A kind of cathode material for lithium-sulfur battery and lithium-sulfur battery cathode

A technology for lithium-sulfur batteries and cathode materials, applied in the field of cathode materials for lithium-sulfur batteries and cathodes for lithium-sulfur batteries, can solve the problems of poor electronic conductivity and ion conductivity of elemental sulfur, poor cycle performance of lithium-sulfur batteries, and easy shuttle effect, etc. problems, achieve the effects of controllable fiber characteristics, rich material types, and mitigation of concentrated heat release and overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

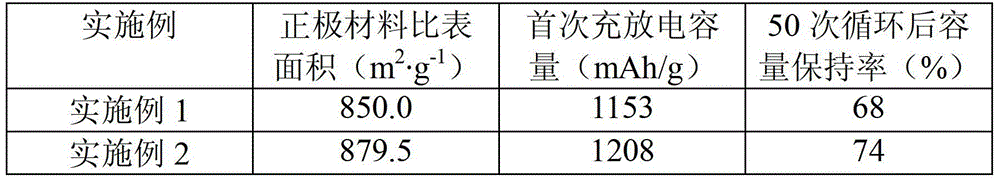

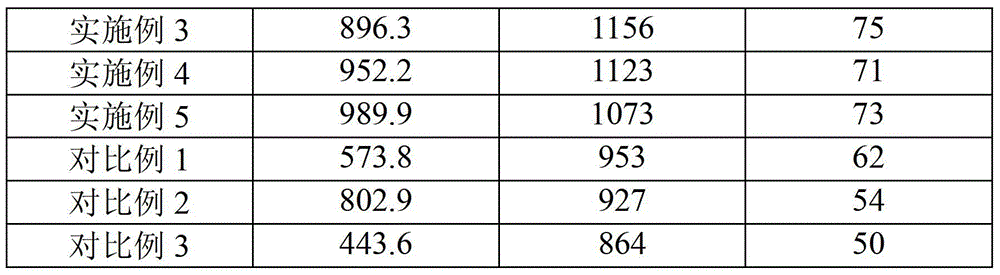

Examples

Embodiment 1

[0036] a Cut the aluminum foil, immerse it in oxalic acid solution with a concentration of 5wt%, take it out after 4 hours, dry it at 70°C, wipe the surface of the metal foil with an absolute ethanol cotton ball, and dry it;

[0037] b Preparation of graphene-doped mesoporous carbon hollow nanofibers: Graphene-doped hollow nanofibers were prepared by coaxial electrospinning technology, and then the prepared hollow nanofibers were heat-treated to obtain mesoporous carbon hollow nanofibers ;

[0038] c Nanofiber vulcanization: The prepared mesoporous carbon hollow nanofibers and elemental sulfur were placed at both ends of the glass tube respectively, and then the glass tube was placed in a tube furnace, passed through nitrogen, and heated at 500 ° C for 2 hours, Sulfur vapor diffuses and adsorbs in mesoporous carbon hollow nanofibers.

[0039]d (4) Preparation of slurry: The prepared sulfur-nanofiber composite material, polyvinylidene fluoride (PVDF), and N-methyl-2-pyrrolidon...

Embodiment 2

[0045] a Cut the aluminum foil, immerse it in oxalic acid solution with a concentration of 5wt%, take it out after 4 hours, dry it at 70°C, wipe the surface of the metal foil with an absolute ethanol cotton ball, and dry it;

[0046] b Preparation of graphene-doped mesoporous carbon hollow nanofibers: Graphene-doped hollow nanofibers were prepared by coaxial electrospinning technology, and then the prepared hollow nanofibers were heat-treated to obtain mesoporous carbon hollow nanofibers ;

[0047] c Nanofiber vulcanization: The prepared mesoporous carbon hollow nanofibers and elemental sulfur were placed at both ends of the glass tube respectively, then the glass tube was put into a tube furnace, nitrogen was introduced, and heated at 500 ° C for 2 hours, Sulfur vapor diffuses and adsorbs in mesoporous carbon hollow nanofibers.

[0048] d (4) Preparation of slurry: The prepared sulfur-nanofiber composite material, polyvinylidene fluoride (PVDF), and N-methyl-2-pyrrolidone (N...

Embodiment 3

[0054] a Cut the aluminum foil, immerse it in oxalic acid solution with a concentration of 5wt%, take it out after 4 hours, dry it at 70°C, wipe the surface of the metal foil with an absolute ethanol cotton ball, and dry it;

[0055] b Preparation of graphene-doped mesoporous carbon hollow nanofibers: Graphene-doped hollow nanofibers were prepared by coaxial electrospinning technology, and then the prepared hollow nanofibers were heat-treated to obtain mesoporous carbon hollow nanofibers ;

[0056] c Nanofiber vulcanization: The prepared mesoporous carbon hollow nanofibers and elemental sulfur were placed at both ends of the glass tube respectively, then the glass tube was put into a tube furnace, nitrogen was introduced, and heated at 500 ° C for 2 hours, Sulfur vapor diffuses and adsorbs in mesoporous carbon hollow nanofibers.

[0057] d Preparation of slurry: The prepared sulfur-nanofiber composite material, polyvinylidene fluoride (PVDF), and N-methyl-2-pyrrolidone (NMP) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com