Preparation method of doped stannic oxide conductive nano powder

A technology of conductive nano and tin dioxide, applied in the field of nano materials, can solve problems such as kettle body corrosion, corrosion equipment, danger, etc., and achieve the effect of being conducive to industrialization, simple process and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 0.02mol of stannous oxalate in a 100mL beaker, add 0.06mol of 30% hydrogen peroxide in an ice-water bath, and form a transparent solution after 5 minutes of reaction; add 40mL of water to the solution and stir evenly, then add to the solution Add 0.0002mol ammonium fluoride; after fully dissolving, put the above solution in a 100mL autoclave, and place the autoclave at 180°C for 24 hours; after the reaction is completed, take out the autoclave and place it at room temperature, and the product is washed and dried. A dark green fluorine-doped tin dioxide conductive nanopowder was obtained. The powder was pressed into a disc with a diameter of 1 cm and a thickness of about 1.5 mm by a tablet press at 1.5 MPa, and the measured resistance was 38Ω / □, and □ represented the disc.

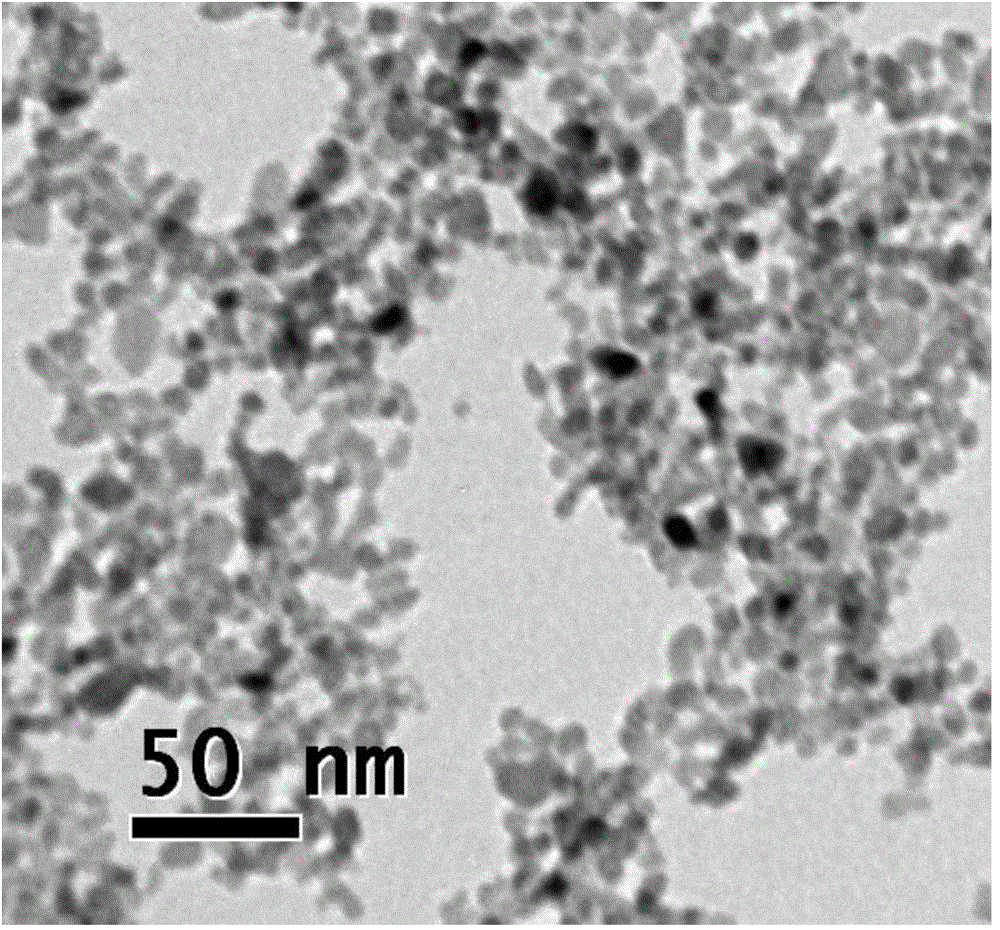

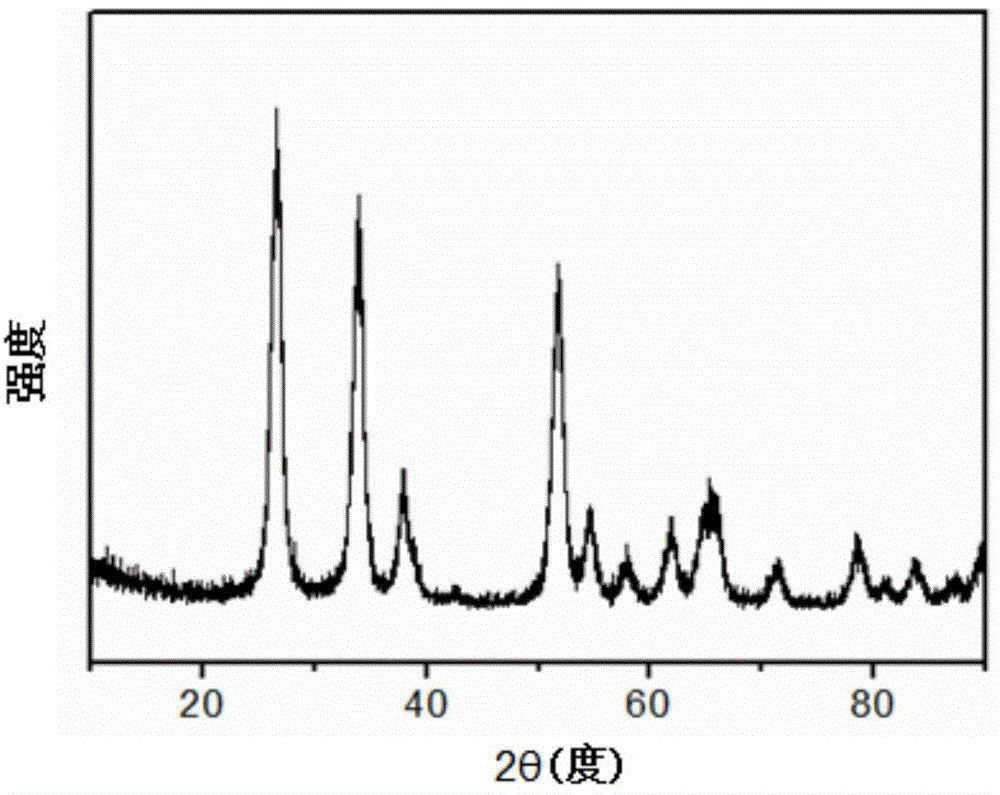

[0023] figure 1 This is the TEM image of the fluorine-doped tin dioxide conductive nanopowder prepared in Example 1. figure 1 It shows that the particle size distribution of the fluorine-dope...

Embodiment 2

