Power cable

A power cable, semi-conductive technology, applied in the direction of power cables with shielding layer/conductive layer, insulated cables, cables, etc., can solve the problems of small fault short-circuit current, poor flame-retardant effect of cables, unfavorable transportation and laying, etc., to achieve The fault short-circuit current is large, the thermal extension is consistent, and the effect is convenient for transportation and laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

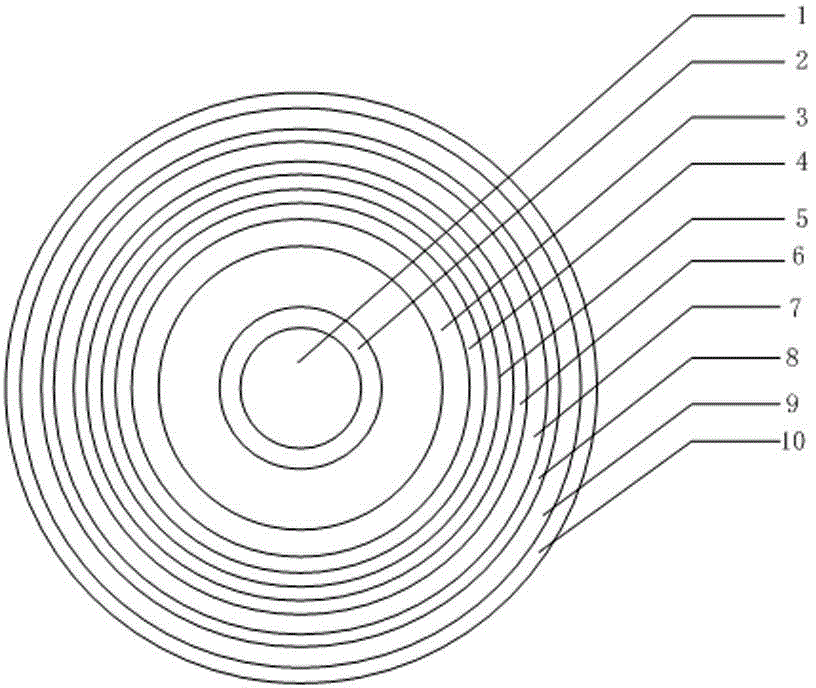

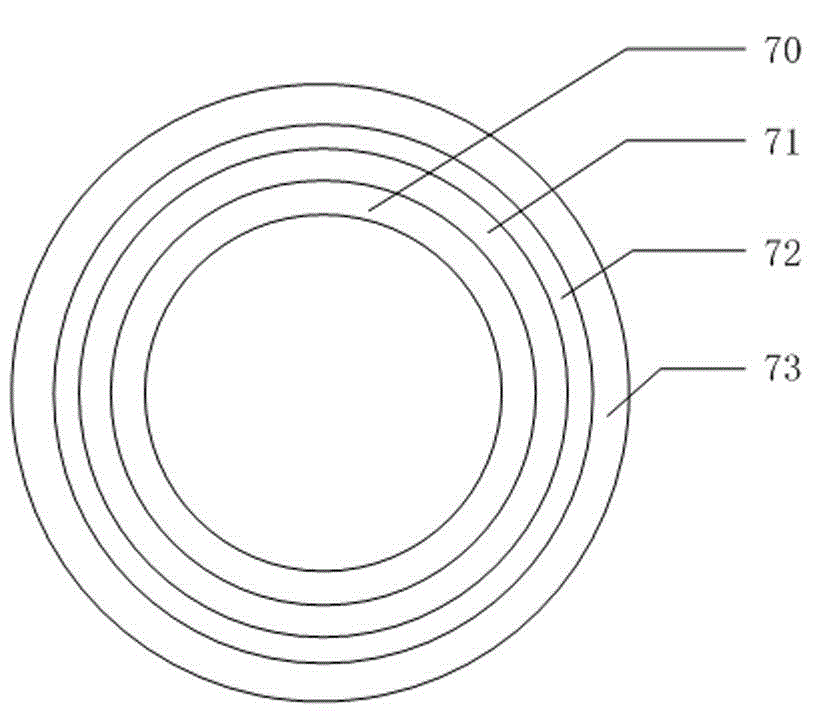

[0020] Such as figure 1 , a power cable provided by the present invention, comprising: a conductor 1 from the inside to the outside, a low-smoke halogen-free flame-retardant wrapping layer 2, a conductor shielding layer 3, an insulating layer 4, an insulating shielding layer 5, and a flame-retardant nitrile inner Sheath layer 6, shielding layer 7, corrugated steel sheath 8, outer sheath 9;

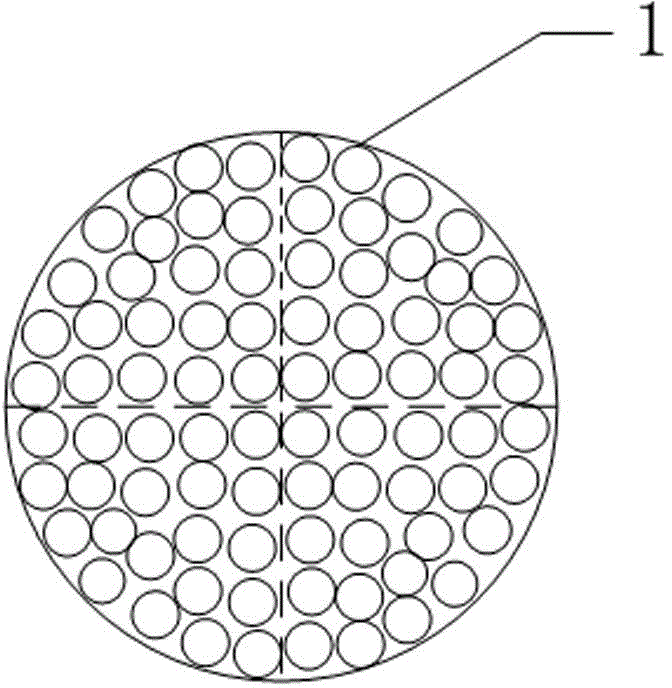

[0021] The cross section of the conductor 1 is a circle or a circle formed by combining multiple fan-shaped conductors. Such as figure 2 As shown, the cross-section of the conductor 1 is a circle formed by combining multiple fan-shaped conductors, which can effectively avoid the skin effect.

[0022] The low-smoke, halogen-free, flame-retardant wrapping layer 2 is made of halogen-free, low-smoke, flame-retardant polyolefin insulation material, which not only improves the flame-retardant ability of the cable, but also reduces the release of toxic fumes during combustion

[0023] In addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com