Modified mica powder for chlorinated polyethylene cable materials and preparation method thereof

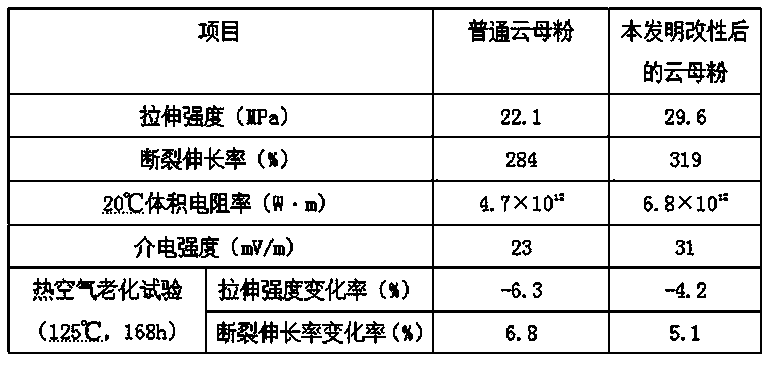

A technology of chlorinated polyethylene and mica powder, applied in the field of inorganic fillers, can solve the problems of inability to meet the requirements of multifunctional fillers, low filling function, etc., and achieve the effects of good reinforcement and filling performance and improved mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A modified mica powder for chlorinated polyethylene cable materials, which is made of the following weight (kg): mica powder 100, aromatic hydrocarbon-formaldehyde copolymer 14, diisopropyl adipate 12, limonene 2.5, silicon aluminum Carbon black 20, tertiary dodecyl mercaptan 4, trichloroisocyanuric acid 3, dicyclohexylamine 4, heavy calcium powder 8, antimony sulfide 2.5, feldspar powder 12, 4,4'-butylene-bis(6- tert-butyl-m-cresol) 2.5, diethyldiphenylthiuram disulfide 1.5, N,N'-di(β-naphthyl)-p-phenylenediamine 1, additive 3;

[0011] The preparation method of described auxiliary agent is as follows: a, get the raw material of following weight (kg): dimethyl trimethylsilyl phosphonate 4, cobalt linoleate 2, phenyl o-hydroxybenzoate 5, 2,4- Dihydroxybenzophenone 1.5, waste brick powder 12, (2,4-di-tert-butylphenyl) phosphite triester 2.5, dibutyl maleate 8, oil shale ash 7, nano-clay 6, Sorbet Tantrioleate 2.5, degreasing naphthenic acid 2, polytetramethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com