[0026] Weigh 0.02mol of stannous oxalate in a 100mL beaker, add 0.08mol of 30% hydrogen peroxide in an ice-water bath, and form a transparent solution after 4 minutes of reaction; add 45mL of water to the solution and stir evenly, then add to the solution Add 0.0005mol sodium fluoride; after fully dissolving, put the above solution in a 100mL autoclave, and place the autoclave at 160°C for 48 hours; after the reaction is completed, take out the autoclave and place it at room temperature, and the product is washed and dried. A dark green fluorine-doped tin dioxide conductive nanopowder was obtained. The powder was pressed into a disc with a diameter of 1 cm and a thickness of about 1.5 mm by a tablet press at 1.5 MPa, and the measured resistance was 72Ω / □.

Embodiment 3

[0028] Weigh 0.03 mol of stannous oxalate in a 100 mL beaker, add 0.1 mol of 30% hydrogen peroxide in an ice-water bath, and form a transparent solution after 6 minutes of reaction; add 35 mL of water to the solution and stir evenly, then add to the solution Add 0.001mol antimony potassium tartrate; after fully dissolving, put the above solution in a 100mL autoclave, and place the autoclave at 200°C for 18 hours; after the reaction is completed, take out the autoclave and place it at room temperature, and the product is washed and dried. A brown antimony-doped tin dioxide conductive nanopowder is obtained. The powder was pressed into a disc with a diameter of 1 cm and a thickness of about 1.5 mm by a tablet press at 1.5 MPa, and the measured resistance was 66Ω / □.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com