Method for rapidly measuring content of silicon in catalyst

A rapid determination of silicon content technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of large measurement deviation, reduce the accuracy of results, etc., achieve low sample processing temperature, stable and reliable method, and determination Effects with a wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

[0024] 1. Prepare experimental instruments and medicines:

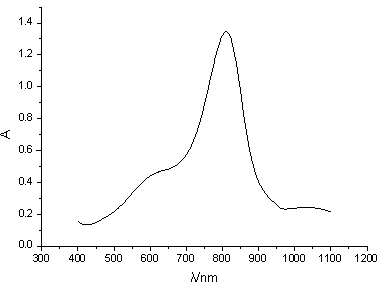

[0025] Instrument: SPECORD 200 UV-Vis spectrophotometer;

[0026] Agents: 30% sodium hydroxide solution, 3% ammonium molybdate solution, 2% ascorbic acid solution, 6mol / L hydrochloric acid solution, 99.99% high-purity silicon dioxide, absolute ethanol and acetone.

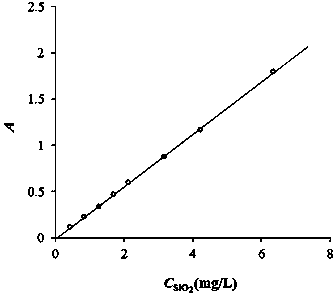

[0027] 2. Prepare the silica standard solution and the test solution of the sample to be tested:

[0028] The high-purity silica and the sample to be tested were dried at 200°C for 1 hour to constant weight, and then placed in a desiccator for use.

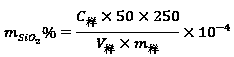

[0029] Accurately weigh 0.25g of treated high-purity silica, add 10mL of 30% sodium hydroxide solution into a polytetrafluoroethylene reactor and cover it, place it in an oven at 180°C for 30min, take it out after cooling, and add an appropriate amount of Water, then add 20mL of 6mol / L hydrochloric acid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com