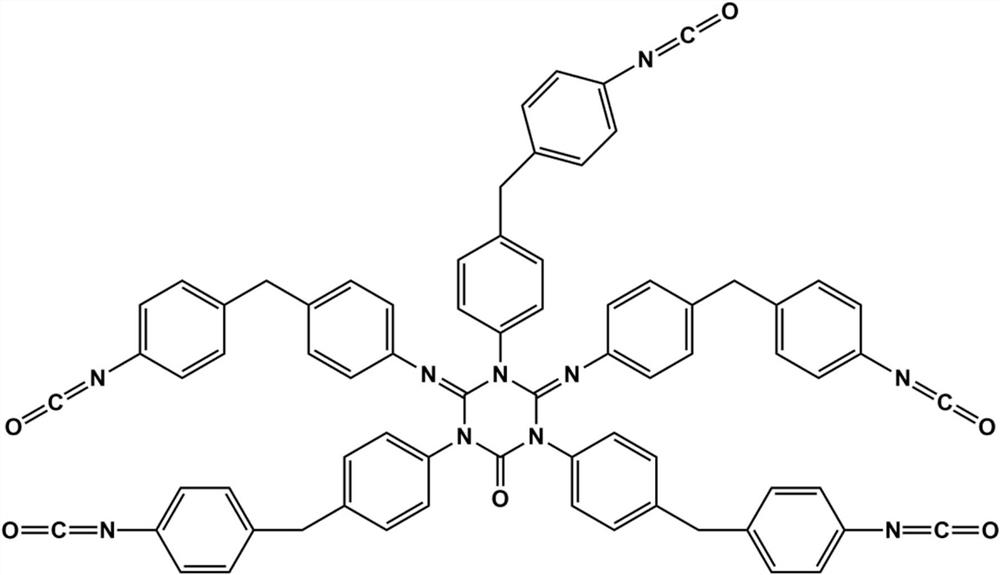

[0057] Formula I structural formula:

[0058]

[0059] The mass spectrometry results of formula I are as follows:

[0060] Chemical Formula: C 73 H 50 N 10 O 6

[0061] Exact Mass: 1162.39

[0062] Molecular Weight: 1163.24

[0063] m / z:...

Embodiment 2

[0067] Dibutyltin dilaurate and triethyl phosphate were mixed uniformly at a mass ratio of 3:1000 at 45° C. as a compound catalyst for later use. Dissolve 600 g of diphenylmethane diisocyanate in N 2 Stir in the atmosphere, add 3wt% of the compound catalyst, mix uniformly and quickly heat to 180 ° C, quickly add 180 g of diphenylmethane diisocyanate after the reaction for 2.5 hours, and at the same time pass circulating water to cool down to 80 ° C, continue stirring for 30 minutes to obtain the final product. At this time, the monomer content in the product is 72%, the composition of carbodiimide and uretonimide is 22%, and the content of the structural component of formula I is 6%. The product can be stored in liquid state for 200 days at -15°C.

Embodiment 3

[0069] Tetraethylgermanium and triethyl phosphate were mixed uniformly at 45°C according to a mass ratio of 5:1000 as a compound catalyst for use. Dissolve 600 g of diphenylmethane diisocyanate in N 2 Stir in the atmosphere, add 5wt% of the compound catalyst, mix uniformly and quickly heat to 195 ° C, quickly add 200 g of diphenylmethane diisocyanate after the reaction for 2 h, and at the same time pass circulating water to cool down to 80 ° C, and continue to stir for 30 minutes to obtain the final product . At this time, the monomer content in the product is 69%, the composition of carbodiimide and uretonimide is 23%, and the content of the structural component of formula I is 8%. The product can be stored in liquid state for 220 days at -15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com