Diamond grinding wheel set trimming machine and using method thereof

A diamond grinding wheel and dressing machine technology, which is applied to metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of inability to dress diamond grinding wheel groups, and achieves simple structure, convenient operation and excellent effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

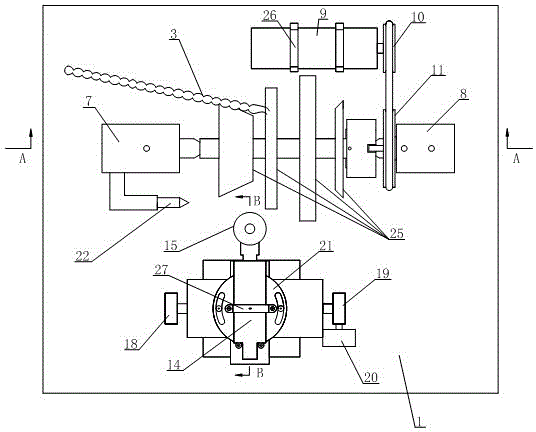

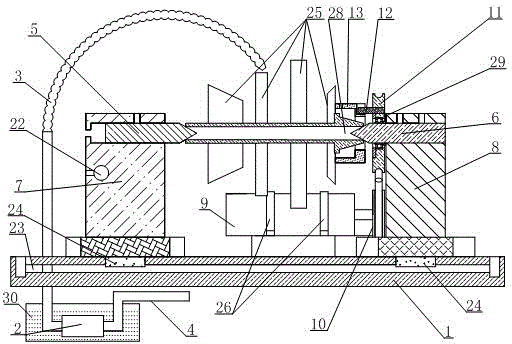

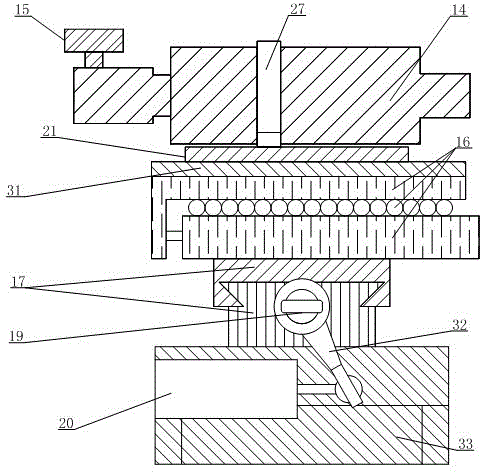

[0029] Such as Figure 1~3 As shown, the diamond grinding wheel group dressing machine includes a working platform 1, a fixing mechanism that is set on the working platform and adopts a dead center method to fix the diamond grinding wheel group, is set on the working platform and adopts a pneumatic method and a 90° grinding method A grinding mechanism for grinding the diamond grinding wheel group, and a cooling mechanism installed on the working platform to cool and clean the grinding place by jet flow. The present invention repairs the diamond steel wheel group through three mechanisms, so that the entire diamond grinding wheel group can be repaired, without disassembling the diamond grinding wheel group for grinding one by one. The fixing mechanism of the present invention adopts a dead center mode to fix the diamond grinding wheel group, which is mainly because there are center holes at both ends of the connecting rod 28 of the existing diamond grinding wheel group, so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com