Roller die core and manufacturing method thereof

A production method and roller technology, which can be applied to other household appliances, household appliances, optical components, etc., can solve the problems of lowering the 100-grid test level, affecting the yield rate, reducing the adhesion, etc., to increase the anti-oxidation ability and prolong the service life. , Overcome the effect of being easily oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

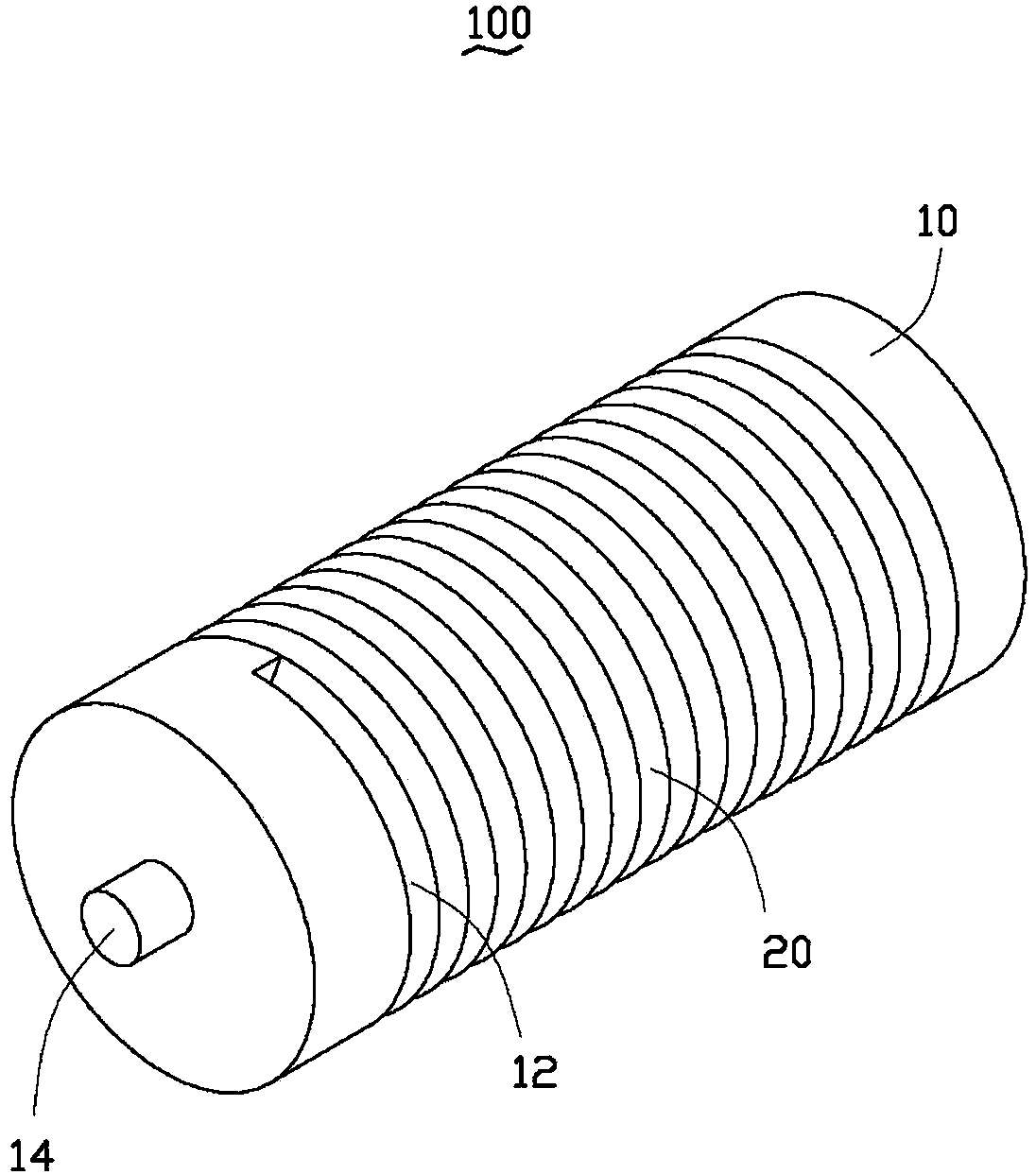

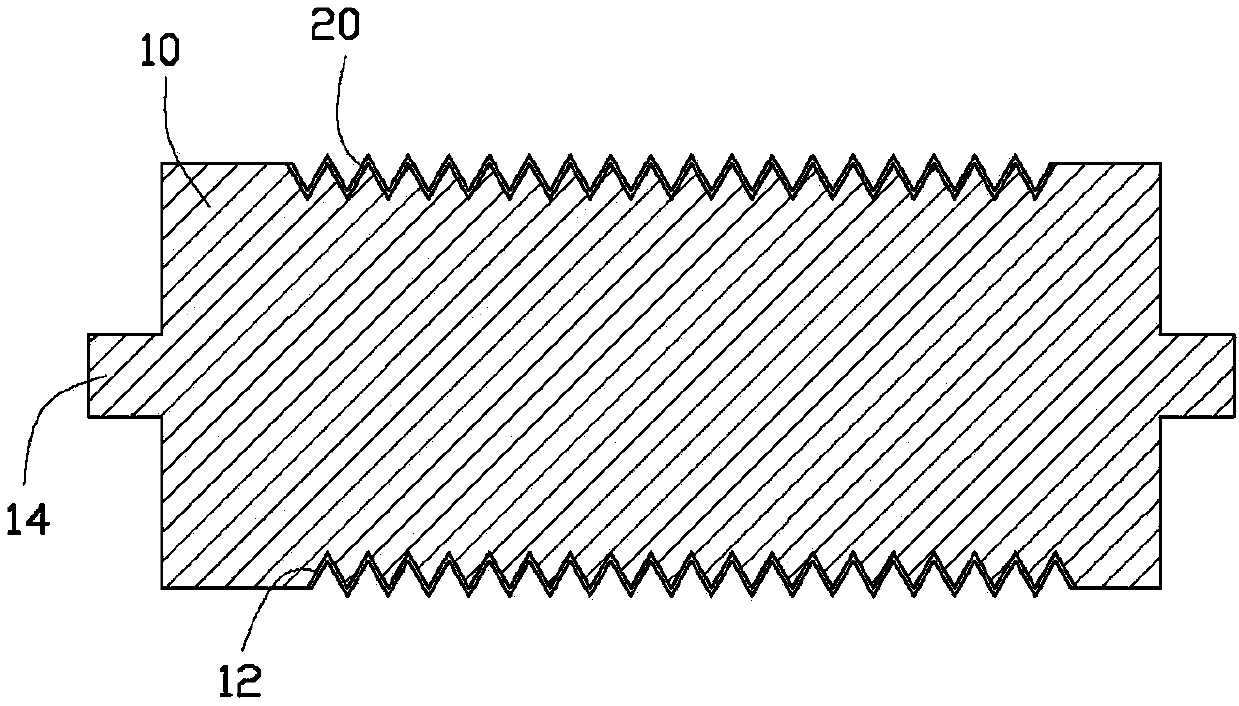

[0014] see Figure 1-2 , Figure 1-2 A roller mold core 100 is provided according to the first embodiment of the present invention. The roller mold core 100 is used to form an optical film, and the roller mold core 100 includes a copper roller 10, a microstructure 12 formed on the outer peripheral surface of the copper roller 10, a central axis 14 positioned at opposite ends of the copper roller 10, and a central axis 14 formed on the copper roller 10. A diamond-like carbon (Diamond Like Carbon; DLC) film layer 20 on the surface of the microstructure 12 , the copper roller 10 can rotate around the central axis 14 . Wherein, the microstructure 12 is a V-groove, and the depth of the V-groove is 50um (micrometer). The thickness of the diamond-like carbon film layer 20 is 200 nm (nanometer).

