Injection molding system for improving injection molding accuracy in mold injection

An injection molding system and accuracy technology, applied in the field of injection molding system, can solve the problems of contact error, error, melt plastic outflow, etc. between the barrel and the molding mechanism, so as to solve the error of mechanical vibration or transmission, the contact is tight and the contact is accurate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

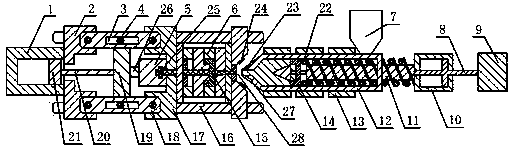

[0012] like figure 1 As shown, the injection molding system that improves the accuracy of injection molding in mold injection molding includes a power mechanism, an injection mechanism 7, a feeding mechanism, a molding mechanism 6, a demoulding mechanism and a demoulding power mechanism, and the power mechanism, the feeding mechanism, and the molding mechanism 6 , the demoulding mechanism and the demoulding power mechanism are connected sequentially, and the injection mechanism 7 is connected with the feeding mechanism; the feeding mechanism includes an internally hollow barrel 12, and the injection mechanism 7 communicates with the interior of the barrel 12, and the barrel 12 is provided with a screw rod 11 , the outer wall of the screw 11 is fitted with a spiral joint 22, the spiral joint 22 is arranged inside the barrel 12, and one end of the screw 11 is connected to the power mechanism, and the other end of the screw 11 faces the forming mechanism 6 and has a gap with the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com