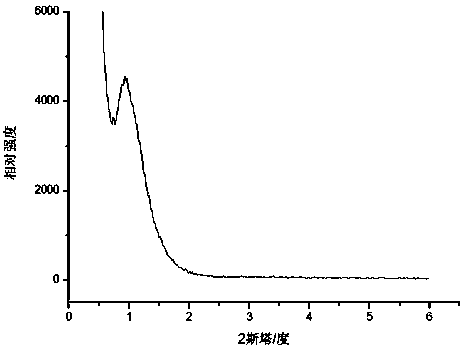

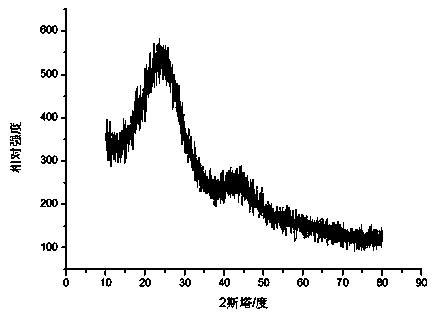

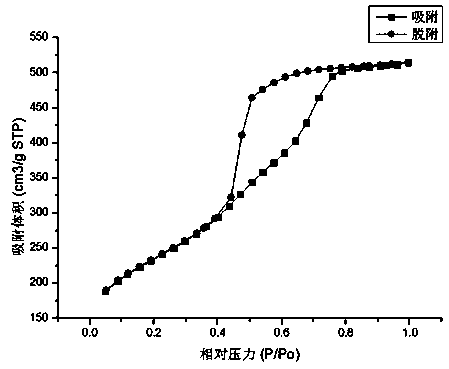

Mesopore vanadium oxide/carbon composite nano material and preparation method thereof

A nanomaterial and vanadium oxide technology, applied in the field of mesoporous vanadium oxide/carbon composite nanomaterials and their preparation, can solve the problems of unfavorable ion/electron transfer, specific surface area, pore volume and pore size, etc. The effect of simple preparation process and high theoretical specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a mesoporous vanadium oxide / carbon composite nanomaterial, specifically comprising the following steps:

[0044] (1) Disperse 0.6g of nonionic surfactant in 3g of solvent ethanol and stir at 40°C for 5min until dissolved. Dissolve 0.06g of inorganic vanadium source in 3g of solvent ammonia, stir to dissolve, and then put the dissolved inorganic Add the ammonia solution of the vanadium source to the ethanol solution in which the nonionic surfactant is dissolved, stir for 5 minutes, then add 0.09 g of organic silicon source and 0.3 g of organic high molecular polymer in sequence, and continue stirring at room temperature for 20 minutes to obtain a homogeneous solution;

[0045] The amount of the above-mentioned nonionic surfactant, organic polymer, organosilicon source, inorganic vanadium source and solvent is calculated by mass ratio, that is, nonionic surfactant: organic polymer: organosilicon source: inorganic vanadium source : The ratio of solvent...

Embodiment 2

[0066] A method for preparing a mesoporous vanadium oxide / carbon composite nanomaterial, specifically comprising the following steps:

[0067] (1) Disperse 0.6g of non-ionic surfactant in 11g of solvent ethanol and stir at 40°C for 5 minutes until dissolved. At the same time, dissolve 0.57g of inorganic vanadium source in 11g of solvent ammonia, stir to dissolve, and then put Add the ammonia solution of the dissolved inorganic vanadium source to the ethanol solution in which the nonionic surfactant is dissolved, stir for 5 minutes, then add 0.48 g of organic silicon source and 1.5 g of organic high molecular polymer in turn, and continue stirring for 20 minutes at room temperature until the formation of homogeneous solution;

[0068] The amount of the above-mentioned nonionic surfactant, organic polymer, organosilicon source, inorganic vanadium source and solvent is calculated by mass ratio, that is, nonionic surfactant: organic polymer: organosilicon source: inorganic vanadiu...

Embodiment 3

[0086] A method for preparing a mesoporous vanadium oxide / carbon composite nanomaterial, specifically comprising the following steps:

[0087] (1) Disperse 0.6g of non-ionic surfactant in 24g of solvent ethanol and stir at 40°C for 5 minutes until dissolved. At the same time, dissolve 1.2g of inorganic vanadium source in 24g of solvent ammonia, stir to dissolve, and then dissolve Add the ammonia solution of the inorganic vanadium source into the ethanol solution in which the nonionic surfactant is dissolved, stir for 5 min, then add 0.9 g of organic silicon source and 3.0 g of organic high molecular polymer in turn, and continue stirring for 20 min at room temperature until a homogeneous mixture is formed. phase solution;

[0088] The amount of the above-mentioned nonionic surfactant, organic polymer, organosilicon source, inorganic vanadium source and solvent is calculated by mass ratio, that is, nonionic surfactant: organic polymer: organosilicon source: inorganic vanadium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com