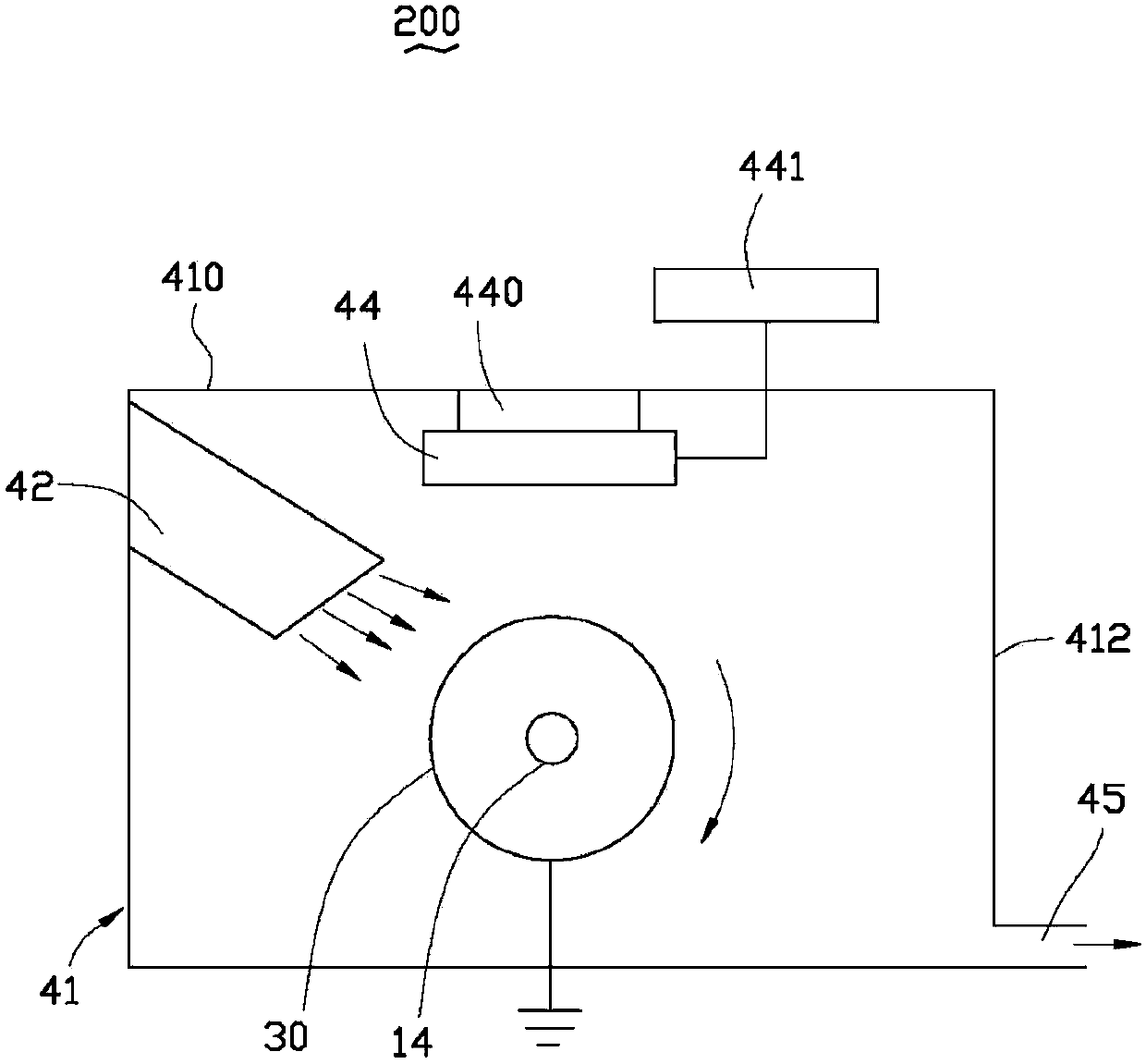

[0015] The second embodiment of the present invention also provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com