Laser processing device and method thereof

A laser processing method and laser processing technology, which are applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult elimination of melt and difficult control of taper, and achieve shortening continuous time, increasing smoothness, reducing The effect of action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention is described in detail below in conjunction with accompanying drawing:

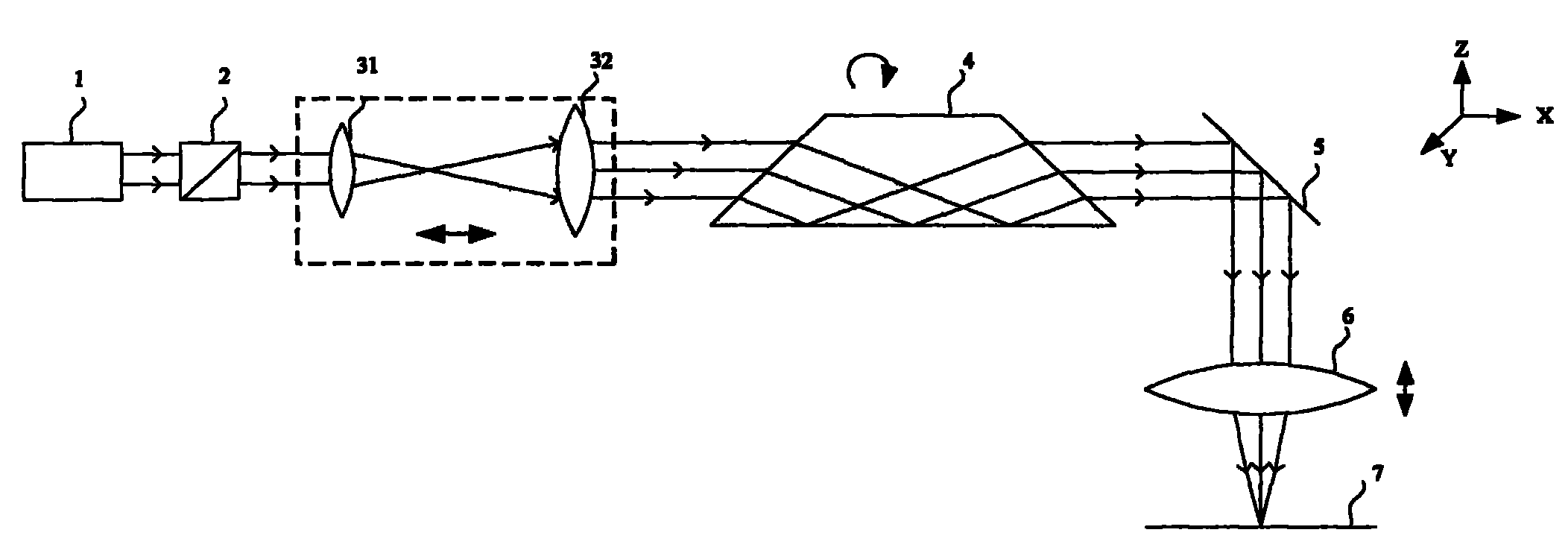

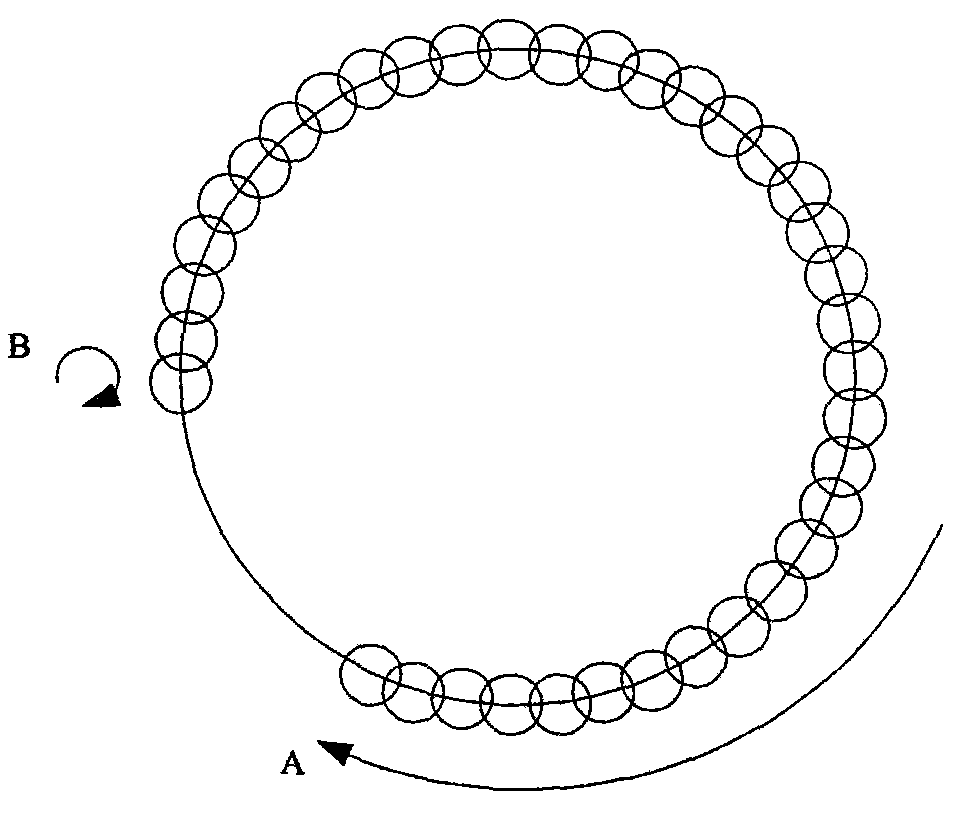

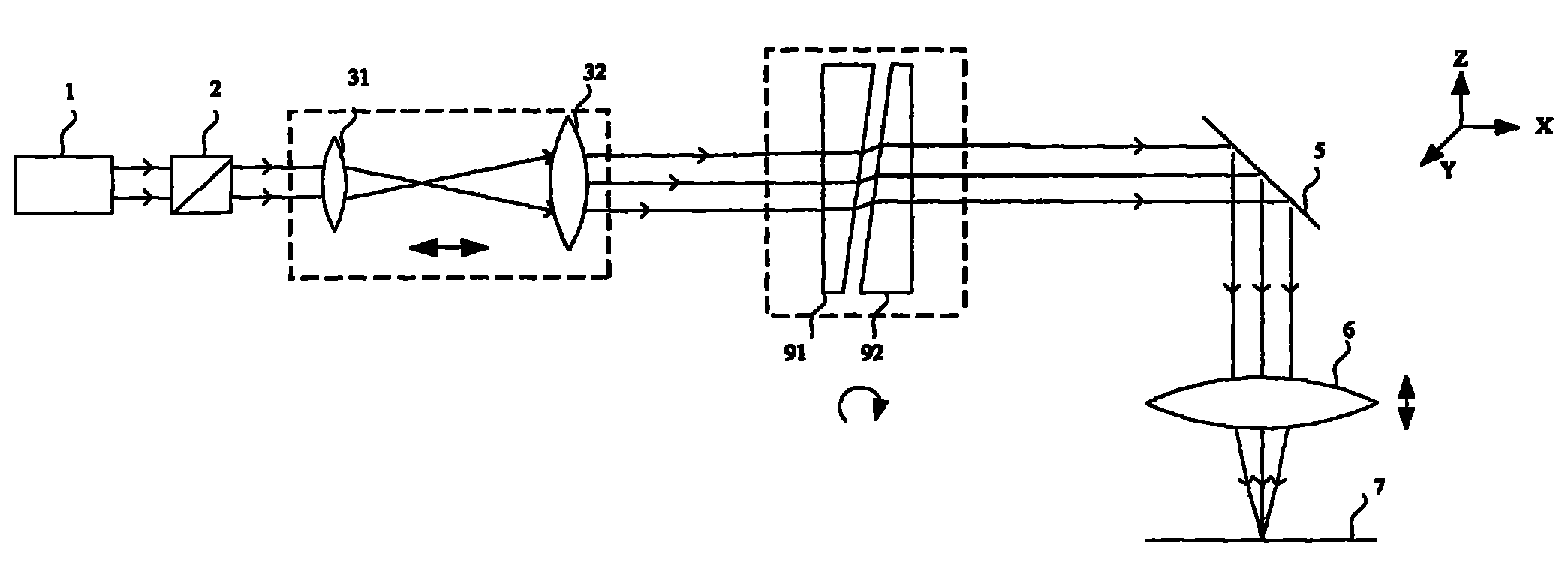

[0079] figure 1 A schematic diagram showing a laser processing apparatus according to one embodiment of the present invention. The laser processing device is composed as follows: laser 1, which is used to emit continuous or pulsed laser with high energy; electronic shutter 2, which uses its delay to block the initial unstable part of the pulsed laser to avoid irregularities in the processing surface; installed on the electric The lens group on the translation stage is composed of lens 31 and lens 32. The distance between lens 31 and lens 32 is relatively adjustable to reduce the divergence angle of the emitted laser beam and expand the spot diameter; Dove prism 4 is installed on the hollow shaft In the rotating motor, it can rotate at a high speed. When the Dove prism rotates at a speed ω, the outgoing light beam rotates at a speed of 2ω; the flat reflector 5 guides the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com