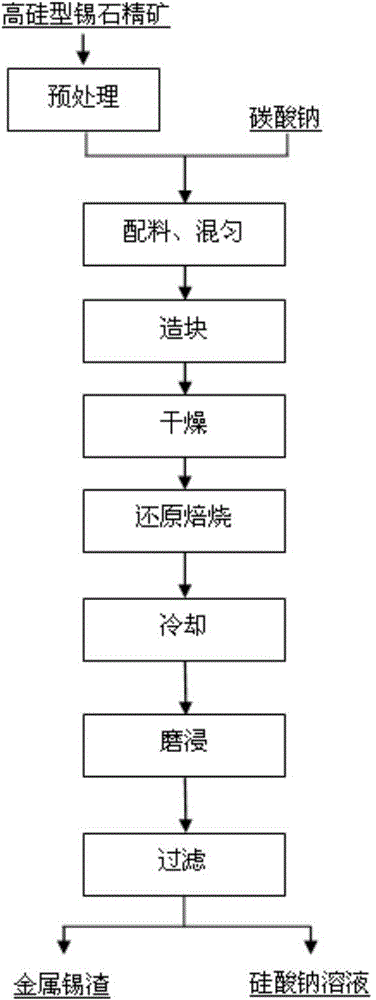

Method for preparing metallic tin and sodium silicate by utilizing high-silicon type cassiterite concentrate

A technology of metal tin and cassiterite, which is applied in the field of preparing metal tin and sodium silicate, can solve the problems of high refractory requirements for roasting equipment, affecting the physical and mental health of operators, and no production reports, etc., achieving low cost and effective separation , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Finely ground cassiterite concentrate (SnO 2 content of 72.5%), sodium carbonate according to the molar ratio of silicon dioxide and sodium carbonate in cassiterite concentrate is 1:1.05 for batching, after mixing, agglomerates, dried, and then put the dry agglomerates into a mixture of CO and CO 2 Heating and roasting in a reducing atmosphere composed of a mixed gas, where [CO / (CO+CO 2 )] × 100%=50%, the roasting temperature is 800°C, and the time is 90min; after the roasting mass is cooled, it is successively ground and filtered to obtain sodium silicate solution and metal tin slag, and the content of metal Sn in the tin slag is 97.4%, and the recovery rate of Sn was 97.2%.

Embodiment 2

[0044] Finely ground cassiterite concentrate (SnO 2 content 88.2%), sodium carbonate according to the molar ratio of silicon dioxide and sodium carbonate in cassiterite concentrate is 1:1.5; after mixing, agglomerates, dried, and then put the dry agglomerates into a mixture of CO and CO 2 Heating and roasting in a reducing atmosphere composed of a mixed gas, where [CO / (CO+CO 2 )] × 100%=40%, the roasting temperature is 1000 DEG C, and the time is 30min; after the roasting agglomerate is cooled, it is successively ground, soaked and filtered to obtain sodium silicate solution and metal tin slag, and the content of metal Sn in the tin slag is 97.1%, and the recovery rate of Sn was 97.3%.

Embodiment 3

[0046] Finely ground cassiterite concentrate (SnO 2 Content is 59.6%), sodium carbonate according to the molar ratio of silicon dioxide and sodium carbonate in cassiterite concentrate is 1:1.2 carry out batching; Agglomerate after mixing, dry, then put dry agglomerate into by CO and CO 2 Heating and roasting in a reducing atmosphere composed of a mixed gas, where [CO / (CO+CO 2 )] × 100%=60%, the roasting temperature is 925 ℃, and the time is 60min; after the roasting agglomerate is cooled, it is successively ground and filtered to obtain sodium silicate solution and metal tin slag, and the content of metal Sn in the tin slag is 98.6%, and the recovery rate of Sn was 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com